In injection molding, product quality and consistency define profitability. Even a minor defect can lead to high rejection rates — increasing costs, slowing production, and wasting resources.

For many molding plants, rejection rates between 3% and 8% are common, but in high-volume production, that translates to thousands of wasted components every day.

To tackle this challenge, manufacturers are turning to automation in injection molding. From robotic handling to smart sensors and AI-based quality inspection, automation is transforming how plants maintain precision, consistency, and yield. The result — fewer rejections, faster cycles, and higher profits.

Understanding Rejection Rates in Injection Molding

Before exploring how automation helps, it’s important to understand why rejection happens in the first place.

Injection molding is a complex process where multiple parameters — temperature, pressure, cooling time, material composition, and mold quality — must align perfectly.

Even a small deviation can lead to visible defects, dimensional errors, or poor surface finish.

Common Causes of High Rejection Rates

- Inconsistent material feeding or contamination

- Temperature or pressure fluctuations during molding

- Human error in monitoring or parameter setting

- Improper mold maintenance or alignment

- Delayed detection of defects in large production runs

Every rejected part means wasted material, energy, and time. Over a production cycle, these losses can significantly impact profitability and resource utilization.

Automation addresses these inefficiencies by introducing accuracy, consistency, and continuous monitoring — ensuring that every part meets quality standards with minimal variation.

The Role of Automation in Injection Molding Plants

Automation in injection molding refers to using robots, sensors, and intelligent control systems to perform repetitive or precision-driven tasks without human error. It ensures every stage of the process, from feeding raw materials to inspecting finished parts, runs consistently and efficiently.

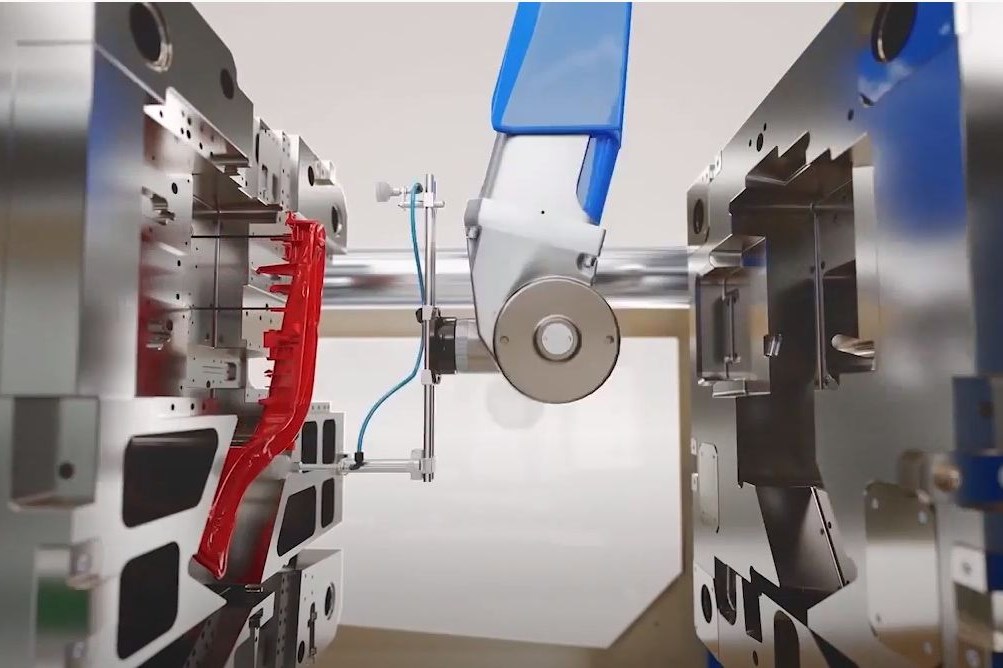

Modern injection molding plants use a combination of robotic arms, automated conveyors, machine vision systems, and data-driven monitoring tools to improve output quality and reduce rework. These systems continuously collect data on temperature, pressure, and cycle time while making real-time adjustments whenever a variation occurs.

Automation minimizes human intervention and enables round-the-clock production with consistent quality. Robots can handle part removal, insert loading, trimming, and packaging, while smart sensors verify that every molded component meets the required dimensional and visual standards.

By integrating these systems, manufacturers achieve greater control, precision, and repeatability, which directly reduces rejection rates and improves overall plant performance.

How Automation Reduces Rejection Rates in Injection Molding Plants

Automation improves quality at every stage of the molding process. From monitoring machine parameters to inspecting final products, technology ensures accuracy, consistency, and timely correction of errors.

Here are the main ways automation helps reduce rejection rates in injection molding plants.

1. Consistent Process Control

Automation systems maintain constant control over temperature, pressure, and injection speed. Even small deviations are corrected instantly, preventing issues such as sink marks, flash, or warpage.

This level of precision is difficult to achieve through manual monitoring, especially in high-volume production.

2. Real-Time Data Monitoring

Smart sensors and IoT-enabled machines collect and analyze real-time production data. Any irregularity in mold temperature or injection time triggers an alert or automatic adjustment.

This prevents a minor variation from turning into a batch-wide quality problem.]

3. Robotic Handling for Precision

Robotic arms ensure every molded part is removed carefully without distortion or surface damage. Consistent handling during cooling and trimming helps maintain uniform quality and prevents post-molding defects.

4. Machine Vision and Automated Inspection

High-speed cameras and vision systems check every molded part for defects such as surface blemishes, incomplete filling, or flash formation. Automated inspection ensures that only perfect components pass to the next stage, reducing manual inspection errors.

5. Material Handling and Feeding Automation

Automated systems precisely measure and mix materials, ensuring uniform composition and avoiding contamination. Accurate material feeding reduces short shots, burn marks, and other material-related defects.

6. Predictive Maintenance for Equipment Stability

Automated monitoring systems use predictive analytics to identify machine wear or component fatigue before a breakdown occurs. Stable, well-maintained machines ensure consistent cycle performance and quality.

7. Closed-Loop Control Systems

Modern injection molding machines use closed-loop feedback systems that constantly compare set parameters with real-time data. Any deviation is instantly corrected by the control unit, ensuring process stability and minimizing rejections.

Benefits Beyond Rejection Reduction

While the most visible impact of automation in injection molding plants is lower rejection rates, the advantages go much deeper. Automation transforms the entire manufacturing ecosystem, improving efficiency, cost-effectiveness, and scalability.

1. Improved Productivity

Automated systems can run continuously with minimal supervision, increasing overall throughput. Cycle times are shorter, setups are faster, and downtime is reduced. Manufacturers can handle larger orders without compromising on quality.

2. Reduced Material Waste

Precise control of injection parameters ensures the right amount of material is used for every part. Consistent molding reduces scrap generation, directly saving raw material costs.

3. Enhanced Energy Efficiency

Automation helps optimize heating, cooling, and clamping operations, leading to lower energy consumption. Smart systems adjust power usage according to demand, improving the energy profile of the plant.

4. Better Workforce Utilization

Instead of manually inspecting or handling components, skilled operators can focus on process optimization, maintenance, and innovation. This creates a more efficient workforce and reduces repetitive strain injuries.

5. Data-Driven Decision Making

Automation generates detailed process data that can be analyzed for trends and performance insights. Manufacturers gain better control over production planning, predictive maintenance, and cost forecasting.

6. Scalability and Consistency

Automated setups can be replicated across multiple machines or plants, ensuring consistent product quality regardless of scale. It becomes easier to standardize manufacturing processes and maintain brand reliability.

How Manufyn Helps Manufacturers Automate and Optimize Injection Molding Plants

Manufyn partners with manufacturers to simplify and accelerate their journey toward smart and automated production. By combining technical expertise with digital innovation, Manufyn enables factories to reduce rejection rates, increase productivity, and achieve consistent quality across every batch.

End-to-End Process Optimization

Manufyn helps identify inefficiencies in the current injection molding process and integrates automation where it adds the most value. From machine setup to material flow and quality control, every stage is optimized for precision and consistency.

Smart Data Integration

Through real-time monitoring systems and data analytics, Manufyn enables manufacturers to gain visibility into critical parameters such as cycle time, pressure, and temperature. This data-driven approach helps detect variations early, reducing rework and material loss.

Custom Automation Solutions

Every manufacturing plant is different. Manufyn offers customized automation and digital solutions designed to align with your specific equipment, processes, and production goals. Whether you need robotic handling, automated inspection, or sensor-based quality checks, Manufyn provides the right solution for your needs.

Sustainable and Scalable Results

Automation with Manufyn is not just about efficiency. It is about creating a sustainable and future-ready manufacturing setup that can adapt to changing market demands. The solutions are scalable, cost-effective, and built for long-term reliability.

By working with Manufyn, manufacturers can transition from reactive to predictive operations and achieve measurable results in quality, speed, and ROI.

Conclusion

Automation has transformed injection molding from a labor-intensive process into a data-driven, precision-controlled operation. By using robotics, sensors, and AI-based monitoring, manufacturers can minimize defects, reduce downtime, and deliver consistent product quality at scale.

As automation continues to evolve, it will no longer be optional but essential for every competitive injection molding plant. Partnering with experts like Manufyn helps companies unlock higher efficiency, faster production cycles, and sustainable cost savings.

Ready to lower your rejection rates and boost plant performance?

Get in touch with Manufyn to explore automation solutions that fit your factory needs.

FAQs on Automation in Injection Molding Plants

Automation improves precision, maintains consistent process parameters, and detects errors in real time. This ensures every molded part meets the desired quality standards, significantly reducing rejections.

Common types include robotic part handling, automated material feeding, machine vision inspection, and process monitoring systems. Each improves accuracy and consistency across production.

Yes. Modern automation systems are modular and scalable, making them suitable for plants of all sizes. Even partial automation can reduce rework and improve efficiency.

Sensors and monitoring tools continuously track temperature, pressure, and cycle times. Any deviation triggers alerts, helping operators correct issues before they lead to defective parts.

ROI depends on production scale, defect rate, and system integration level. However, most manufacturers recover their investment within 1–3 years through savings in scrap, labor, and downtime.

Automation reduces manual repetitive tasks, allowing employees to focus on quality assurance, process improvement, and innovation rather than routine handling.

Yes. Advanced robotic systems and AI-driven control software can handle complex geometries, multi-shot molding, and overmolding with high precision.

Automation enables predictive maintenance by tracking equipment performance data. It helps identify potential failures early and prevents unplanned downtime.

By optimizing material use, energy consumption, and waste generation, automation helps plants run more sustainably and meet environmental compliance standards.

Manufyn provides customized automation and digital integration solutions that enhance production quality, reduce rejection rates, and increase operational efficiency. The team focuses on delivering measurable, long-term improvements for every client.

Ready to Make Your Manufacturing Smarter with Manufyn?

If you’re looking to adopt modern manufacturing technologies, streamline processes, or scale production efficiently — Manufyn can help you get there.

Our team specializes in transforming ideas into scalable, sustainable, and tech-powered solutions tailored to your business goals.

Let’s build the factory of the future — together.

Get in touch with Manufyn today to start your transformation journey.