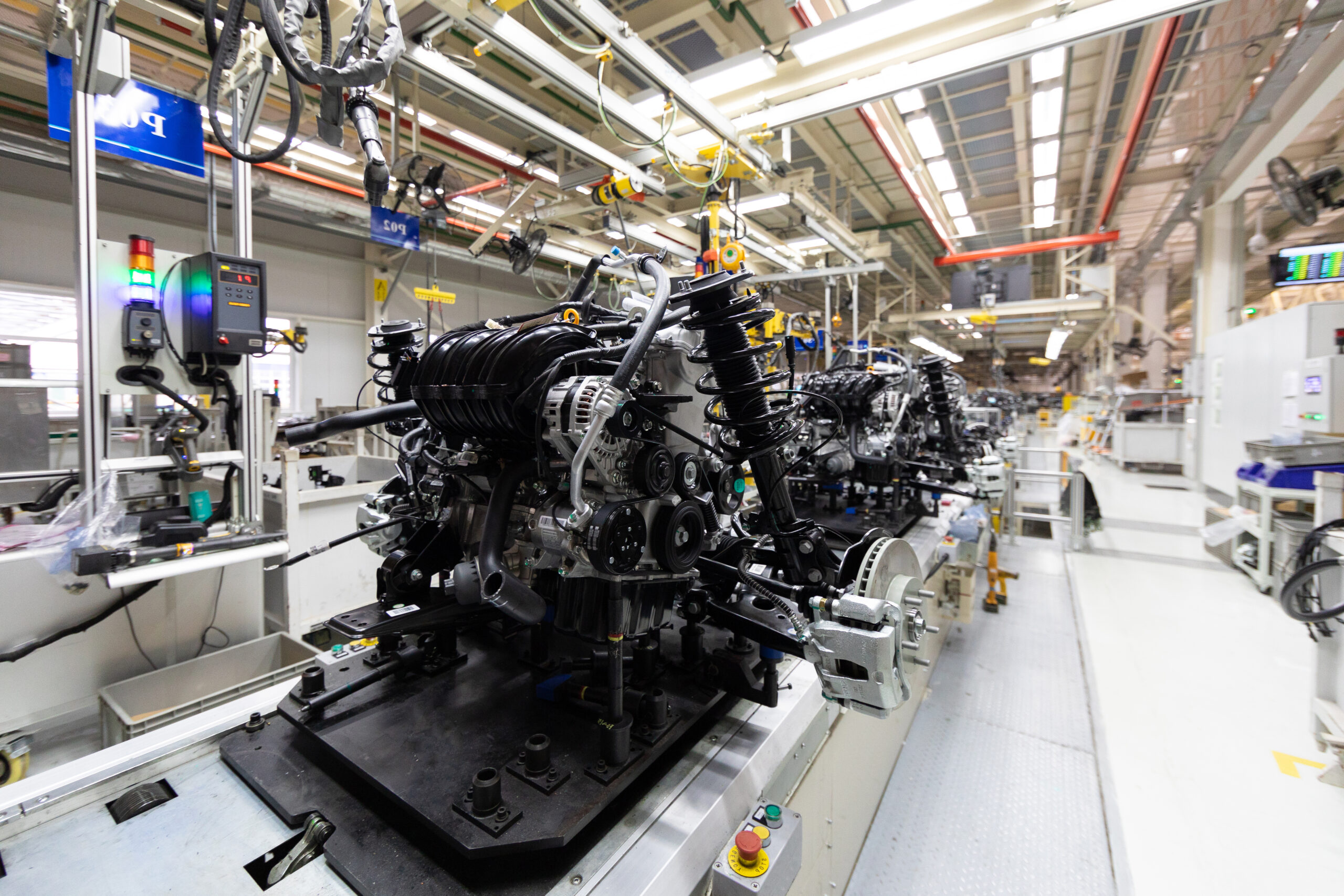

Closed Die Forging Services for Complex, High-Volume Components

High-Precision Forged Parts for Critical Applications

Manufyn offers advanced closed die forging services designed for high-volume, repeatable production of precision metal components. Also known as impression die forging, this process delivers net or near-net shaped parts with exceptional mechanical properties and surface finish.