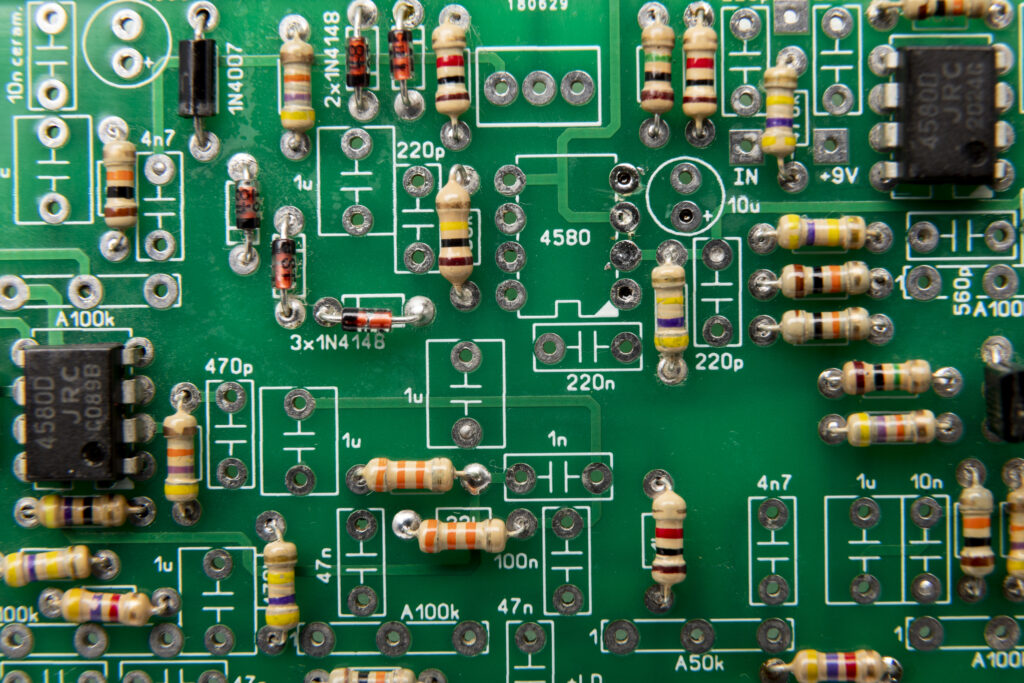

BGA Assembly Services for High-Density Electronic Boards

High-Precision BGA Soldering for Complex PCB Designs

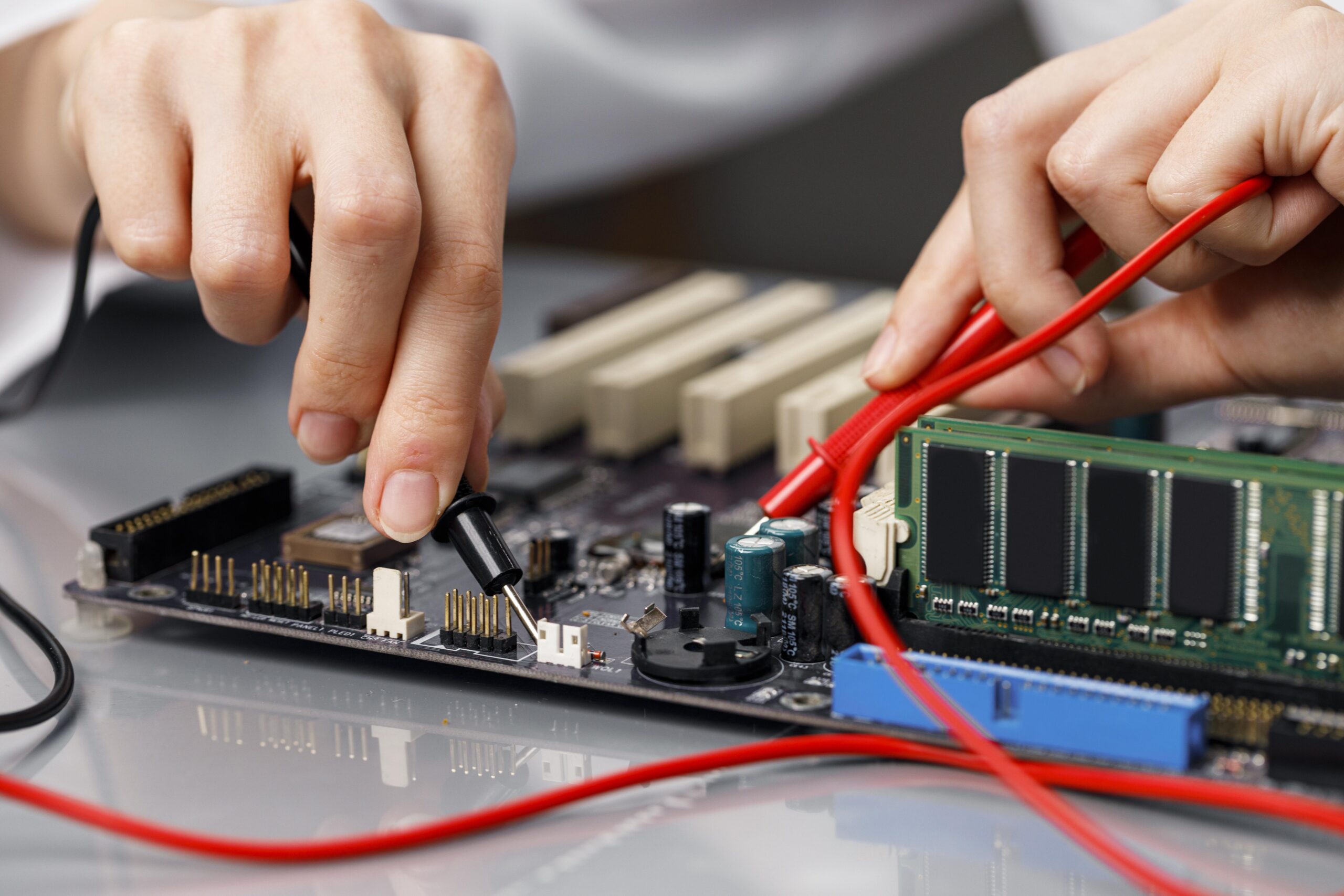

Manufyn offers advanced BGA assembly services for high-density, performance-critical electronic products. Using reflow profiling, X-ray inspection, and precision placement tools, we ensure every ball grid array (BGA) is correctly soldered with strong electrical and mechanical connections.