1M+

Parts

Delivered

100+

Global

Clients

500+

Vendors

Onboard

25+

Industries

Served

What is Forging?

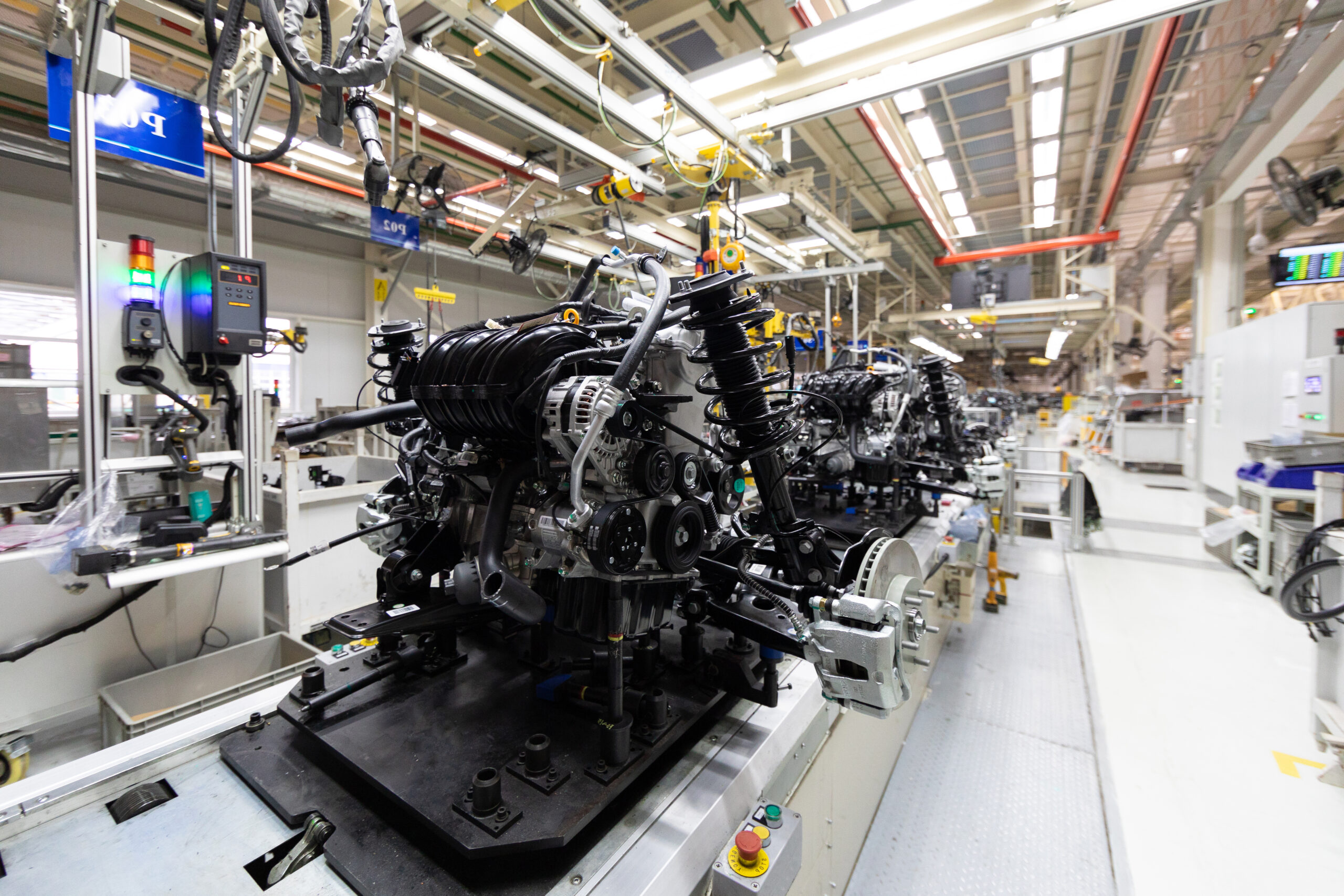

Forging is a precision manufacturing process that shapes metal using intense compressive forces, typically applied through hammering, pressing, or rolling. One of the oldest techniques in metalworking, forging is still one of the most reliable ways to produce durable, high-strength components used in aerospace, automotive, defense, and heavy industrial applications.

The Forging Process: Step-by-Step

The forging process relies on thermal and mechanical energy to mold metal into the desired shape. Unlike casting, forging enhances the grain structure of the metal, significantly improving its toughness and fatigue resistance.

Heating

The metal is heated to a precise temperature to make it malleable without compromising structural integrity.

Shaping

Using forging machines such as hammers, hydraulic presses, or rollers, the metal is shaped under high pressure into the desired geometry.

Cooling & Finishing

Once shaped, the part is cooled and undergoes heat treatment, trimming, or surface finishing to enhance performance and appearance.

Types of Forging Techniques

We offer a variety of forging processes tailored to your project’s volume, complexity, and material needs:

Open-Die Forging

Ideal for large, simple components. Offers flexibility for low to medium volume production.

Closed-Die Forging

Best for precision parts with tight tolerances and repeatability in large volumes.

Upset Forging

Used for increasing the cross-sectional area of a portion of the part, such as bolts and fasteners.

Hot and Cold Forging

Depending on your application and material, we select the appropriate method to balance formability and finish.

Why Manufyn is Your Ideal Forging Partner

Manufyn is a trusted name in the forging industry, offering state-of-the-art tools and equipment for high-quality, custom-made parts. Our forging services ensure that every part meets the highest standards of strength, durability, and precision, making us the ideal partner for your next project.

Expert Forging Technicians

Ideal for large, simple components. Offers flexibility for low to medium volume production.

Advanced Forging Machines

Our forging setup includes high-tonnage hammers, mechanical presses, and automated systems for consistency and scalability.

Custom Metal Forging

Whether you need a one-off prototype or full-scale production, we offer custom molds, die tooling, and full DFM support.

Material Versatility

We forge a wide range of forging materials, including stainless steel, titanium, aluminum, and specialty alloys.

Casting vs Forging: Which One is Right for You?

Feature

Forging

Casting

Strength & Durability

High (grain structure aligned)

Moderate (depends on design & metal)

Material Integrity

Excellent

Good with risk of porosity

Precision

High (especially in closed-die forging)

High with investment casting

Cost-Effectiveness

Better for high-performance applications

Better for complex, low-stress parts

Ideal For

Aerospace, Automotive, Machinery

Art, Architecture, Complex Cast Shapes

Understanding reflow soldering vs wave soldering helps in selecting the right process:

Forging Applications Across Industries

Trust Manufyn for Premium Forging Solutions

When it comes to metal forging, strength, quality, and consistency are non-negotiable. At Manufyn, we combine custom forging capabilities with next-gen technology to deliver components that power your most ambitious projects.

Book Free Consultation

FAQs on Forging

The custom industry involves manufacturing parts by applying compressive forces to shape metal, ensuring high strength and durability.

Forging involves shaping solid metal using pressure, while casting involves pouring molten metal into a mold to form parts.

Forging requires specialized tools such as hammers, presses, and die tools to shape the metal.

Manufyn provides high-quality, custom forging solutions using advanced equipment and expert technicians to ensure superior products.

Our precision forging processes ensure tight tolerances, typically within ±0.2 mm, depending on part geometry and material,ideal for mission-critical components in high-performance applications.

Forging is used in industries like aerospace, automotive, defense, and heavy machinery for high-performance parts.

Manufyn forges a wide range of materials including carbon steel, alloy steel, stainless steel, aluminum, titanium, and brass, based on the application’s strength, temperature, and corrosion-resistance requirements.

Yes. We provide both closed-die (impression-die) and open-die forging depending on part complexity, size, and volume,offering flexibility for both custom forging and bulk production.

Absolutely. Our metal forging services include CNC machining, heat treatment, shot blasting, surface finishing, and quality inspection, delivering ready-to-use forged components.

Yes, forging is an ideal process for mass production, especially when parts require exceptional strength and durability.