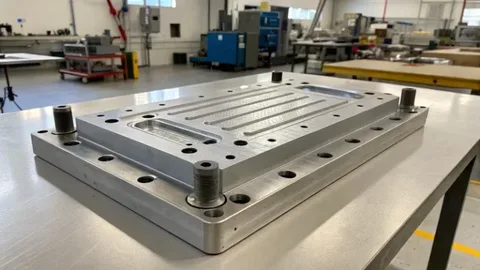

Overmolding Services for Enhanced Grip and Component Strength

Engineered Overmolding Solutions for High-Performance Multi-Material Parts

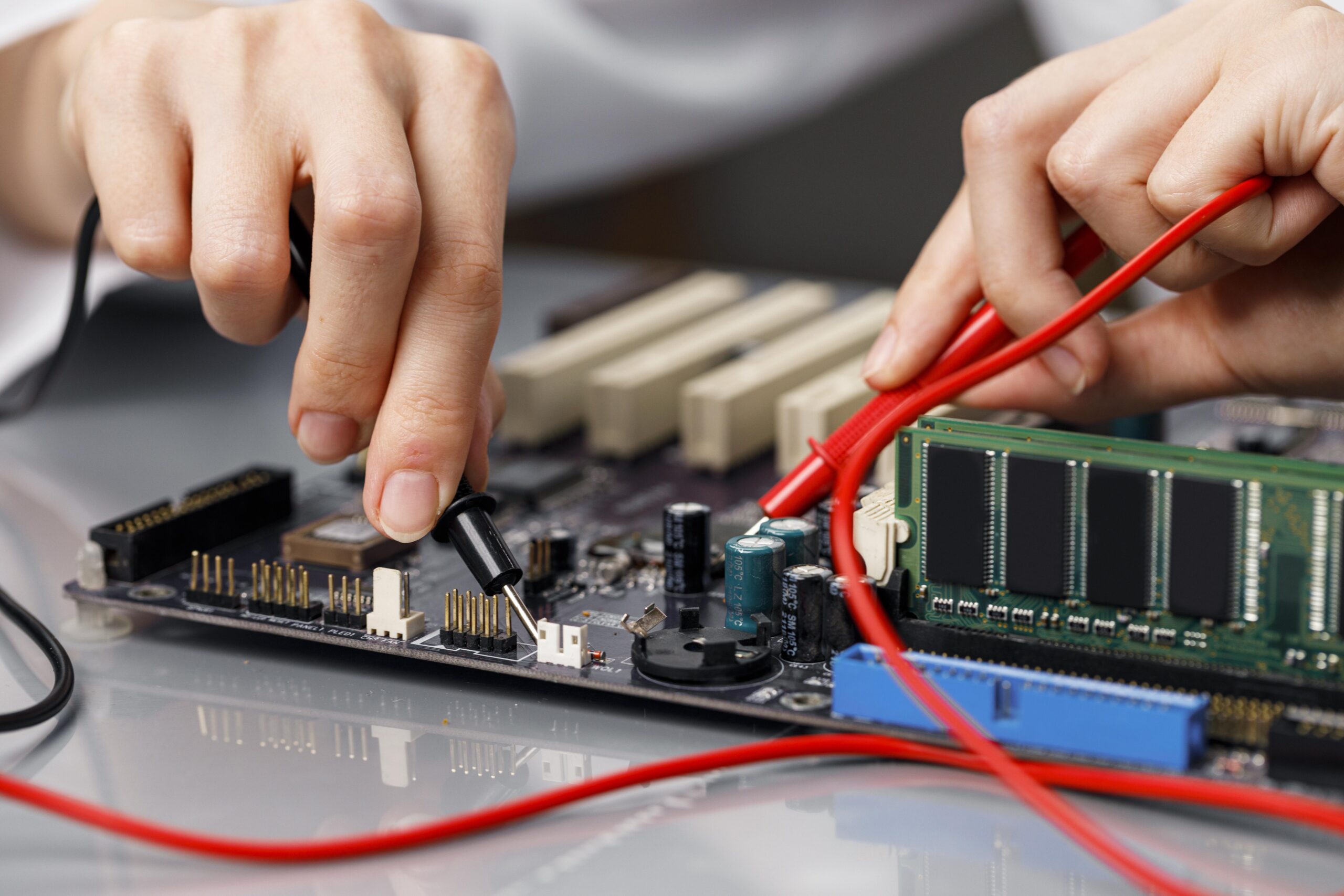

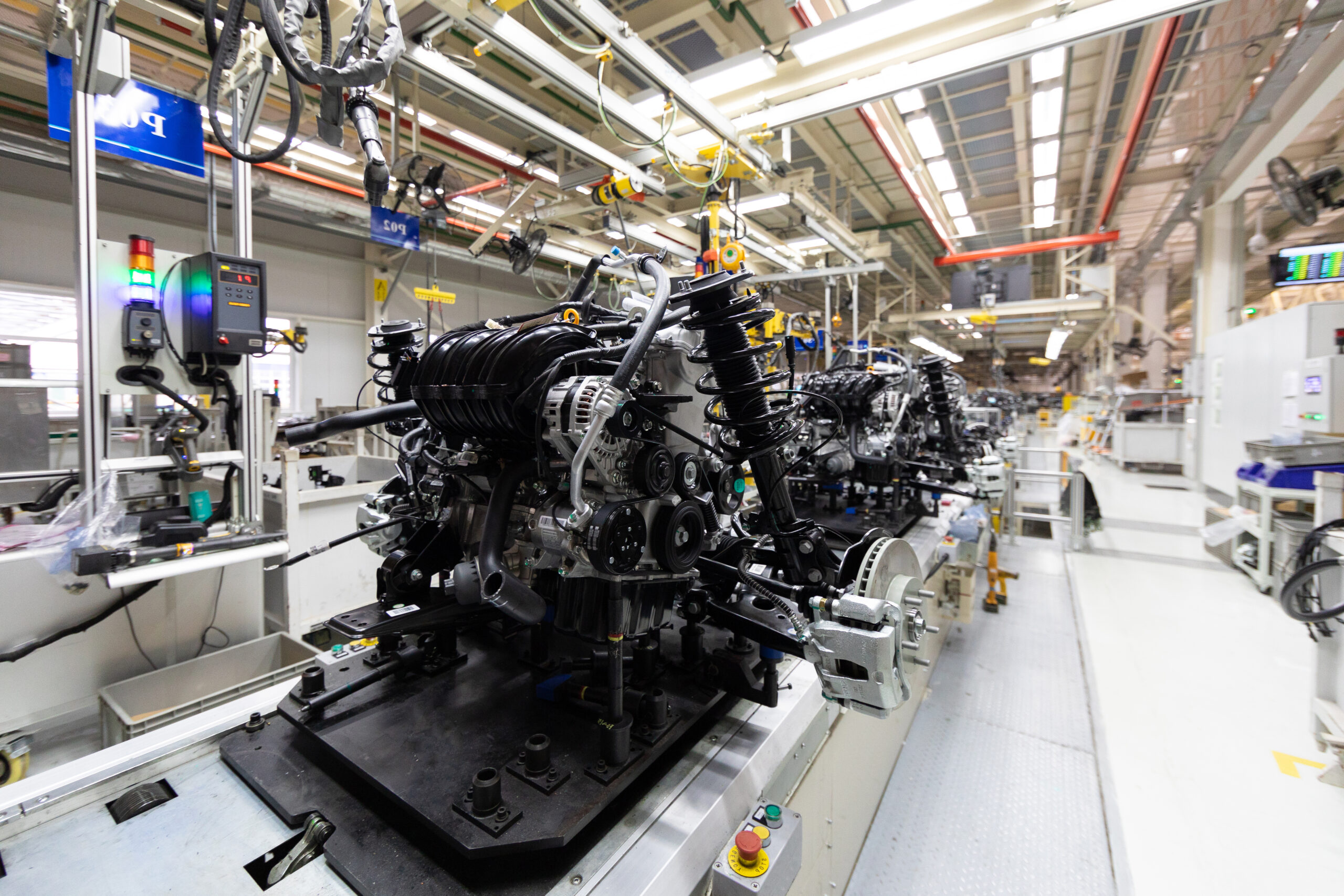

Manufyn delivers precision-engineered overmolding services that enhance both the performance and appearance of complex plastic and rubber components. By combining two or more materials into a single, bonded structure, overmolding enables improved ergonomics, durability, vibration resistance, and aesthetic finish