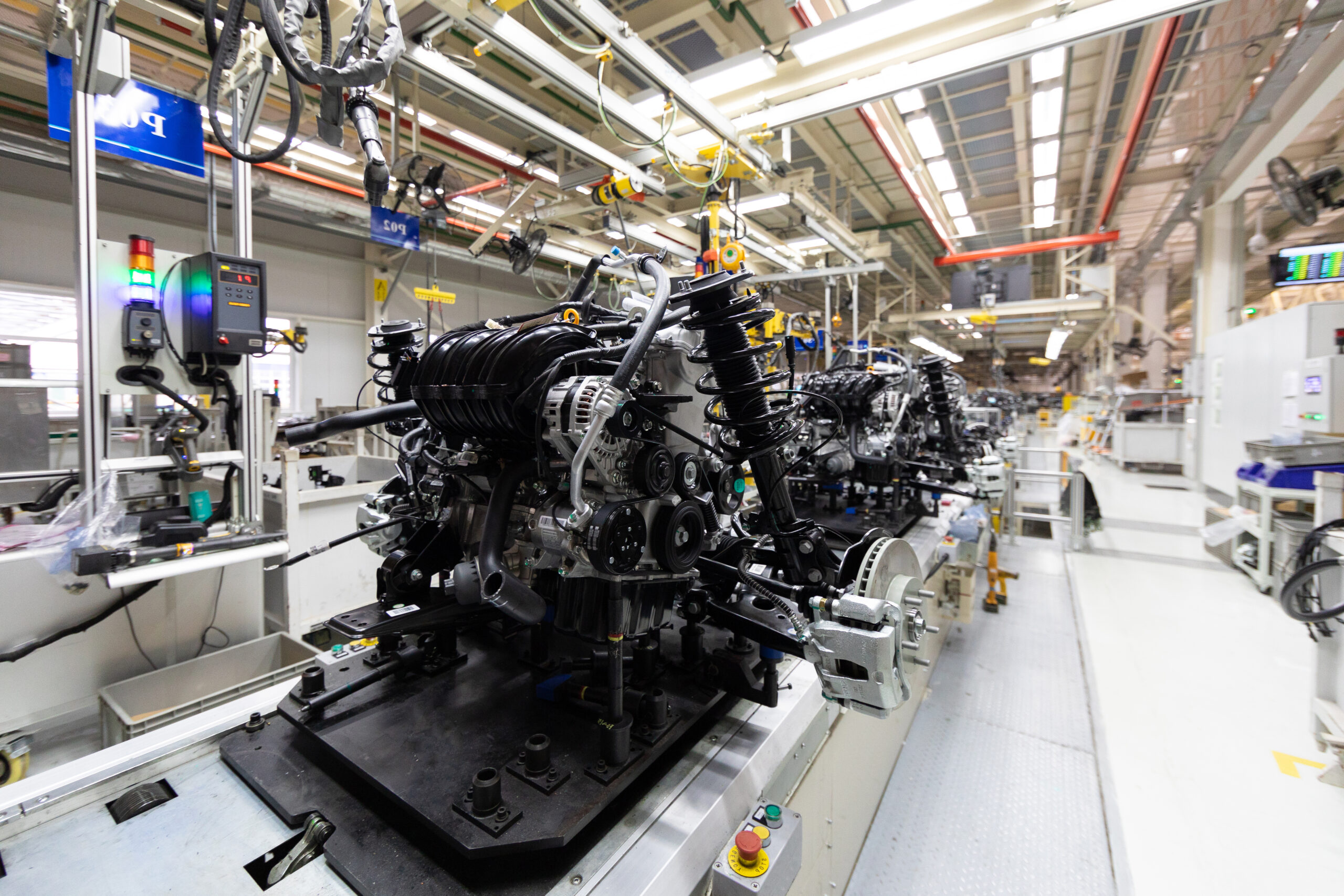

Investment Casting Services

for Complex, Detailed Metal Parts

Manufyn delivers world-class investment casting services for clients that demand intricate designs, dimensional accuracy, and excellent surface finish. Known for its versatility and repeatability, the investment casting process is ideal for producing small to medium-sized metal investment casting parts used across industries like aerospace, automotive, and industrial machinery..