Blow Molding Services for Lightweight, Custom Plastic Products

Precision Blow Molding for Hollow, Lightweight, and Durable Plastic Products

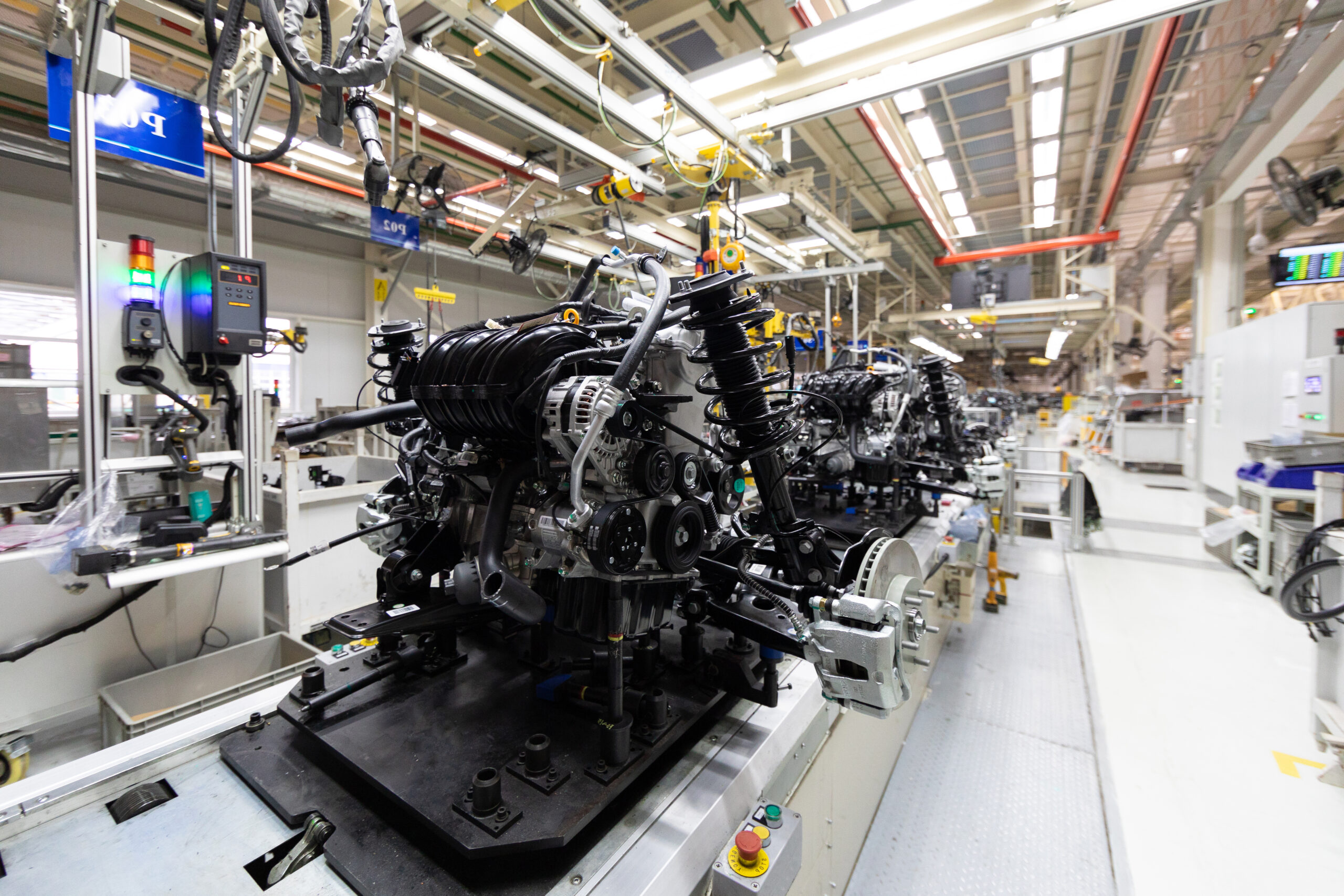

Manufyn provides specialized blow molding services tailored for the efficient production of high-quality, hollow plastic parts. With advanced tooling, process control, and material handling, we manufacture containers, bottles, ducts, tanks, and packaging components that meet industry standards across sectors such as FMCG, automotive, healthcare, and industrial packaging.