Poor fixturing causes errors—Manufyn reviews workholding early.

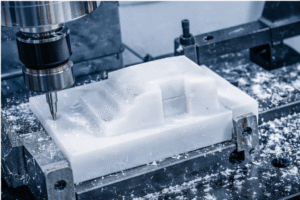

CNC machining accuracy doesn’t start at the spindle — it starts at fixturing. A machine can be perfect, the toolpath can be correct, but if the part isn’t held with the right support, the result will fail. This is why cnc workholding fixtures directly influence tolerance, cycle time, tool wear, surface finish, and repeatability across batches.

A cnc fixture is responsible for:

- Locating the workpiece correctly (datum control)

- Holding it stable against cutting forces

- Preventing deflection, vibration, and lift during passes

- Repeating the exact origin point every time

If any of those break, tolerances drift, finishes degrade, and scrap cost increases. This is why fixturing is considered the point of truth in machining.

Why Fixturing Comes Before Tooling Strategy

| Input | Controlled By |

|---|---|

| Dimensional stability | Fixturing contact points |

| Vibration / chatter | Clamp direction + rigidity |

| Surface finish | Pressure application + jaw material |

| Cycle time | Setup repeatability |

| Tool life | Force distribution during cutting |

Even the best CAM programming can’t compensate for unstable workholding. Good fixturing prevents problems before they exist — bad fixturing creates problems you can’t fix later.

Whether using standard setups or custom workholding fixtures, the role of fixturing is to neutralize forces before the tool engages — not after.

Types of Workholding Solutions Used in CNC Machining

Different parts need different holding strategies — there is no universal fixture that works for everything. Choosing the wrong setup leads to chatter, tolerance drift, and scrap. Choosing the right one stabilizes the entire machining workflow.

Common Workholding Solutions & Where They Fit

| Workholding Type | Best For | Why It’s Used |

|---|---|---|

| Vices & Clamps | Standard block/plate machining | Fast setup, general purpose |

| Soft Jaws | Contoured/irregular shapes | Protects material, prevents distortion |

| Fixture Plates | Multiple identical parts | Reduces setup time, boosts repeatability |

| Modular Fixturing Systems | Frequent design changes | Reusable without re-building fixtures |

| Collets & Chucks | Cylindrical parts on lathe/turning | Concentricity + rotation stability |

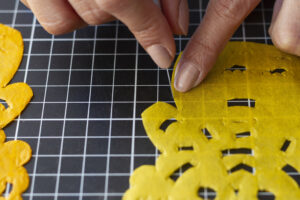

| Vacuum Fixtures | Thin or flat parts | Spreads pressure, avoids warping |

| Custom Workholding Fixtures | High-value geometry | Required when standard tools fail |

When Custom Workholding Fixtures Are Mandatory

Use custom fixtures when:

- The part has no flat reference surface

- Irregular geometry prevents vice contact

- Finish-critical surfaces must avoid clamp marks

- Toolpaths need access to all sides without repositioning

- High-volume repeatability requires a fixed locating method

A machining fixture or a fully engineered custom workholding fixture delivers consistency that operator skill alone cannot. This is why scalable production depends more on fixturing decisions than tool selection.

Not sure which fixture type your part requires?

Share your CAD model — we’ll identify the correct workholding approach before machining.

Custom Workholding Fixtures vs Standard Fixtures

Not every part requires a custom fixture — but the parts that do cannot run reliably without one. The decision is not emotional; it’s technical and financial. You choose standard workholding when geometry is simple, and you invest in custom workholding fixtures when geometry, tolerance, or volume makes inconsistency more expensive than the fixture itself.

When Standard Fixtures Are Enough

Use standard vices, clamps, plates, or soft jaws when:

- The part has flat, machinable surfaces

- Geometry isn’t interrupted by critical edges

- Tolerance band is moderate

- Setup time doesn’t affect cost-per-part

- Run quantity is low / prototype level

Example: 6061 aluminum plates, basic pockets, prototype brackets.

When You MUST Build a Custom CNC Fixture

A custom workholding fixture is mandatory when:

- There are no flat or parallel reference surfaces

- Thin walls risk deflection under pressure

- Parts distort with traditional clamping force

- Toolpaths need 360° access without repositioning

- Operators cannot repeat the same setup consistently

- Production needs cycle time control to protect margins

ROI Logic:

A custom fixture costs more upfront, but pays back through:

- Lower setup time

- Lower reject/scrap rate

- Reduced operator dependency

- Higher repeatability → stable tolerance across batches

| Project Stage | Fixture Type |

|---|---|

| Prototype | Standard, modular, soft jaws |

| Pre-Production (10–200 pcs) | Hybrid or modular with locator points |

| Production (200–10,000 pcs) | Dedicated CNC fixture engineered for cycle time |

| Export / Recurring Supply | Fully documented machining fixture for repeat orders |

Choosing the right machining fixture prevents tolerance drift, cycle-time loss, and rework — which is where shops lose money without realizing it.

Not sure if your part needs standard or custom workholding?

We’ll evaluate the geometry and tell you the cheapest reliable path — not the most expensive one.

Workholding Requirements by Material Type

Different materials react differently to clamping pressure, vibration, and heat. That means fixturing is not universal — the solution depends on what the part is made of.

Workholding by Material Performance

| Material | Workholding Requirement | Why |

|---|---|---|

| Aluminum (6061/7075) | Rigid clamping, balanced load | Prevents chatter in deep pocketing |

| Stainless & Carbon Steel | High-force clamps, stronger backing | Metal resists cuts → stability needed |

| Brass & Copper | Soft jaws to avoid surface scarring | Aesthetic & conductive parts need clean finish |

| Plastics (ABS / Delrin / PC) | Lower clamp force, distribution pads | Prevents deflection and part deformation |

| Composites | Vacuum or distributed load | Avoids crushing, fiber damage & delamination |

| Titanium | Maximum rigidity + coolant focus | Heat + pressure → must avoid micro-movement |

Why This Matters for Accuracy

If fixturing pressure doesn’t match material behavior:

- Thin walls bow

- Holes go out of round

- Edges chip or crush

- Tolerances shift after cooling

- Toolpath corrections stop working

The fixture decides the outcome before the tool touches the part.

This is why correct workholding solutions protect material integrity and cycle efficiency — the goal is control, not just clamping.

Need fixture guidance by material?

Share the material + CAD file and we’ll recommend clamp strategy, jaw type, and load direction.

Fixturing for 3-Axis, 4-Axis & 5-Axis CNC Machining

Workholding must match machine capability. The more axis movement involved, the more critical fixturing becomes. A 3-axis setup can survive with basic clamping, but a 5-axis environment needs rotational clearance, zero-point locking, and interference-free toolpaths. This is why one universal fixture can’t fit all machining scenarios.

How Fixturing Changes by Machine Type

| Machine Type | Workholding Priority | Best Fixture Approach |

|---|---|---|

| 3-Axis CNC | Flat stability + reference datum | Vices, clamps, fixture plates |

| 4-Axis CNC | Rotational clearance & side access | Modular fixtures, side-support jaws |

| 5-Axis CNC | Multi-angle tool access & articulation | Zero-point locating, custom nests, soft jaws shaped to geometry |

5-Axis Fixture Rules

To make 5-axis machining efficient:

- Leave clearance under part for tool swing

- Avoid clamp locations blocking toolpath arcs

- Use positive-location features (pins, nests, tapers)

- Use custom workholding fixtures when geometry is irregular

A cnc fixture for 5-axis machining is not just a clamp — it’s a locating system, vibration controller, and toolpath enabler.

Why Zero-Point Systems Matter

Zero-point locking systems reduce setup time from:

⏱ 45–90 minutes → to → 5–10 minutes

for repeat runs.

This alone improves cost-per-part and batch profitability without touching feeds, speeds, or CAM programming.

Modern cnc workholding fixtures are built to support machine travel, not limit it — especially on 4-axis and 5-axis programs.

Running 4-axis or 5-axis parts?

We’ll recommend a fixturing approach that reduces setup and unlocks toolpath access.

Workholding Problems & How to Fix Them (Troubleshooting Guide)

Even experienced machinists run into the same problems when fixturing isn’t dialed in. The issue isn’t always the machine or the tool — it’s often the workholding strategy.

Common Workholding Problems & Fixes

| Problem | Why It Happens | Fix |

|---|---|---|

| Vibration / Chatter | Clamp direction fights cutting force | Re-orient clamps + add secondary support |

| Part Lifting / Warp | Pressure not aligned to tool load | Add top pressure or opposing jaw support |

| Tolerance Drift | Fixture doesn’t locate repeatably | Add datum pins / zero-point locating |

| Surface Damage | Hard jaws marking the part | Switch to soft jaws or surface pads |

| Thin Wall Flex | Clamp force too high | Vacuum fixture or distribute force |

| Tool Pressure Marks | Single-sided clamping | Spread load / neutralize force vectors |

Quick Diagnostic Checklist

Before adjusting toolpaths, check:

- Is the clamp direction aligned with cutting force?

- Are surfaces clamped on non-critical faces?

- Is the workpiece supported under the tool load, not next to it?

- Is the fixture preventing movement — or assuming it won’t happen?

Truth: 80% of machinists change feed rates when they should change clamping direction.

When to Move to a Custom Machining Fixture

- Rework is increasing

- Operators struggle to repeat setups

- Tolerance windows tighten as project scales

- 5-axis access is blocked by clamp interference

- High-value parts are being scrapped

Properly engineered workholding solutions eliminate scrap risk and stabilize tolerance before scaling to production.

Scaling Workholding for Production

Fixturing strategy is not static — it evolves with volume. What works for a prototype job will fail in production. As batch size increases, the fixture must shift from “holding the part” to controlling repeatability, cycle time, and cost-per-unit. This is where scalable workholding separates profitable machining from break-even machining.

How Fixturing Scales Across Manufacturing Stages

| Stage | Fixture Type | Goal |

|---|---|---|

| Prototype (1–10 pcs) | Standard vice, clamps, modular nests | Validate geometry + toolpath feasibility |

| Pre-Production (10–200 pcs) | Hybrid soft jaws / fixture plates | Reduce setup time + protect tolerance |

| Pilot Production (200–1,000 pcs) | Dedicated machining fixture | Achieve repeatability + operator independence |

| Full Production (1,000+ pcs) | Engineered custom workholding fixtures | Reduce cycle time for margin protection |

Signs You Need to Scale Fixturing

- Setup time is becoming a cost problem

- Operators must “babysit” the part during machining

- Scrap rate rises when batch size increases

- Toolpath changes can’t stabilize vibration

- Dimensional variance appears over longer runs

The Real Value of Custom Workholding Fixtures

A properly designed cnc fixture saves more money than it costs — not through big ideas, but small, repeatable improvements:

- Faster setups

- Cleaner tool access

- Lower burr formation

- Fewer “save this part” situations

- Predictable tolerance windows

For recurring orders and export-grade supply, scalable workholding solutions are mandatory, not optional.

RFQ Requirements, CTA, & Meta Setup

A successful fixture or workholding quote depends on clarity — not guesswork. To avoid redesign loops and unnecessary back-and-forth, we ask for specific inputs up front. This protects manufacturing time, prevents tolerance conflict, and ensures the fixture actually solves the problem you’re dealing with.

What We Need to Quote a CNC Fixture

| Information | Why It Matters |

|---|---|

| CAD Model (STEP/IGES/SLDPRT) | Defines geometry + contact points |

| Critical Surfaces / “No Clamp Zones” | Prevents marking & distortion |

| Material (Aluminum, Steel, Plastic, Brass) | Controls clamping force strategy |

| Quantity / Volume Expectation | Decides standard vs custom fixture |

| Machine Type (3/4/5-axis) | Determines fixture orientation & access |

| Repeatability Requirement | Tolerance stability target |

We evaluate custom workholding fixtures based on material, geometry, volume, and machine type — not one-size-fits-all assumptions.

Frequently Asked Questions

CNC workholding fixtures are tools that secure a part during machining to maintain accuracy, stability, and repeatability. Without proper cnc workholding fixtures, tolerances drift, vibration increases, and surface finish degrades.

A cnc fixture is built for automated toolpaths and repeatable datums, while a machining fixture may be designed for manual or semi-automatic setups. In CNC operations, fixture precision directly impacts cycle time and tolerance stability.

You need custom workholding fixtures when the part has irregular geometry, thin walls, finish-critical surfaces, or requires 4-axis/5-axis access. Custom solutions reduce scrap, setup time, and operator dependency during production.

The choice depends on part geometry, material, tolerance band, machine type (3-axis, 4-axis, 5-axis), and volume. For complex shapes or repeat batches, engineered workholding solutions outperform generic clamping.

Yes. A machining fixture can be designed for any material, but clamp force, jaw type, and contact pressure must change to avoid deformation on plastics or surface scarring on metals like brass and aluminum.

To quote accurately, suppliers need a 3D CAD file, “no-clamp” zones, material type, expected quantity, machine axis information, and tolerance-critical features. This ensures the fixture solves the actual machining problem.

Yes. Workholding determines repeatability. As volume grows, fixturing shifts from generic setups to engineered cnc fixtures that reduce setup time, eliminate rework, and protect margins during production scaling.