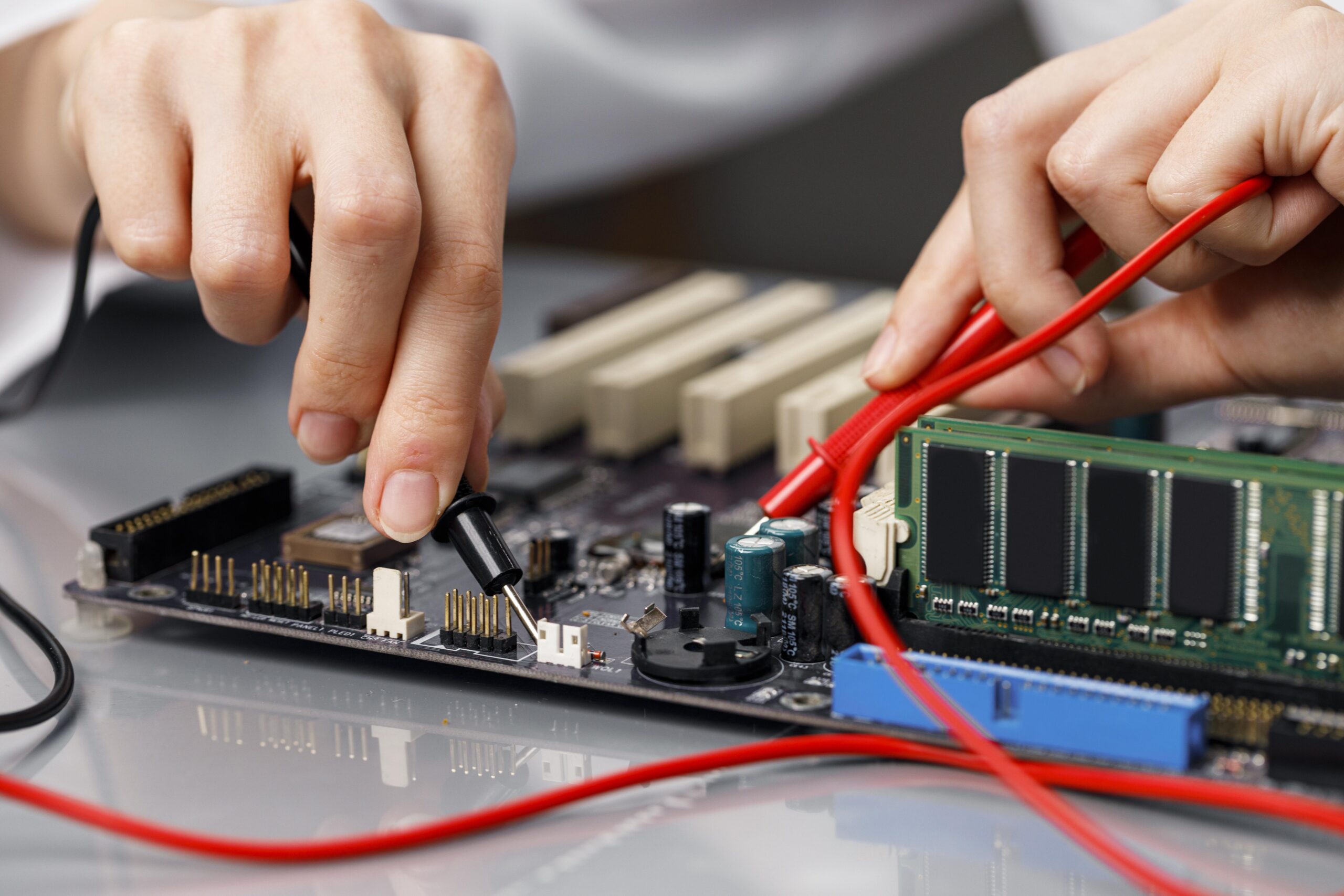

Wire Bonding Services for Reliable Microelectronic Connections

Precision Wire Bonding for Microelectronics & Semiconductor Packaging

Manufyn offers high-precision wire bonding services for semiconductor devices, integrated circuits (ICs), sensors, and microelectronic assemblies. Using state-of-the-art wire bonding machines, we ensure reliable electrical connections with controlled loop profiles, minimal stress, and superior bond strength.