Optimize fillets and radii with Manufyn’s CNC insights.

Fillet radius design plays a critical role in CNC machining because it directly affects tool selection, machining time, surface finish, and part durability. While fillets are often added late in CAD as a finishing step, they influence manufacturability far more than most designers expect. Poor fillet choices can force smaller tools, increase chatter, and raise overall machining cost.

This guide focuses on fillet engineering decisions that matter in CNC machining. It explains how fillet corners interact with cutting tools, how radius size affects strength and cost, and how to specify fillets clearly for manufacturing. The goal is to help engineers design fillets that machine efficiently while still meeting functional and structural requirements.

Why Fillet Radius Matters in CNC Machining

- Fillet radius directly affects CNC machinability.

In CNC machining, a fillet radius determines which cutting tools can be used and how efficiently material can be removed. Smaller fillet radii force smaller tools, which reduces rigidity and increases machining time. - Sharp corners increase cutting stress and instability.

Sharp internal corners concentrate cutting forces and interrupt smooth tool motion. As a result, tools slow down, generate excess heat, and are more prone to chatter and wear. - Proper fillet engineering improves tool life.

When fillet corners are sized correctly, cutting tools maintain consistent engagement with the material. This reduces vibration, improves chip evacuation, and extends tool life across production runs. - Fillet radius influences surface finish quality.

Tight fillet corners often lead to visible tool marks and inconsistent finishes, especially in deep features. In contrast, larger fillet radii allow smoother toolpaths and more uniform surface finish. - Engineering fillets reduce stress concentration in parts.

From a structural standpoint, fillet engineering helps distribute stress at corners and junctions. This improves fatigue life and reduces the likelihood of cracking, particularly in load-bearing components. - Overly small fillet radii add cost without functional benefit.

In many cases, extremely small fillet corners do not significantly improve strength but greatly increase machining complexity. Therefore, fillet radius should be chosen to balance structural needs with CNC efficiency.

Fillet radius is a manufacturing decision, not a cosmetic one.

Although fillets are often added late in CAD, they directly affect machining strategy, tooling cost, and lead time. Designing fillet radii early helps avoid DFM revisions and production delays.

Not sure what fillet radius works best for your CNC part?

Fillet vs Sharp Corner — CNC Reality

In CNC machining, the difference between a fillet corner and a sharp corner is not cosmetic—it is fundamental to how the part is manufactured. Although CAD tools allow designers to model perfectly sharp corners, CNC cutting tools are round, which makes sharp internal corners physically impossible to machine. As a result, fillet engineering becomes a necessary part of translating design intent into manufacturable geometry.

Sharp corners force compromises during machining. They often require smaller tools, slower feeds, and additional passes, all of which increase cycle time and cost. In contrast, specifying an appropriate fillet radius allows smoother toolpaths, better chip evacuation, and more stable cutting conditions. Therefore, choosing fillets over sharp corners is a core CNC design decision, not an aesthetic preference.

Fillet Corner vs Sharp Corner — CNC Comparison

| Design Aspect | Sharp Corner | Fillet Corner |

|---|---|---|

| Machinability | Not directly machinable for internal features | Fully machinable with standard tools |

| Tool Selection | Requires very small diameter tools | Allows larger, more rigid tools |

| Cutting Stability | High risk of chatter and vibration | Smoother, continuous tool engagement |

| Machining Time | Longer due to slow feeds and extra passes | Shorter due to efficient toolpaths |

| Tool Wear | Accelerated due to force concentration | Reduced due to uniform load |

| Surface Finish | Often inconsistent near corners | More uniform and predictable |

| Overall Cost | Higher machining and tooling cost | Lower and more predictable cost |

From a CNC standpoint, fillet corners enable manufacturability, while sharp corners introduce unnecessary constraints. Consequently, fillet engineering should be applied early in the design process to ensure tooling efficiency, cost control, and repeatable quality.

Internal vs External Fillet Radius

In CNC machining, internal and external fillet radius features behave very differently. Although both appear similar in CAD, only internal fillet radius is constrained by cutting tool geometry. As a result, internal fillet corners often dictate tool selection, machining time, and achievable accuracy, while external fillets are generally more flexible.

Understanding this distinction is essential for fillet engineering. Designers who apply the same fillet radius rules to both internal and external edges often introduce unnecessary machining constraints. Therefore, fillet radius should be selected based on whether the corner is internal or external.

Internal vs External Fillet Radius — CNC Impact Comparison

| Aspect | Internal Fillet Radius | External Fillet Radius |

|---|---|---|

| Tool Limitation | Directly limited by cutter diameter | Not limited by cutter diameter |

| Effect on Tool Selection | Forces smaller tools for tight radii | Allows standard or larger tools |

| Machining Time Impact | Increases significantly with small radii | Minimal impact on cycle time |

| Risk of Chatter | High for small internal radii | Low in most cases |

| Surface Finish Consistency | Sensitive to tool rigidity | Generally easier to control |

| Cost Impact | High when radius is small | Low to moderate |

For internal fillet radius, smaller values increase machining complexity and cost. Tight internal fillet corners require slender tools that are more prone to deflection and vibration. Consequently, internal fillet radius should be as large as function allows.

External fillet radius, on the other hand, primarily affects part handling, stress reduction, and aesthetics. Since external edges are easier to access, increasing external fillet radius rarely adds machining difficulty. In many cases, generous external fillets can be added without affecting cost or lead time.

Validate fillet radius and tooling feasibility before machining.

Tool Diameter, Cutter Radius & Fillet Design

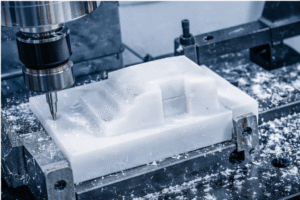

In CNC machining, fillet radius is directly tied to cutter geometry. Every internal fillet radius is produced by a cutting tool whose diameter defines the minimum achievable corner radius. Therefore, fillet engineering decisions directly influence tool selection, machining stability, and cycle time.

Smaller fillet radii force the use of smaller-diameter tools. While these tools can reach tight fillet corners, they are less rigid and more prone to deflection and chatter. As a result, machining speeds must be reduced, and additional finishing passes are often required. In contrast, larger fillet radii allow the use of stronger tools that cut faster and more consistently.

Relationship Between Fillet Radius and Cutting Tool

| Fillet Radius Requirement | Tooling Impact | Machining Outcome |

|---|---|---|

| Very small fillet radius | Requires small-diameter cutters | Lower rigidity, higher chatter risk |

| Moderate fillet radius | Allows standard tool sizes | Stable cutting and predictable finish |

| Larger fillet radius | Enables larger, rigid tools | Faster machining and lower cost |

| Mixed fillet radii | Multiple tool changes required | Increased cycle time and complexity |

From a CNC perspective, uniform fillet radii across a part simplify tooling and reduce machining time. When multiple fillet sizes are specified unnecessarily, machinists must change tools frequently, which increases setup and cycle time. Consequently, standardizing fillet radius wherever possible improves efficiency and cost control.

Designers should also consider tool reach when specifying fillet radius in deep features. Even if a fillet radius is theoretically achievable, long tool reach combined with a small cutter diameter can still introduce instability. Therefore, fillet radius should be selected in conjunction with feature depth, not in isolation.

Fillet Radius Guidelines for CNC Machining

Selecting the right fillet radius is one of the simplest ways to reduce CNC machining cost without affecting part function. In most cases, increasing fillet radius slightly allows the use of larger, more rigid cutting tools. As a result, machining becomes faster, more stable, and more repeatable.

However, fillet radius should not be chosen arbitrarily. Extremely large fillets may interfere with mating parts, while very small fillet corners significantly increase machining complexity. Therefore, fillet engineering requires balancing functional constraints with CNC capability.

Practical Fillet Radius Guidelines

| Application Area | Recommended Fillet Radius | CNC Machining Impact |

|---|---|---|

| Internal pocket corners | ≥ tool radius (preferably larger) | Enables standard tools and stable cutting |

| Deep internal features | Larger fillet radius preferred | Reduces tool deflection and chatter |

| External edges | Flexible, based on function | Minimal impact on machining time |

| Cosmetic fillets | Moderate radius | Improves finish without cost penalty |

| Load-bearing corners | Sized for stress reduction | Improves fatigue life with minor cost impact |

From a CNC standpoint, internal fillet radius has the greatest impact on cost. Tight internal fillet corners force smaller cutters and slower feeds, which increases cycle time. Consequently, designers should maximize internal fillet radius wherever mating requirements allow.

Standardizing fillet radius across multiple features further improves efficiency. When a single fillet radius is used consistently, machinists can minimize tool changes and optimize toolpaths. This approach reduces setup time and lowers overall manufacturing cost.

Engineering Fillet Design for Strength & Stress Reduction

Engineering fillet design plays an important role in improving part durability, especially in load-bearing or cyclic-load applications. Sharp corners concentrate stress, which increases the risk of fatigue failure and cracking over time. As a result, fillet engineering is often used to distribute stress more evenly across corners and transitions.

However, structural benefits must be balanced with CNC manufacturability. Extremely small fillet radii may satisfy stress calculations but significantly increase machining complexity. Therefore, fillet radius should be sized to achieve meaningful stress reduction without forcing impractical tooling or slow machining strategies.

Impact of Fillet Radius on Strength and Machining

| Fillet Design Choice | Structural Effect | CNC Machining Impact |

|---|---|---|

| Sharp corner | High stress concentration | Difficult to machine, high risk |

| Small fillet radius | Slight stress reduction | Requires small tools, higher cost |

| Moderate fillet radius | Significant stress reduction | Machinable with standard tools |

| Large fillet radius | Maximum stress relief | Minimal machining penalty (external) |

From an engineering standpoint, moderate fillet radii often provide the best balance. They significantly reduce stress concentration while remaining easy to machine with rigid tooling. In many cases, increasing fillet radius slightly delivers a disproportionate improvement in fatigue life with minimal cost impact.

Designers should also consider where fillets provide real structural value. Applying engineering fillets at load paths, junctions, and transitions improves performance, while unnecessary fillets in non-critical areas may add modeling effort without functional benefit. Consequently, fillet engineering should be applied selectively and intentionally.

Balance strength and manufacturability with expert DFM feedback.

Fillet Radius and Surface Finish Interaction

Fillet radius has a direct influence on achievable surface finish in CNC machining. As fillet corners become tighter, cutting tools must slow down and follow more complex toolpaths. Consequently, small fillet radii often result in visible tool marks and inconsistent finishes, especially in deep or internal features.

Larger fillet radii allow smoother tool motion and more stable cutting conditions. This improves chip evacuation and reduces vibration, which leads to a more uniform surface finish. Therefore, surface finish requirements should always be evaluated together with fillet radius, not specified independently.

How Fillet Radius Affects Surface Finish

| Fillet Radius Size | Toolpath Behavior | Surface Finish Outcome |

|---|---|---|

| Very small radius | Slow, segmented toolpaths | Higher chance of tool marks |

| Small internal fillet | Reduced tool rigidity | Inconsistent finish near corners |

| Moderate fillet radius | Smooth continuous motion | Uniform and predictable finish |

| Large fillet radius | Stable cutting engagement | Best achievable finish with CNC |

In practice, tight surface finish specifications combined with small fillet corners create conflicting requirements. To meet both, machinists may need additional finishing passes or smaller tools, which increases cycle time. As a result, designers should avoid specifying fine surface finishes on tight fillet corners unless function demands it.

When surface finish is critical, increasing fillet radius is often the most cost-effective solution. This simple change improves machining stability and surface quality without requiring secondary finishing operations.

Measuring and Specifying Fillet Radius

Accurately measuring and specifying fillet radius is essential to ensure design intent is correctly translated into CNC machining output. While fillet radii are easy to define in CAD, they must also be clear, measurable, and achievable during manufacturing. Otherwise, ambiguous specifications can lead to mismatched tooling, inspection issues, or DFM revisions.

From a practical standpoint, designers should understand both how to measure the radius of a fillet in CAD and how machinists verify it on the finished part. Aligning these two perspectives improves communication and reduces manufacturing friction.

How Fillet Radius Is Measured and Verified

| Stage | Method | Practical Considerations |

|---|---|---|

| CAD design | Radius dimension or feature callout | Must reflect true internal or external fillet |

| Technical drawing | Explicit radius value (R) | Avoid vague notes like “typical fillet” |

| CNC machining | Tool radius defines internal fillet | Limited by cutter diameter |

| Inspection | Radius gauges, CMM, optical tools | Access may be limited in deep features |

In CAD, fillet radius should be dimensioned clearly, especially when multiple fillet sizes exist on a part. Using consistent naming and avoiding mixed radii where unnecessary helps machinists select appropriate tools. Therefore, standardizing fillet radii across features simplifies both machining and inspection.

During inspection, internal fillet corners can be difficult to measure directly, particularly in deep pockets. As a result, machinists often rely on indirect verification methods such as tool selection confirmation or CMM probing where access allows. Designers should be aware that extremely tight fillet tolerances may be difficult or costly to verify in production.

Clear fillet specification bridges the gap between design and manufacturing. When fillet radius values are realistic, measurable, and aligned with CNC capability, parts move through production with fewer delays and lower risk.

Design fillet radius features that machine right the first time.

Common Fillet & Radius Design Mistakes

Many CNC machining issues related to fillet radius originate from design assumptions rather than machining limitations. Although fillets are often treated as minor features, poor fillet engineering choices can significantly increase machining time, tool wear, and inspection difficulty. Recognizing these common mistakes helps avoid unnecessary DFM feedback and production delays.

Frequent Fillet & Radius Errors in CNC Machining

| Design Mistake | Why It Causes Problems | CNC Impact |

|---|---|---|

| Specifying very small internal fillet corners | Forces small, flexible tools | Higher chatter and longer cycle time |

| Mixing many fillet radii on one part | Requires multiple tool changes | Increased setup and machining complexity |

| Applying tight tolerances to fillets | Difficult to inspect and control | Higher inspection cost |

| Ignoring feature depth when choosing fillet radius | Long tool reach reduces rigidity | Poor finish and dimensional drift |

| Adding fillets late in CAD | Conflicts with tooling strategy | DFM revisions and delays |

One of the most common issues is over-specifying small fillet corners where larger radii would function equally well. In many cases, increasing fillet radius slightly would allow the use of standard tooling and faster machining without affecting part performance.

Another frequent mistake is inconsistent fillet usage. When multiple fillet radii are applied without functional justification, machinists must switch tools repeatedly. As a result, cycle time increases and repeatability decreases. Standardizing fillet radii wherever possible improves both efficiency and quality.

Best-Practice Checklist for Fillet & Radius Design

Effective fillet engineering balances functional requirements with CNC manufacturability. Before releasing a design for machining, engineers should review fillet and radius features with tooling, access, and inspection in mind.

Fillet & Radius Design Best Practices

| Design Area | Best-Practice Guidance |

|---|---|

| Internal fillet radius | Use the largest radius that function allows |

| External fillet radius | Apply freely for stress relief and safety |

| Tool compatibility | Match fillet radius to standard cutter sizes |

| Depth considerations | Increase fillet radius for deep features |

| Radius consistency | Standardize fillet sizes across the part |

| Tolerances | Specify only when function requires it |

From a CNC standpoint, internal fillet radius is the most critical factor. Larger internal radii enable rigid tooling, smoother toolpaths, and predictable surface finish. Consequently, fillet radius should be treated as a machining decision early in the design process.

Designers should also consider inspection and repeatability. Fillets that are easy to machine but difficult to measure introduce quality risk. Choosing realistic, measurable fillet radii ensures smoother transitions from design to production.

Frequently Asked Questions

What is a good fillet radius for CNC machining?

A good fillet radius is the largest value that does not interfere with part function or mating geometry. From a CNC standpoint, larger fillet radii allow the use of bigger, more rigid tools, which improves machining stability, surface finish, and cost efficiency.

Why do small internal fillet corners increase machining cost?

Small internal fillet corners force the use of small-diameter cutting tools. These tools are less rigid and require slower cutting speeds, which increases cycle time and tool wear. As a result, tight fillet corners significantly raise machining cost without always adding functional value.

How small can a fillet radius be machined?

The minimum fillet radius that can be machined is limited by available tool diameters and feature depth. While very small fillet radii are possible, they often require long, slender tools that are prone to deflection. Therefore, extremely small fillet radii should be avoided unless absolutely necessary.

How does fillet radius affect tool life?

Fillet radius directly affects tool engagement and cutting stability. Larger fillet radii allow smoother tool motion and reduce vibration, which extends tool life. In contrast, tight fillet corners concentrate cutting forces and accelerate tool wear.

Are fillets required for structural strength?

In many cases, yes. Engineering fillets reduce stress concentration at corners and transitions, which improves fatigue life and reduces cracking risk. However, fillet size should be chosen to balance structural benefit with CNC manufacturability.

How do machinists measure fillet radius?

Machinists measure fillet radius using radius gauges, CMMs, or optical inspection tools, depending on access and tolerance requirements. Internal fillet corners in deep features can be difficult to measure directly, which is why realistic fillet sizes and tolerances are important.