Computer-Aided Design CAM Manufacturing Services for Precision Machining Workflows

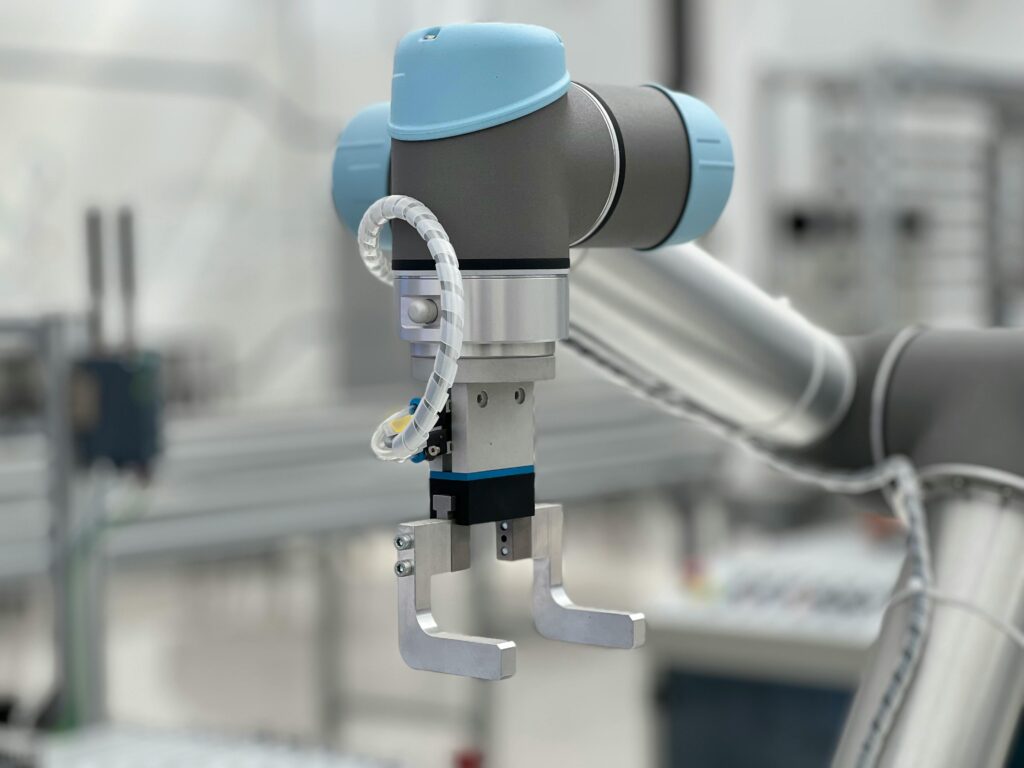

At Manufyn, we provide integrated computer-aided design and manufacturing (CAM) services that streamline your product development and production workflows. From optimized toolpaths to precision simulations, our CAM manufacturing capabilities help bridge the gap between digital design and real-world manufacturing.

Whether you’re producing custom components or scaling for batch manufacturing, our computer aided design manufacturing services are built for speed, accuracy, and industrial compatibility.