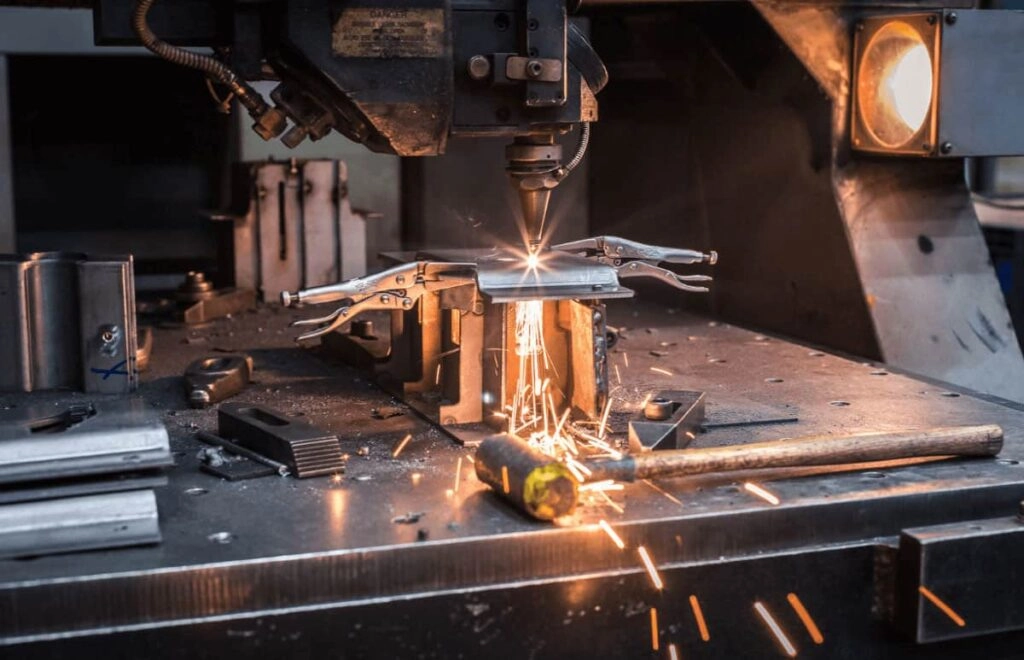

Prototype Manufacturing Services for Rapid Product Development

Prototype manufacturing is the bridge between innovation and execution. At Manufyn, we specialize in manufacturing prototypes that not only bring your vision to life but also ensure form, fit, and functionality from the outset. As a leading manufacturing company, we support businesses through every phase.