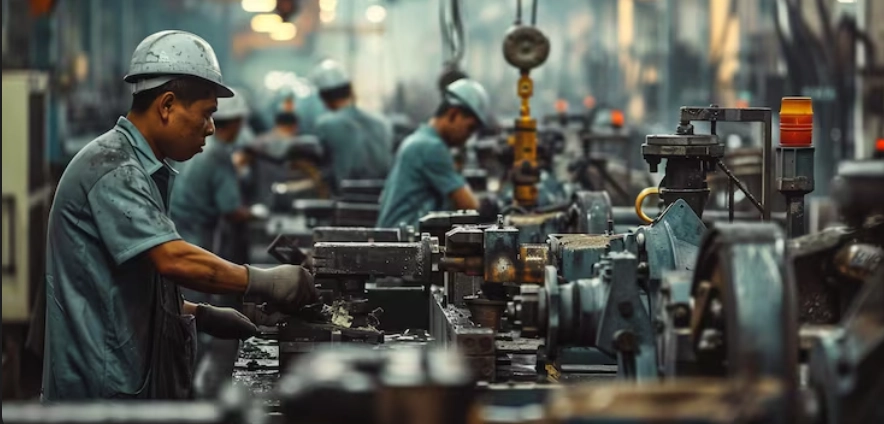

Mass Manufacturing Services for Scalable High-Volume Output

Delivering Scalable, High-Volume Solutions with Precision

At Manufyn, we specialize in mass manufacturing solutions that help businesses scale efficiently, without compromising on quality. Whether you’re launching a consumer product or ramping up industrial component production, our advanced systems and global-ready processes are built to deliver consistent, repeatable results—at scale.

As a trusted partner to startups and large enterprises alike, we bridge the gap between prototyping and mass production through robust supply chains, intelligent automation, and multi-material capabilities.