Batch Production Services for Flexible, Mid-Volume Manufacturing

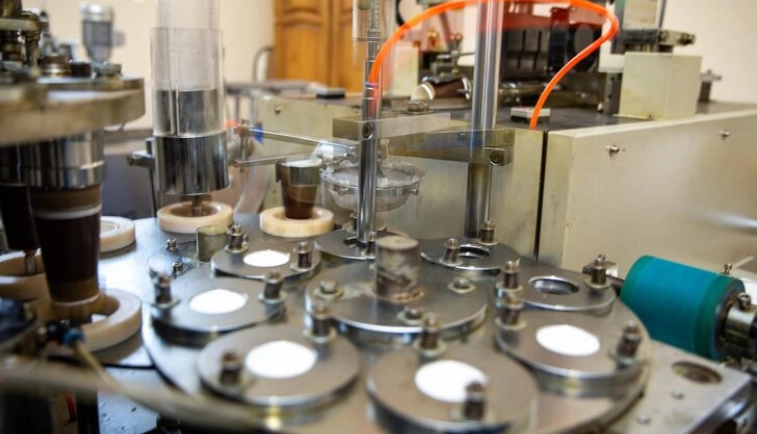

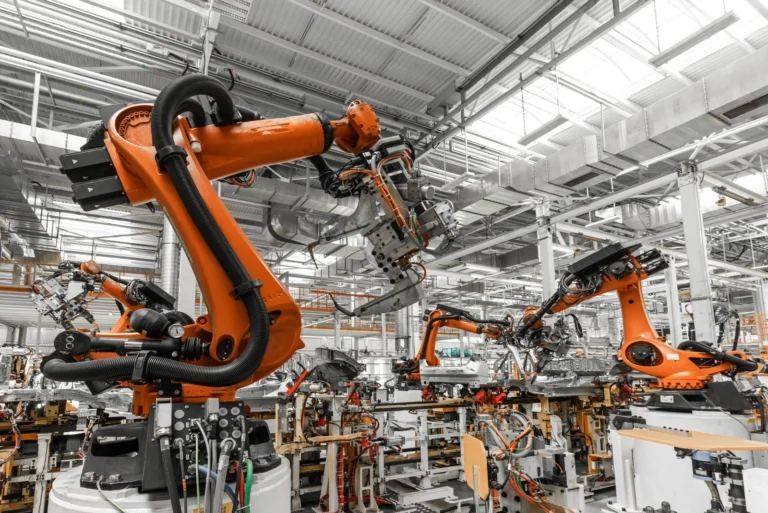

We specialize in batch production, processing products tailored to your volumes, timelines, and customization needs. Our India-based manufacturing ecosystem enables scalable, cost-effective, and quality-driven batch processing manufacturing across a wide range of industries — from automotive to electronics.

Examples of batch production include scaling up after prototyping or producing limited-edition runs; our batch manufacturing capabilities deliver efficiency, consistency, and control.