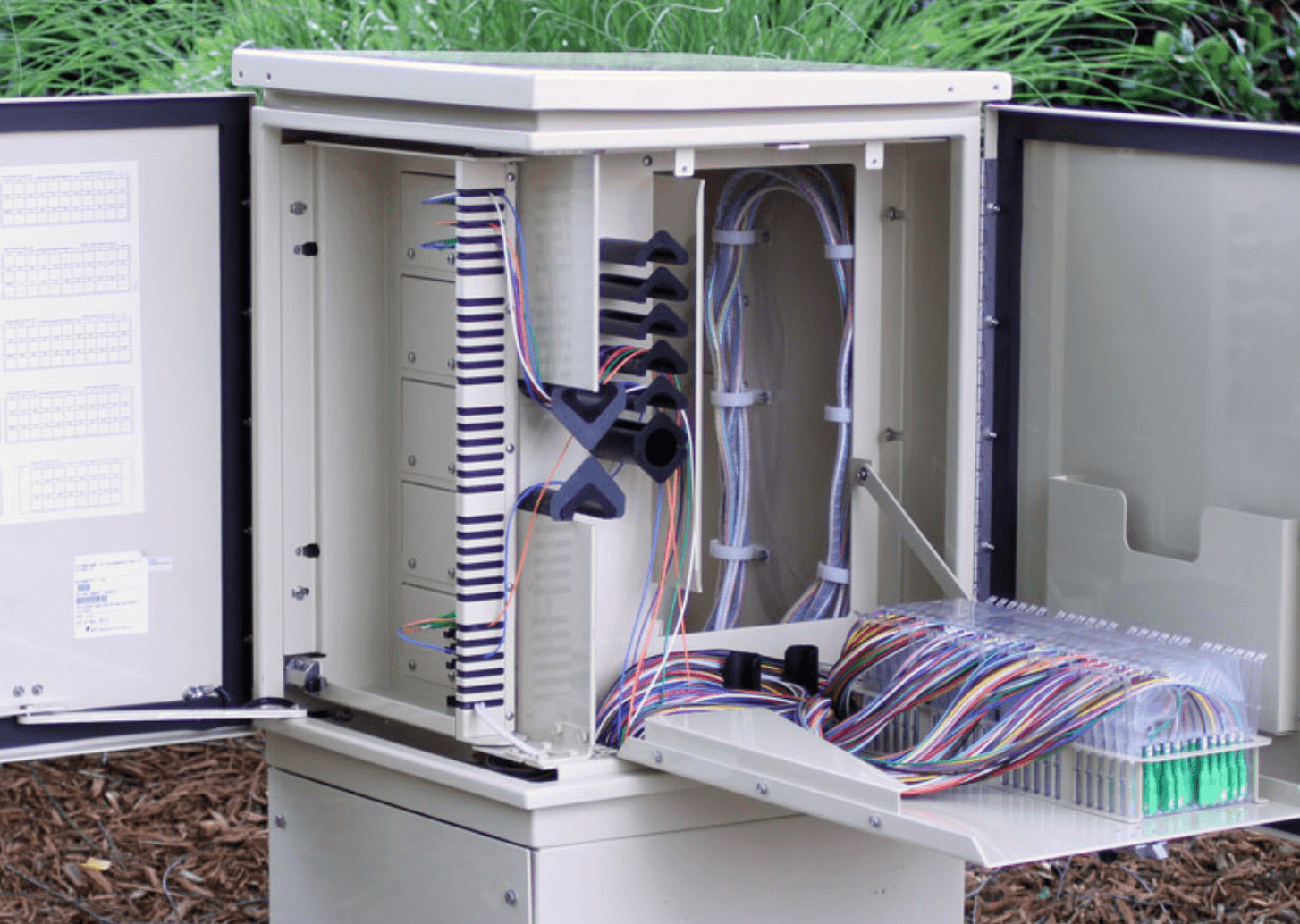

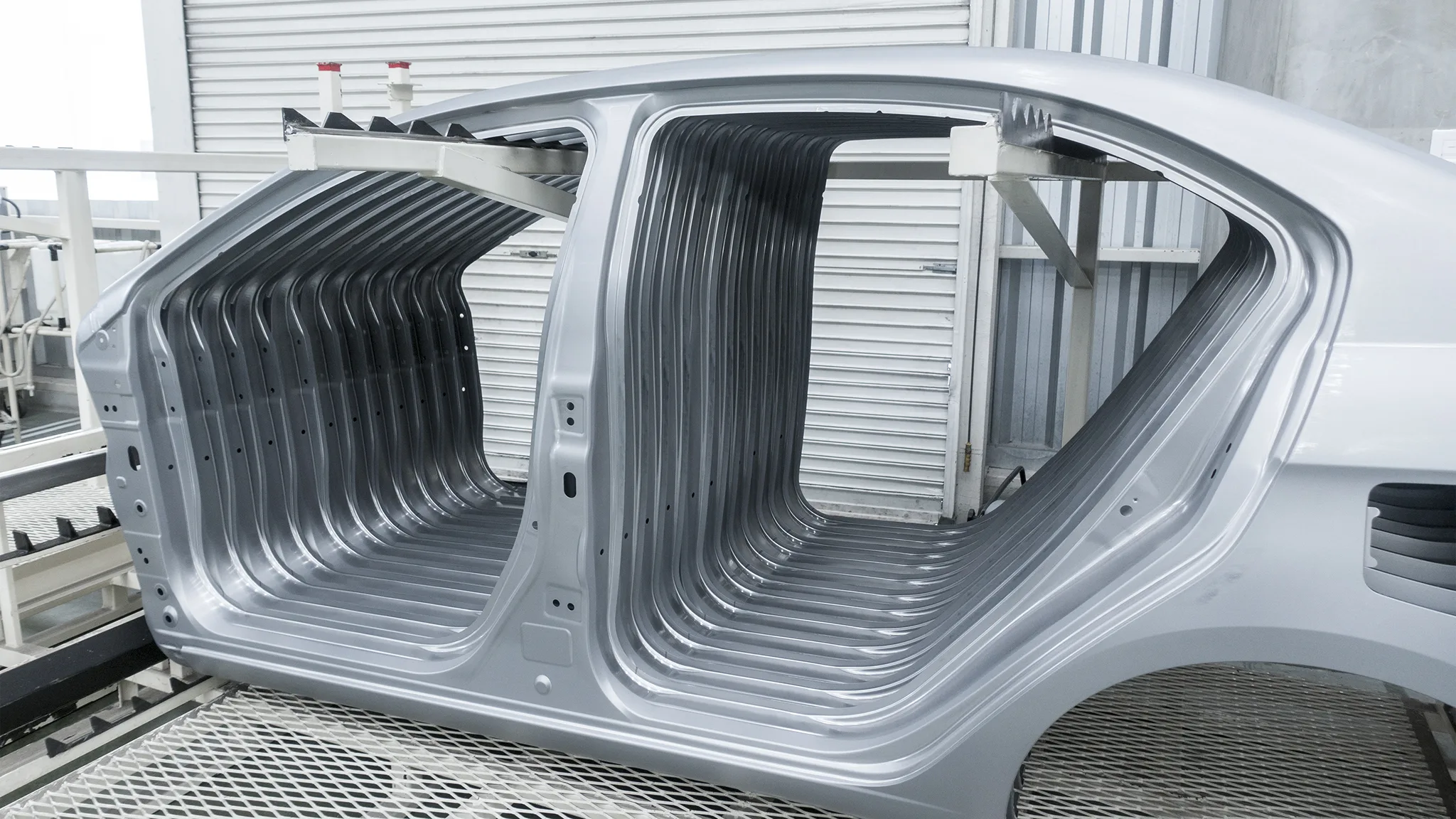

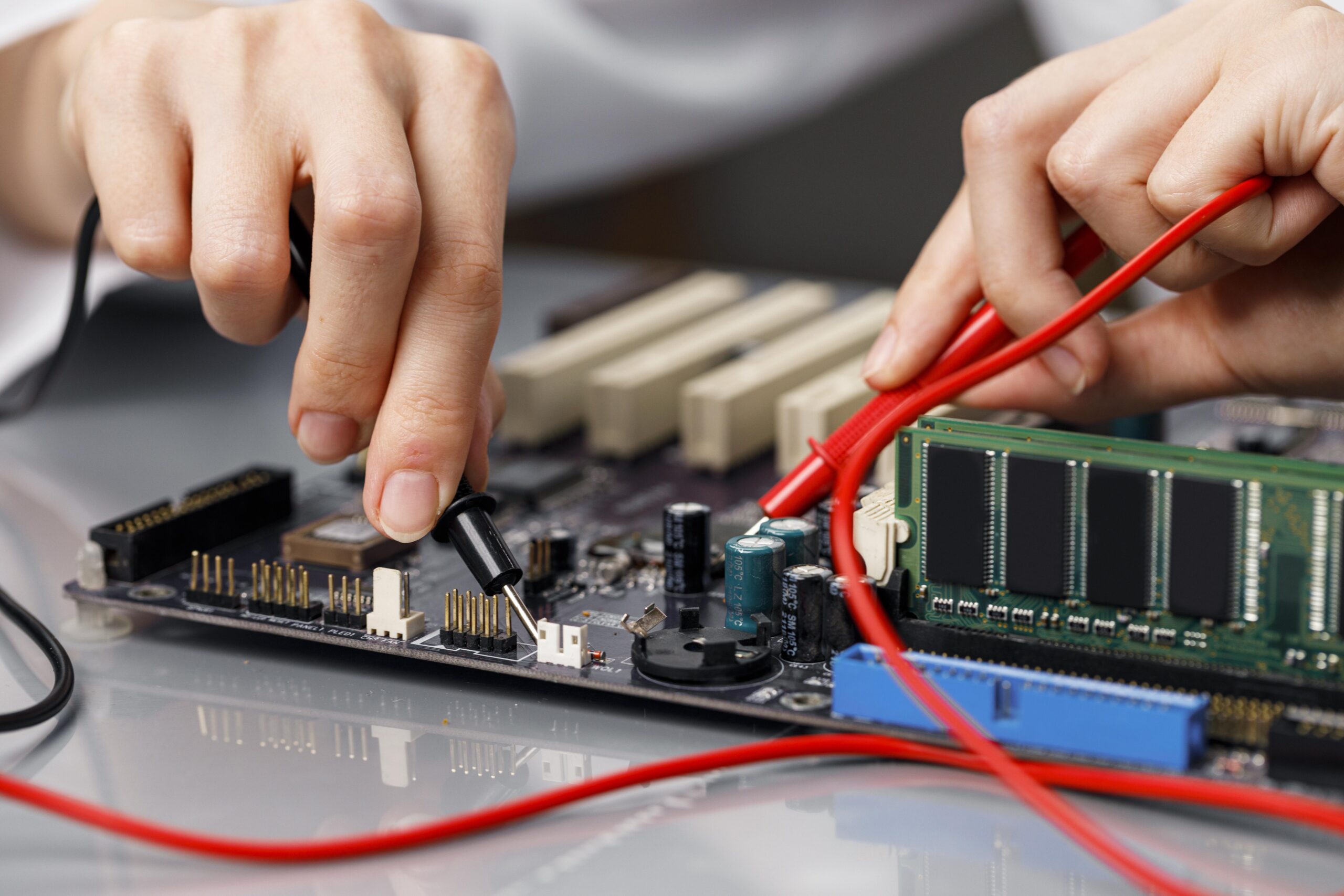

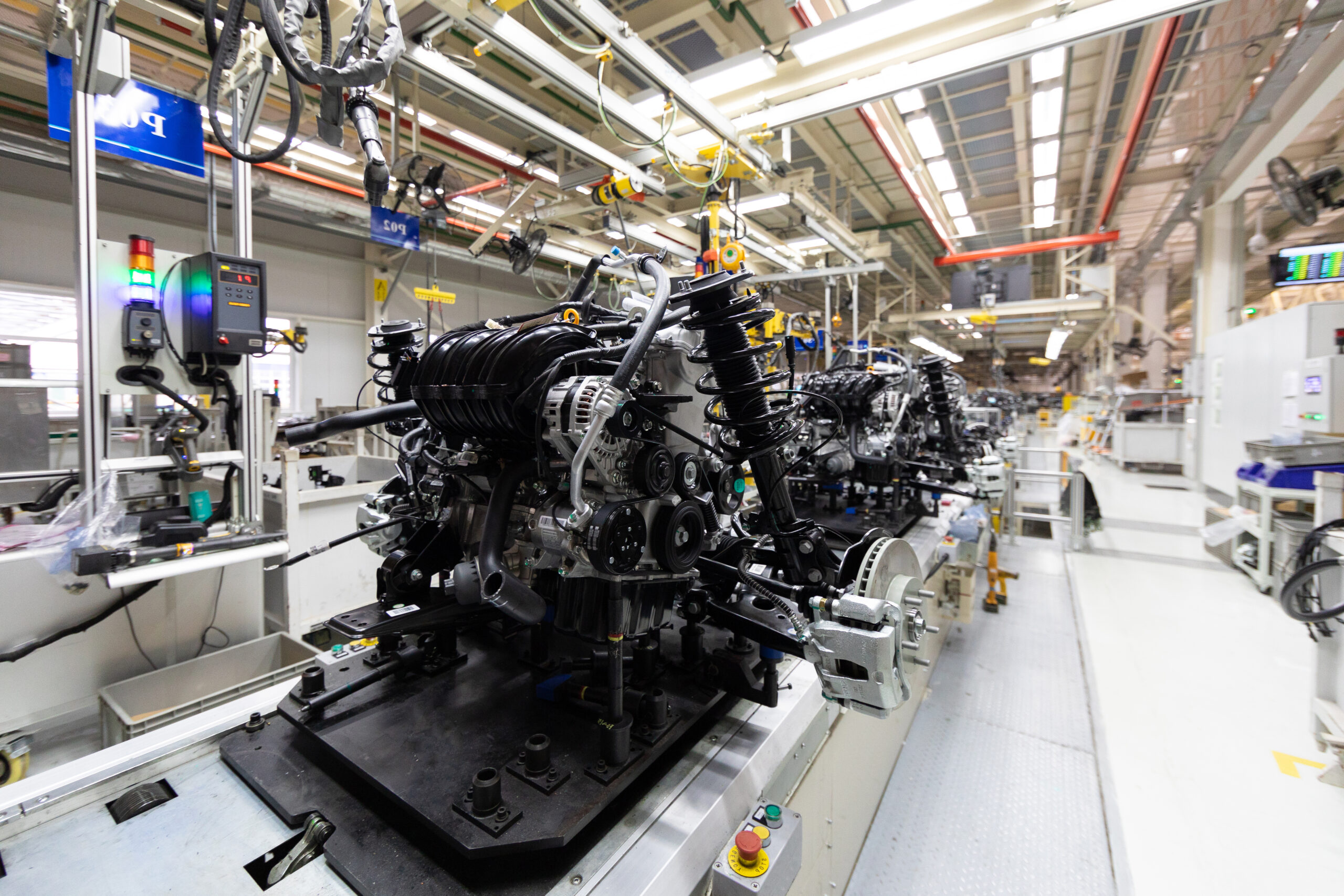

Sheet Metal Assembly Services for Ready-to-Use Components

Seamless Assembly of Precision-Fabricated Sheet Metal Components

Manufyn provides high-precision sheet metal assembly services that ensure your parts not only fit — they function with strength, accuracy, and efficiency. From simple brackets to complex enclosures and structural frames, we handle the complete assembly of sheet metal parts using advanced techniques and integration methods tailored to your product and industry needs.