Manufyn helps select metals for cost and accuracy.

CNC machining for metals is a subtractive manufacturing process that produces high-strength, tolerance-critical parts from materials like aluminum, stainless steel, mild steel, brass, and titanium. Unlike general fabrication or casting, a cnc machine for metal uses controlled toolpaths, rigid fixturing, and coolant-assisted cutting to maintain geometry, finish consistency, and repeatability across batches.

Companies choose CNC machining when:

- The product needs dimensional stability for assemblies

- Prototypes must behave like production parts

- Design revisions are expected before tooling

- Tooling cost (casting/molding) isn’t justified yet

- Critical surfaces require specific Ra finish values

This makes metal cnc machines ideal for functional prototypes, bridge manufacturing, and volume-ready production supply. At Manufyn, CNC machining isn’t treated as a standalone process — it’s a scalable manufacturing path. We help engineering and procurement teams stabilize designs before committing to castings or mass tooling so the part is proven before capital investment.

By combining multi-axis setups with a cnc metal milling machine workflow, we ensure that prototypes and production parts maintain tolerance integrity, even as design cycles evolve.

How CNC Machines for Metal Work

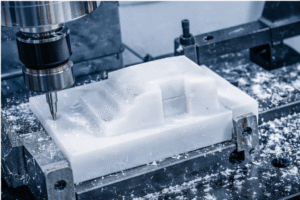

A CNC machine for metal removes material from a solid billet or forging using programmed toolpaths (G-code), spindle-controlled cutters, and rigid fixtures designed for heat and vibration stability. Performance depends on cutting forces, thermal expansion management, and chip load — which directly impact tolerance stability.

How a Metal CNC Machine Maintains Accuracy

| Control Parameter | Why It Matters for Metals |

|---|---|

| Toolpath Strategy | Prevents chatter, improves surface finish |

| Coolant Delivery | Controls heat + prevents tool wear |

| Fixturing & Clamping | Stops micro-movement during heavy cuts |

| Feed & Speed Matching | Protects cutters from premature wear |

| Tool Geometry | Required for aluminum vs stainless vs brass |

The tighter the tolerance, the more the setup matters. This is why high-precision production often requires:

- Rigid bed machines or gantry systems

- Carbide / indexable tooling

- Flood coolant or MQL systems

- Surface verification post-operation

Where CNC Metal Cutting Machines Excel

- Complex geometry that casting can’t achieve

- Low to mid-volume production without tooling

- Assembly-ready dimensions (tapped holes, pockets, slots)

- Repeatable supply programs with tolerance control

This is what differentiates CNC machining from basic fabrication, manual milling, or entry-level prototyping.

Where a hand mill can cut, a cnc metal cutting machine can produce, repeat, and supply.

For aluminum, stainless steel, and titanium parts, our cnc metal milling machine setups ensure pocketing, surfacing, profiling, and edge finishing are repeatable from prototype through production.

Now that the process is clear, the next strategic step is choosing the right metal — because machining behavior changes dramatically with material selection.

Metals That Perform Best in CNC Machining

Choosing the right metal isn’t about “what’s available” — it’s about how the material behaves under spindle load, coolant exposure, and heat transfer. Each metal responds differently to a cnc machine for metal, so material drives both quality and cost-per-part.

Performance Comparison of Common Machinable Metals

| Material | Why Engineers Choose It | Typical Parts | Machining Behavior |

|---|---|---|---|

| Aluminum 6061 / 7075 | Lightweight, strong, stable for assemblies | Housings, brackets, EV parts, aerospace components | Fast machining, excellent finish |

| Stainless Steel 304 / 316L | Corrosion resistance & hygiene compliance | Pharma fixtures, food-contact parts, marine assemblies | Harder cuts, requires coolant + rigid fixturing |

| Mild Steel / Carbon Steel | Cost-effective + durable | Jigs, plates, structural parts, machine components | Good for production supply, finish varies by cut |

| Brass / Copper Alloys | Conductive + aesthetic machining | Fittings, terminals, connectors, custom hardware | Smooth machining, low tool wear, premium surface |

| Titanium | Strength-to-weight ratio + heat stability | Aerospace mounting, medical, defense parts | Hard to machine, requires controlled toolpath + coolant |

If weight reduction, corrosion resistance, or heat stability is part of your requirement, material choice can change viability more than tolerances can.

Choosing a Metal Based on Performance Requirement

| Requirement | Best Material | Why |

|---|---|---|

| Lightweight + High Strength | 7075 Aluminum | Aerospace-grade performance |

| Food / Medical Contact | 316L Stainless Steel | Passivated, hygiene stable |

| Cost Efficiency | Mild Steel | Best prototype-to-production affordability |

| Conductivity + Finish | Brass / Copper | Electronics + premium components |

| High Temp + Load | Titanium | Metal replacement where failure is not acceptable |

Our setups for cnc machines for metal, whether in aluminum or stainless steel, are chosen based on material behavior — not generic feeds and speeds.

Not sure which metal to choose?

Share your CAD file — we’ll suggest material, tolerance range & machining strategy.

Metal CNC Machining Capabilities & Operations

Manufyn operates multi-axis setups configured to handle both prototype agility and production repeatability. The goal isn’t just machining speed — it’s tolerance stability, surface integrity, and feature consistency across batches.

Core Capabilities

| Capability | What It Delivers | Why It Matters |

|---|---|---|

| 3-Axis Machining | Standard faces, pockets, contours | Short lead time, lower machine cost |

| 4-Axis Machining | Multi-face machining, angled features | Reduces re-clamping, improves accuracy |

| 5-Axis Machining | Complex surfacing & undercuts | Aerospace & robotics geometries |

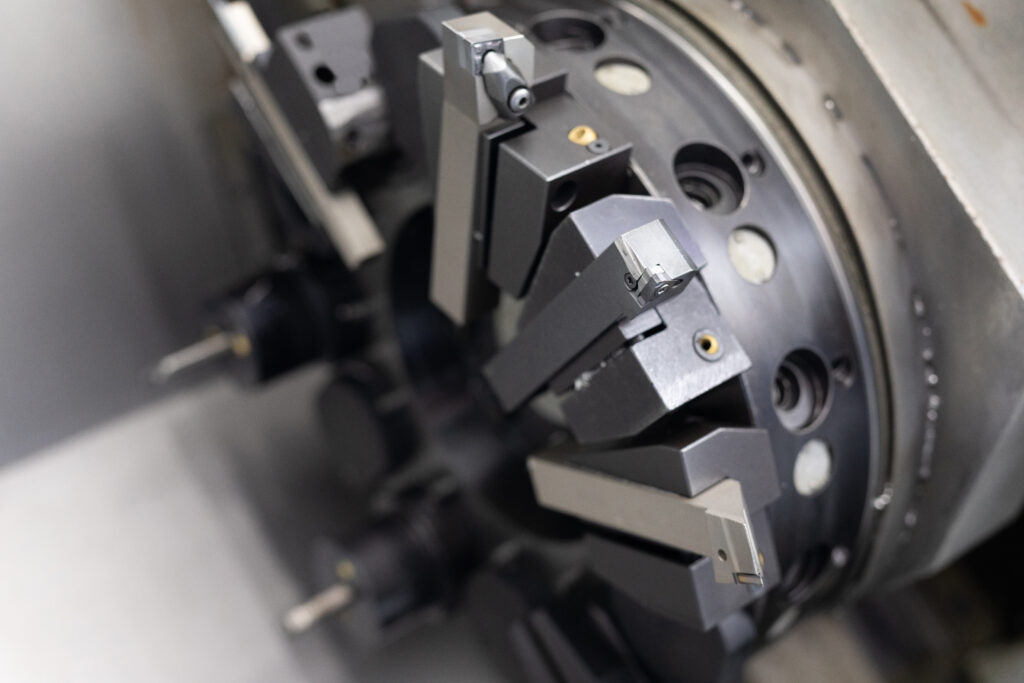

| Turning / Lathe | Shafts, rings, threaded parts | Assembly-ready cylindrical components |

| Hybrid Mill-Turn | Milling + turning on same setup | Reduces tolerance drift between ops |

| CNC Metal Cutting Machine Cells | Sheet & block removal for volume | Pre-production supply / bridge manufacturing |

Operations We Run

- Surfacing, pocketing, chamfering

- Drilling, tapping & threading to spec

- Edge prep & burr management

- Surface finishing: bead-blast, brushing, anodizing (via partners)

These setups enable us to produce both prototypes and recurring supply for export.

This is where a cnc metal milling machine differs from a generic workshop — the output is consistent, repeatable, and assembly-ready.

Operational Fit — When CNC Is the Right Choice

- You need production-quality prototypes

- You need 10–1,000 unit bridge manufacturing

- Your assembly tolerance stack-up needs verification

- You plan to move to casting or molding later

Our cnc metal cutting machine workflows handle both geometric complexity and finish-critical requirements, making CNC the bridge to eventual casting or tooling if volume justifies it.

Need to confirm manufacturability before ordering?

We’ll check geometry, tolerance feasibility & machining strategy.

Industries & Applications Using CNC Metal Machining

CNC metal machining isn’t just for prototypes — it’s used across industries where tolerance, load, thermal behavior, and assembly fit matter more than speed or volume. Teams use a cnc machine for metal when structural integrity can’t be compromised and the part must be ready for field use or certification.

Who Buys CNC Metal Machined Parts & Why

| Industry | Why CNC Metal Works | Common Ordered Parts |

|---|---|---|

| Automotive & EV | Lightweight + strength balance, jigs for assembly lines | Brackets, housings, test rigs, powertrain fixtures |

| Aerospace & Defense | Weight-to-strength ratio, critical geometry | Titanium fittings, 7075 brackets, mounting blocks |

| Medical & Pharma | Hygiene-compliant, corrosion resistant, sterilisable | 316L contact components, valve blocks, trays |

| Robotics & Automation | Repeatability under motion & load | Gear housings, actuator plates, shafts, pulleys |

| Industrial Machinery | Durability + maintainability | Custom tooling, steel fixtures, mild steel machine parts |

| Electronics & Hardware | Heat dissipation + precise enclosures | Aluminum housings, heat sinks, connector bodies |

In every one of these verticals, CNC machining is chosen before casting or forging because design changes are expected during field testing.

Why These Sectors Don’t Start with Tooling

- Tooling cost can lock in design too early

- Molded/cast parts can’t be easily modified

- EV, aerospace & pharma require validation stages

- Real-world stress testing needs machined metal first

CNC is the engineering truth stage — not the experiment stage.

Building for automotive, aerospace, robotics, or medical?

We’ll validate tolerance, material, and operating environment before machining.

Tolerances, QA & Surface Finish Standards for Metal Machining

Metals demand tolerance control because they are installed into real mechanical systems, not demos. If a shaft is off by 0.02mm, it won’t seat. If a thread isn’t aligned, torque fails. CNC machining is chosen because it protects those margins.

Typical Tolerance Ranges

| Material | General Tolerance Range |

|---|---|

| Aluminum (6061/7075) | ±0.01 mm – ±0.03 mm |

| Stainless Steel (304/316L) | ±0.01 mm – ±0.02 mm |

| Mild / Carbon Steel | ±0.02 mm – ±0.05 mm |

| Brass / Copper | ±0.01 mm – ±0.03 mm |

| Titanium | ±0.01 mm – ±0.02 mm (if thermal stability controlled) |

If tolerance affects assembly stack-up, we request a drawing. If you don’t have one, we help create it.

Quality Inspection Workflow

- DFM Check – Identifies risk points before machining

- Critical Dimension Mapping – Flags tolerances that matter for assembly

- Machining Strategy Selection – Toolpath, coolant, clamping logic

- CMM / Vernier / Height Gauge Inspection

- Batch Repeatability Assurance – Stability measured part-to-part

With the right setup, a cnc metal milling machine delivers repeatability that fabrication cannot.

Surface Finishes & Post-Process Options

- Machined finish (standard)

- Brushed finish for housings

- Bead blasting for texture + uniformity

- Anodizing (Aluminum) via finishing partners

- Ra requirement specified per surface if needed

Finish choices are not aesthetic — they’re functional. They decide corrosion resistance, upgrade compatibility, and final market readiness.

We use calibrated setups for cnc machines for metal to achieve finish and dimensional targets suitable for both prototype and production supply.

Tolerance-critical part?

Share your 2D drawing + STEP file for a no-risk tolerance validation.

CNC vs Casting vs Metal 3D Printing vs Fabrication (Decision Matrix)

Engineering teams don’t choose a process based on capability alone — they choose based on stage, volume, tolerance, and financial risk. CNC machining is not always the cheapest, but it’s the most truthful method for dimensional validation before scale.

Manufacturing Method Comparison

| Material | General Tolerance Range |

|---|---|

| Aluminum (6061/7075) | ±0.01 mm – ±0.03 mm |

| Stainless Steel (304/316L) | ±0.01 mm – ±0.02 mm |

| Mild / Carbon Steel | ±0.02 mm – ±0.05 mm |

| Brass / Copper | ±0.01 mm – ±0.03 mm |

| Titanium | ±0.01 mm – ±0.02 mm (if thermal stability controlled) |

When CNC is the Smartest First Step

- Design is not frozen yet

- Regulatory testing is pending

- Fitment between mating parts needs real-world confirmation

- Tooling investment isn’t justified

- Final assembly tolerance is unknown

When You Should Shift Away from CNC

- Annual volume > 10,000 units

- Surface finish requirements need mold-grade consistency

- Material cost is too high to scrap for iteration

- Geometry favors near-net-shape casting

A cnc metal cutting machine is chosen when accuracy matters more than volume, and a cnc machine for metal becomes the stabilizer before tooling.

RFQ Requirements, Pricing Logic & Conversion Paths

A clear RFQ reduces back-and-forth, saves engineering time, and prevents incorrect assumptions that inflate cost. To quote metal CNC machining correctly, we need alignment on intent, not just a CAD file.

What Manufyn Needs for a Realistic Quote

| Input | Why It Matters |

|---|---|

| 3D CAD (STEP/IGES/SLDPRT) | Generates toolpath, identifies workholding strategy |

| 2D Drawing (if tolerance critical) | Protects GD&T and assembly-critical dimensions |

| Material & Grade | Changes tool wear, coolant choice, cycle time |

| Quantity Range | Decides whether CNC or pre-cast strategy fits |

| Finish & Ra Requirement | Impacts post-processing & pricing |

| End-Use Environment | Decides material suitability (marine, pharma, high heat) |

Pricing Logic Formula

Pricing is influenced by:

- Material cost (Aluminum vs SS vs Brass vs Titanium)

- Machine time (3-axis vs 4-axis vs 5-axis)

- Tool wear (higher in stainless/titanium → higher cost)

- Tolerance band (tight tolerance increases operations)

- Surface finish & post-processing

- Annual volume / reorder expectation

Quick cost reality checks:

- Prototype: Higher cost per part → lowest financial risk

- Bridge batches: Moderate cost → best data for scaling

- Production: Lowest cost → only if design is frozen

That’s why CNC is not “expensive” — it’s risk protection before mass production.

Ready for pricing? Prototype or production — we’ll quote both paths.

Scaling Strategy — CNC → Casting / Die Casting / MIM / Production

CNC machining is not the final step for every product — it’s the decision-proofing stage before tooling. Once dimensions stabilize and volume justifies investment, the part transitions from machining to a mass-production process.

How the Transition Works

| Stage | Method Used | Why |

|---|---|---|

| Prototype Validation | CNC Machining | Confirms geometry & tolerance before investment |

| Bridge Manufacturing (25–2,000 units) | CNC Machining | Supports sales pilots, field tests, certifications |

| Scale / Cost Optimization | Casting / Die Cast / MIM | Unit economics justify tooling |

| Repeatable Supply | Molding + Machine Finish | Final cycle time reduction + surface fidelity |

This prevents the most expensive manufacturing mistake: Paying for tooling before the design is proven.

When to Stay With CNC

- Forecast below 10,000 units annually

- Design changes expected post-field testing

- Tolerances are still being finalized

- Short-run production with immediate deadlines

When to Move Beyond CNC

- Unit price must drop for commercial release

- Parts are ready for long-term supply planning

- Design is frozen and approved for certification

A cnc machine for metal validates performance. A casting tool scales it. The two are not competitors — they are sequential steps in a manufacturing strategy.

Request a CNC Machining Quote for Metals

Upload CAD → get feasibility → tolerance review → pricing for prototype & production.

Frequently Asked Questions

What metals can be machined using a CNC machine for metal?

Engineering metals commonly machined include Aluminum (6061/7075), Stainless Steel (304/316L), Mild Steel, Brass, Copper, and Titanium. These materials perform well on cnc machines for metal due to stability, strength, and tolerance control.

Is CNC machining better than casting or metal 3D printing for prototypes?

Yes. For prototypes or low-volume batches, CNC machining is preferred over casting or metal 3D printing because a cnc metal milling machine offers tighter tolerance, better surface finish, and assembly-ready fit before tooling investment.

How accurate are metal CNC machines for production parts?

Most modern metal cnc machines achieve tolerances between ±0.01mm and ±0.03mm depending on the metal grade, geometry complexity, and finishing requirements. Stainless steel and titanium may require tighter thermal management for accuracy.

What information is needed to request a CNC machining quote for metals?

To generate pricing, suppliers usually need a 3D CAD file (STEP/IGES), 2D drawing with tolerances, material grade, quantity range, and finish requirements. This helps define toolpaths, cycle time, and strategy for a cnc metal cutting machine.

Which metals are best for lightweight strength in CNC machining?

Aluminum 6061 and 7075 are the most common lightweight options. They provide excellent machinability and are ideal for enclosures, brackets, and aerospace components produced on a cnc machine for metal when weight vs strength matters.

Can CNC machining produce assembly-ready, threaded, and finished parts?

Yes. A cnc metal milling machine can drill, tap, countersink, and surface-finish parts to make them assembly-ready. Additional options include bead blasting, brushing, and anodizing for aluminum components.

What batch sizes are ideal for CNC machining before moving to casting or die-casting?

CNC machining is ideal for prototypes, bridge manufacturing, and production runs from 10 to 2,000 units. Once design is stable and volume demand increases, production can shift to casting or molding; CNC becomes the validation stage.