Extrusion Molding Services for Flexible Plastic Profiles

High-Precision Extrusion Molding for Custom Plastic Profiles and Tubular Components

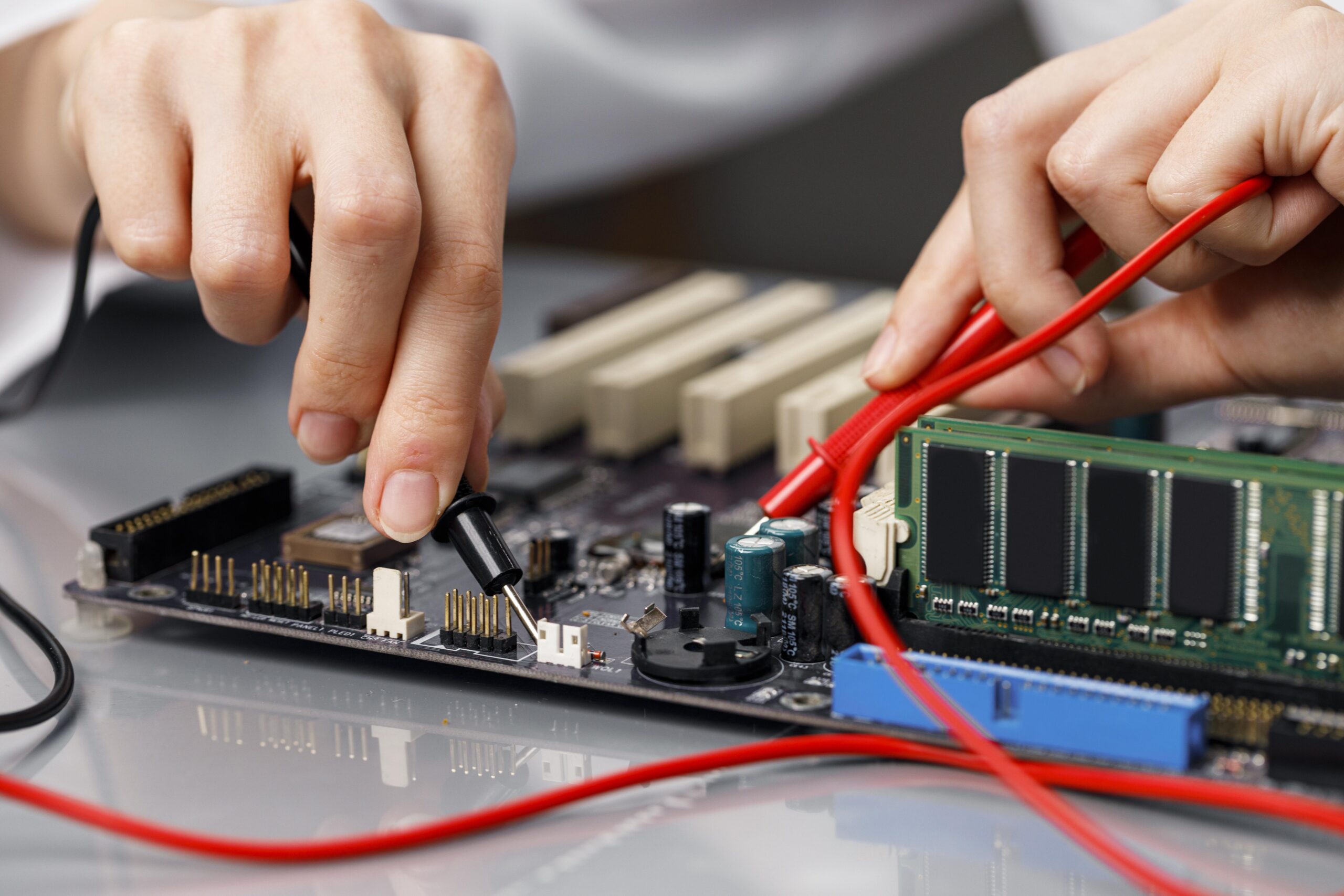

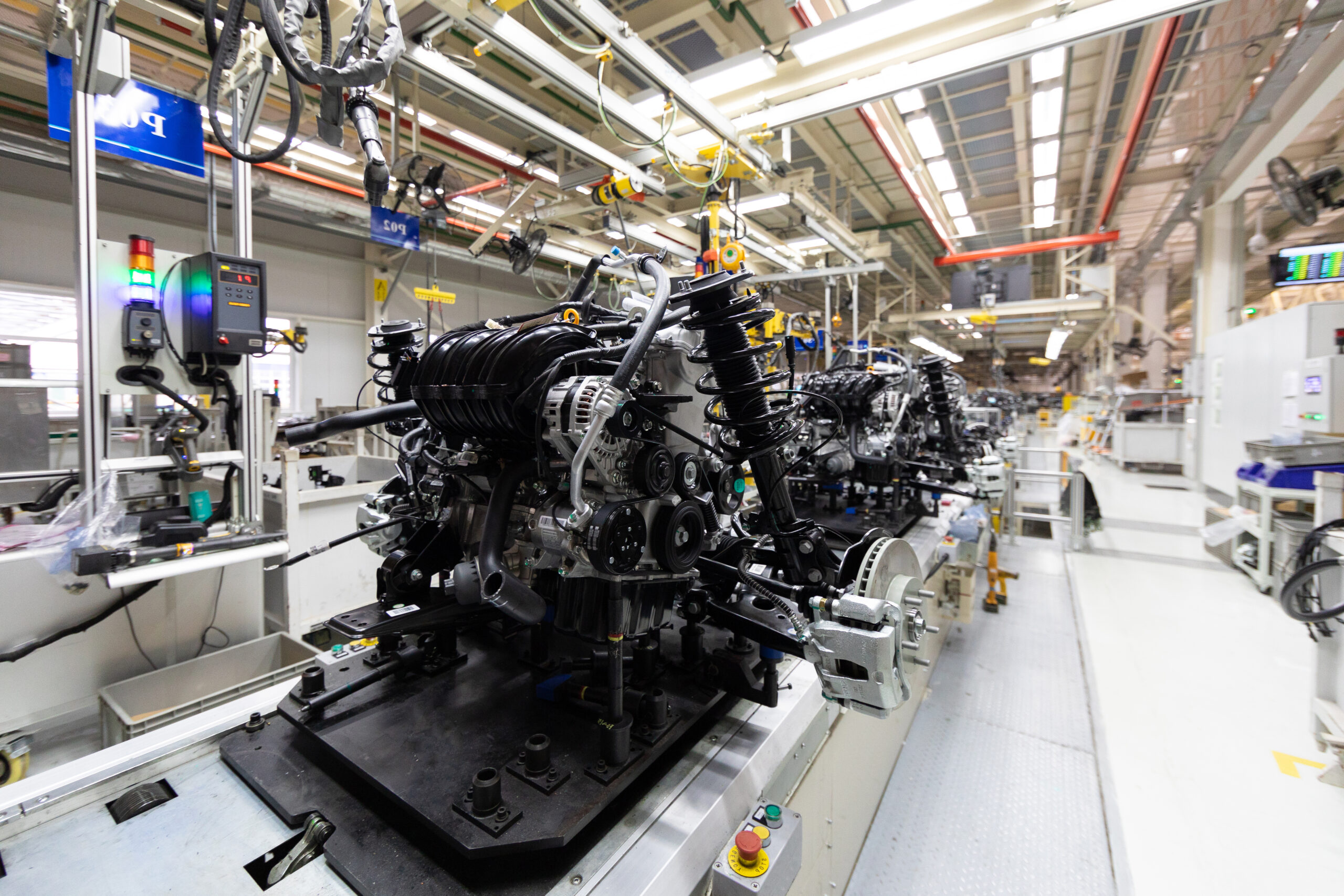

At Manufyn, our extrusion molding services are tailored for producing continuous plastic parts with uniform cross-sections, such as tubes, pipes, profiles, rods, and sheets. By combining precision dies, high-performance materials, and end-to-end quality control, we deliver scalable solutions for applications in automotive, medical, construction, electrical, and consumer industries.