Plastic and Rubber Manufacturers for Durable Custom Components

Custom-Molded, Precision-Engineered Components for Every Industry

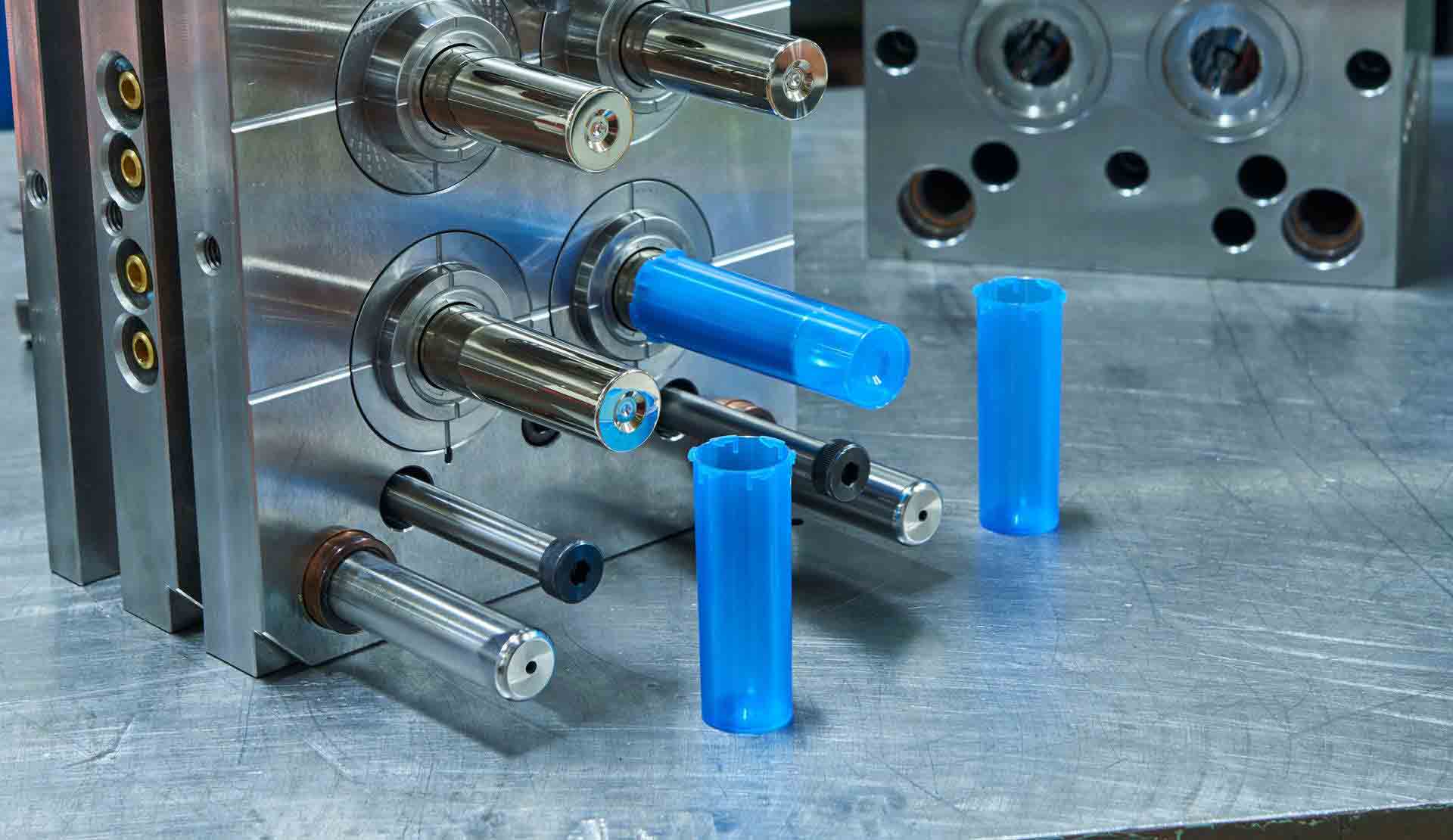

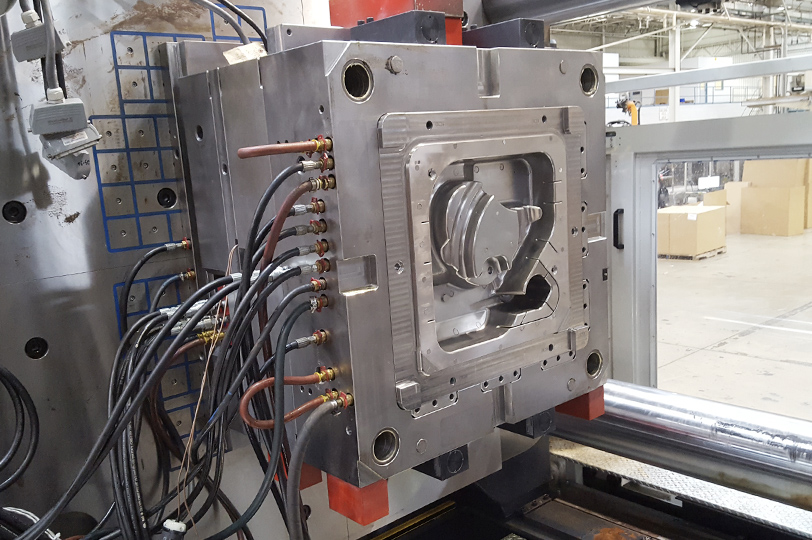

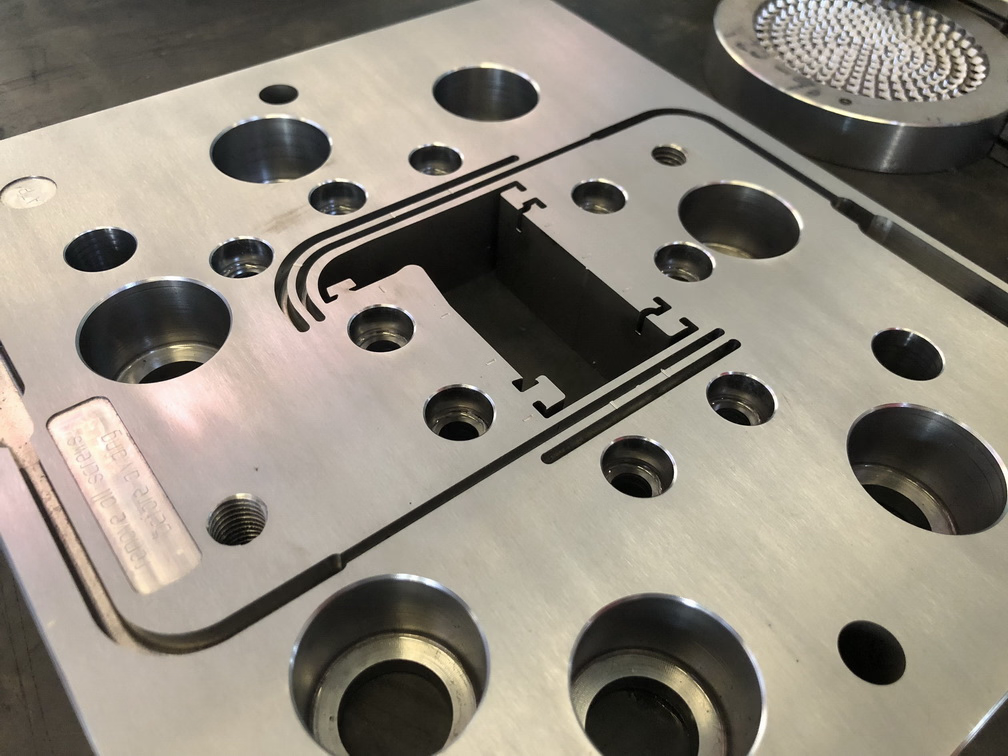

At Manufyn, our Rubber and Plastic Manufacturing capabilities are built to meet diverse industrial demands across automotive, electronics, healthcare, consumer goods, and heavy engineering. Whether you’re looking for high-volume plastic injection molding or specialized rubber-to-metal bonded parts, we bring material expertise, advanced tooling, and scalable manufacturing solutions under one roof.