Mass production and assembly line processes are the core of modern manufacturing. They revolutionized how goods are made globally. Mass production creates standardized products in large volumes.

The assembly line provides the structured workflow that makes this efficient. These two concepts are deeply interconnected. Assembly lines enable mass production by dividing complex builds. Each workstation handles a specific, repeatable part of the process.

Manufyn harnesses this powerful relationship between mass production and assembly line. We help global businesses scale their operations effectively.

Our network connects clients with certified to automated assembly line solutions for any production scale. partners across India and facilitates access

What are the Modern Automation Technologies for Mass Production and Assembly Line

Contemporary mass production relies on advanced automation technologies. These systems enhance precision, speed, and overall cost-effectiveness for assembly line operations. Their integration has created smart, connected manufacturing ecosystems.

Industrial Robotics in Automation

Industrial robots are the foundation of automated assembly line mass production. They perform repetitive tasks with exceptional precision. Articulated robots manage complex assembly with multiple degrees of freedom.

SCARA robots excel at high-speed, precise tasks in mass production assembly line environments. Delta robots are designed for rapid pick and place operations. Collaborative robots work safely alongside human operators.

Manufyn incorporates these advanced robotic systems into its mass production solutions. We help manufacturers reach production rates unattainable with manual labor. Our approach provides access to cutting-edge assembly line robotics without massive capital investment.

Machine Vision for Mass Production

Machine vision is crucial for maintaining quality in assembly line and mass production. These systems use high resolution cameras and sophisticated algorithms. They perform real time inspections on the production line.

Machine vision guide robots for exact component placement and detect defects early. This ensures consistent product specifications in mass production assembly line operations.

Manufacturing Execution Systems and IoT

Manufacturing Execution Systems (MES) and IoT connectivity are vital for modern assembly line mass production. They allow for real time monitoring and process optimization. This enables predictive maintenance to prevent unplanned downtime in mass production facilities.

Advanced Material Handling (AGVs)

Automated Guided Vehicles (AGVs) and conveyor systems streamline material flow for mass production assembly line operations. They minimize manual handling and reduce potential bottlenecks.

These systems ensure a consistent supply of materials to assembly stations. This maintains the rhythm of assembly line mass production.

How Automated Assembly Lines Transform Manufacturing?

The implementation of automated assembly lines creates transformative effects on mass production. It fundamentally changes how manufacturers operate and compete globally.

24/7 Productivity with Automated Assembly

Automation dramatically increases output in mass production assembly line operations. It enables continuous, 24/7 operations which leads to significant cycle time reduction. Production speeds remain consistent without fatigue in automated assembly line environments.

Manufyn’s solutions help clients achieve these mass production gains. We maintain flexibility for both high volume runs and customized batches. This lets businesses respond swiftly to market demands through efficient assembly line management.

Improving Product Quality with Automation

Automation significantly improves quality in assembly line mass production. Robotic systems achieve precision tolerances as tight as ±0.01 mm. Human error in repetitive tasks is eliminated. Assembly techniques are applied with perfect consistency in automated assembly line systems.

How Automation Enables Scalable Manufacturing

Modern automated assembly lines offer unprecedented scalability for mass production. Manufacturers can increase volumes without proportional labor cost increases.

They adapt quickly to changing product designs. Modular systems can be reconfigured for different products in mass production assembly line operations.

Safer Industrial Work Environments

Automation fosters much safer working environments for mass production. It removes workers from hazardous tasks and toxic materials which reduces injuries associated with assembly line operations.

Why Manufyn’s Automated Manufacturing Cuts Costs ?

Cost reduction is a primary advantage of automated mass production. This aligns with Manufyn’s mission of delivering cost-effective assembly line solutions.

Optimizing Labor Costs and Workforce Resources

Automated assembly lines reduce labor costs for mass production. Facilities can reduce manual labor requirements significantly. Workers are redeployed to higher-value tasks like quality control in assembly line operations.

Driving Down Material and Operational Expenses

Mass production generates substantial material cost reductions. Large volume orders secure better pricing from suppliers for assembly line needs. Precision automation can reduce scrap rates significantly in mass production assembly line operations.

Accelerating Return on Investment

The ROI timeline for assembly line automation is compelling. Most mass production implementations see first-year operational savings of 15-25%. The complete investment is often recovered within two years for assembly line mass production systems.

How Mass Production and Assembly Lines Transform Major Industries ?

Mass production benefits diverse industrial sectors through assembly line technology. Each leverages these technologies for specific operational challenges.

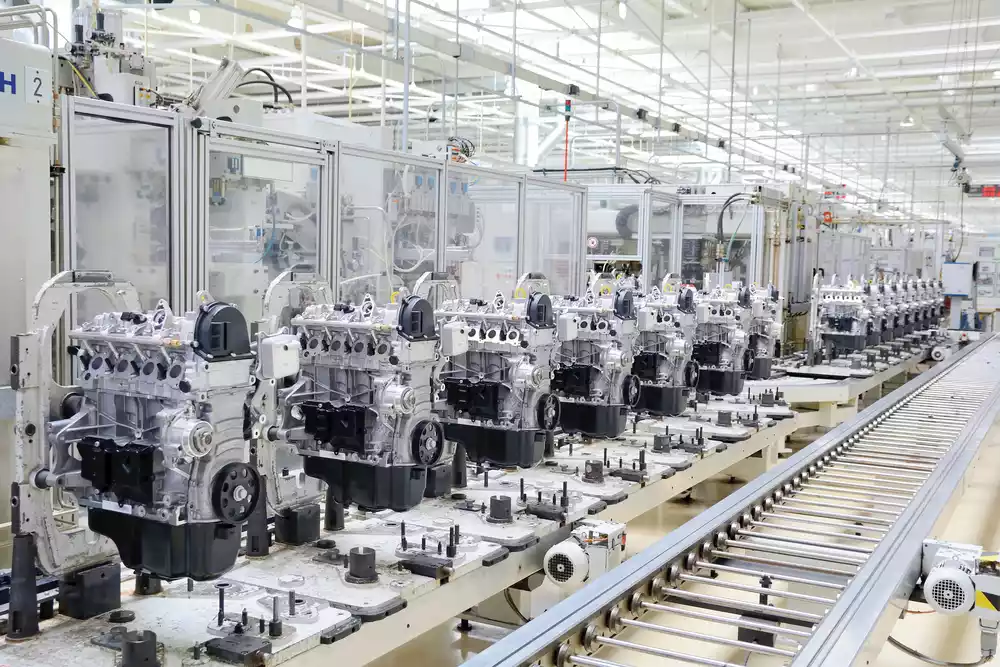

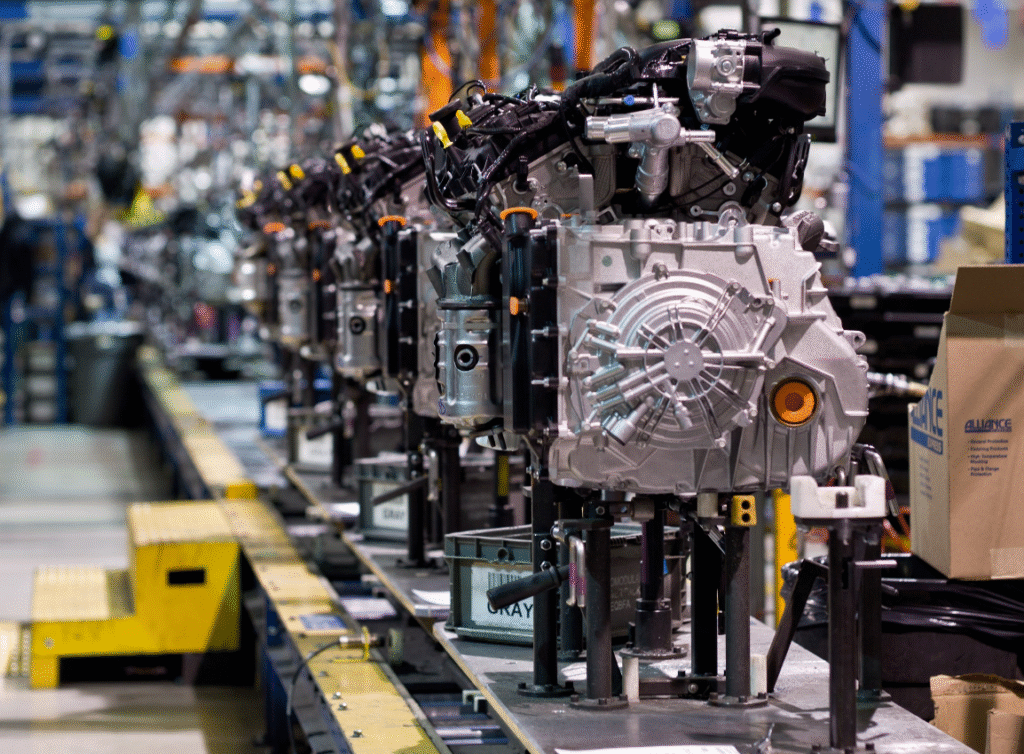

Automotive Manufacturing: Pioneer of Assembly Line Mass Production

The automotive industry pioneered assembly line mass production. Modern plants achieve remarkable outputs through automation.

They maintain critical tolerances across thousands of parts. Automated systems ensure consistent adherence to safety standards in mass production assembly line operations.

Electronics and Consumer Goods

Electronics manufacturing relies on automated assembly for mass production. It allows for the precise placement of miniaturized components. Automated inspection ensures device reliability in high-volume assembly line output.

Railway and Transport

The railway and transport industry gains significant advantages from mass production. Automated assembly lines streamline the manufacturing of locomotives, wagons, and transport components with high precision.

They ensure consistent quality, faster production cycles, and cost efficiency, while enabling scalability for large infrastructure demands.

Conclusion

Mass production and assembly line automation have reshaped manufacturing. They create opportunities to scale and reduce costs. The synergy enables high-quality goods at unimaginable volumes through assembly line mass production.

Advanced technologies like robotics and AI push boundaries of mass production assembly line capabilities. They deliver measurable benefits: major productivity increases and cost reductions in assembly line operations.

Manufyn is pivotal in this transformation of mass production. We provide access to India’s advanced manufacturing without large capital investment. Our support democratizes access to world-class automated assembly line manufacturing.

Frequently Asked Questions

Mass production creates large volumes of standardized products, and assembly line manufacturing makes this possible through sequential workstations that optimize workflow.

Automation enables 24/7 assembly line operations, reduces cycle times, removes bottlenecks, and ensures consistent quality.

Industries such as automotive, electronics, pharmaceuticals, and heavy industry rely heavily on assembly line technology for precision, scale, and compliance.

Manufyn connects businesses with certified Indian manufacturing partners, offering end-to-end assembly line solutions without requiring capital investment.

Most projects achieve a full return on investment within 2–3 years, with operational savings of 15–25% in the first year.

Yes. With flexible assembly line systems and strategic partnerships, even smaller businesses can scale efficiently without massive upfront costs.

Automation removes workers from hazardous tasks, reduces repetitive strain injuries, and enforces consistent safety protocols.

Automated assembly lines deliver higher quality by eliminating human error, achieving precision tolerances, and enabling real-time defect monitoring.

Automated systems allow manufacturers to quickly increase production volumes, adapt to design changes, and maintain consistent global operations.

By minimizing labor expenses, cutting downtime, and optimizing resource usage, automation significantly lowers the overall cost of mass production.

Read More

Start Your Project Today

Manufyn makes on-demand manufacturing easy. Get your quote and begin your project now