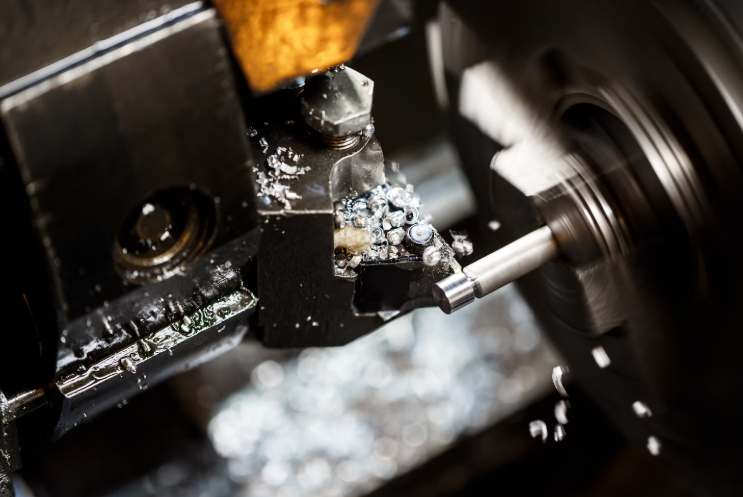

CNC Machining Services for Precision Metal Components

This advanced method is vital for prototype manufacturing, enabling industries to create intricate, custom-designed parts quickly and consistently. Whether for CNC machined rapid prototyping or full-scale production, CNC machining offers the precision, scalability, and versatility modern manufacturing demands.