Die Casting Services for Lightweight, High-Precision Metal Parts

High-Precision Metal Casting for Mass Production

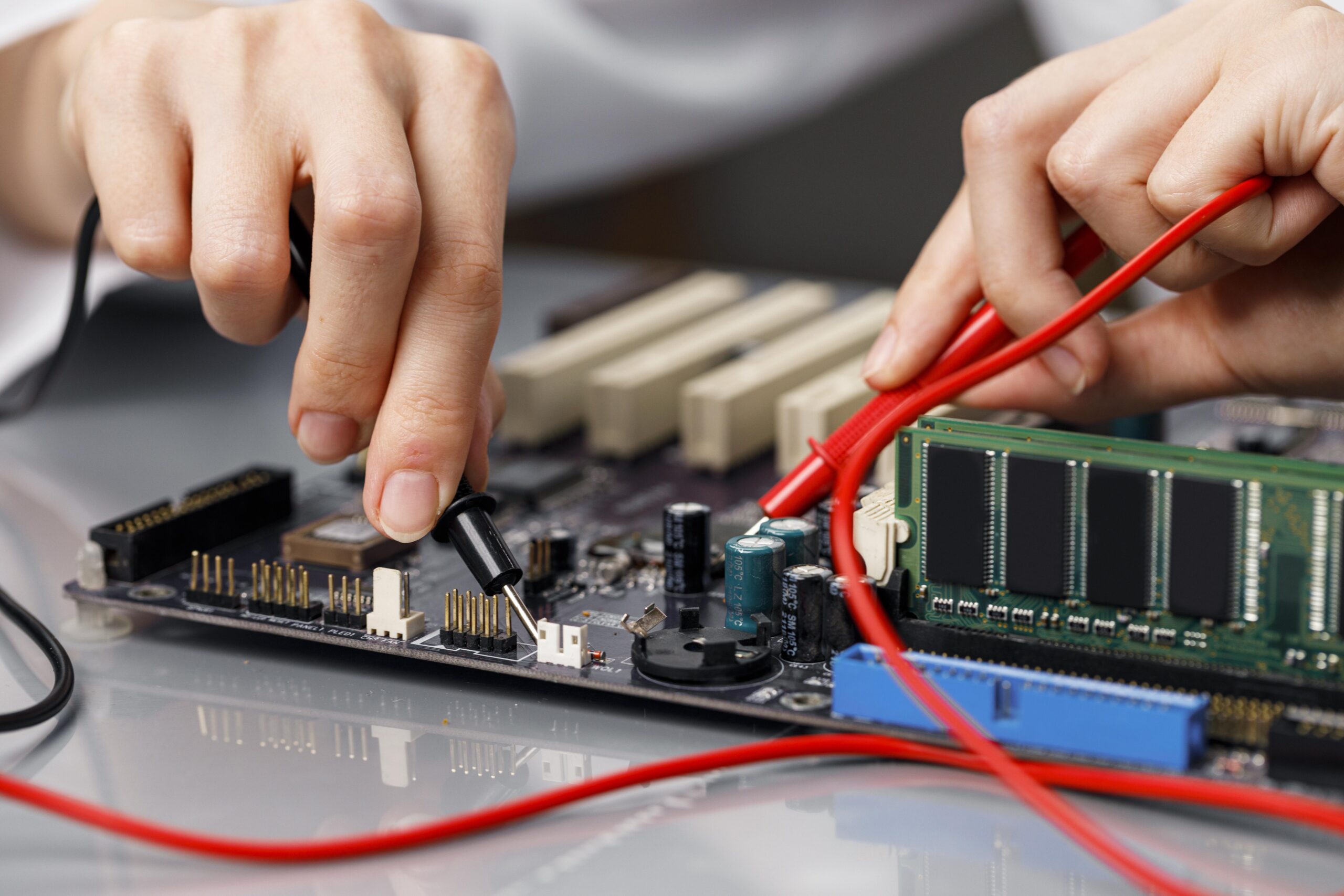

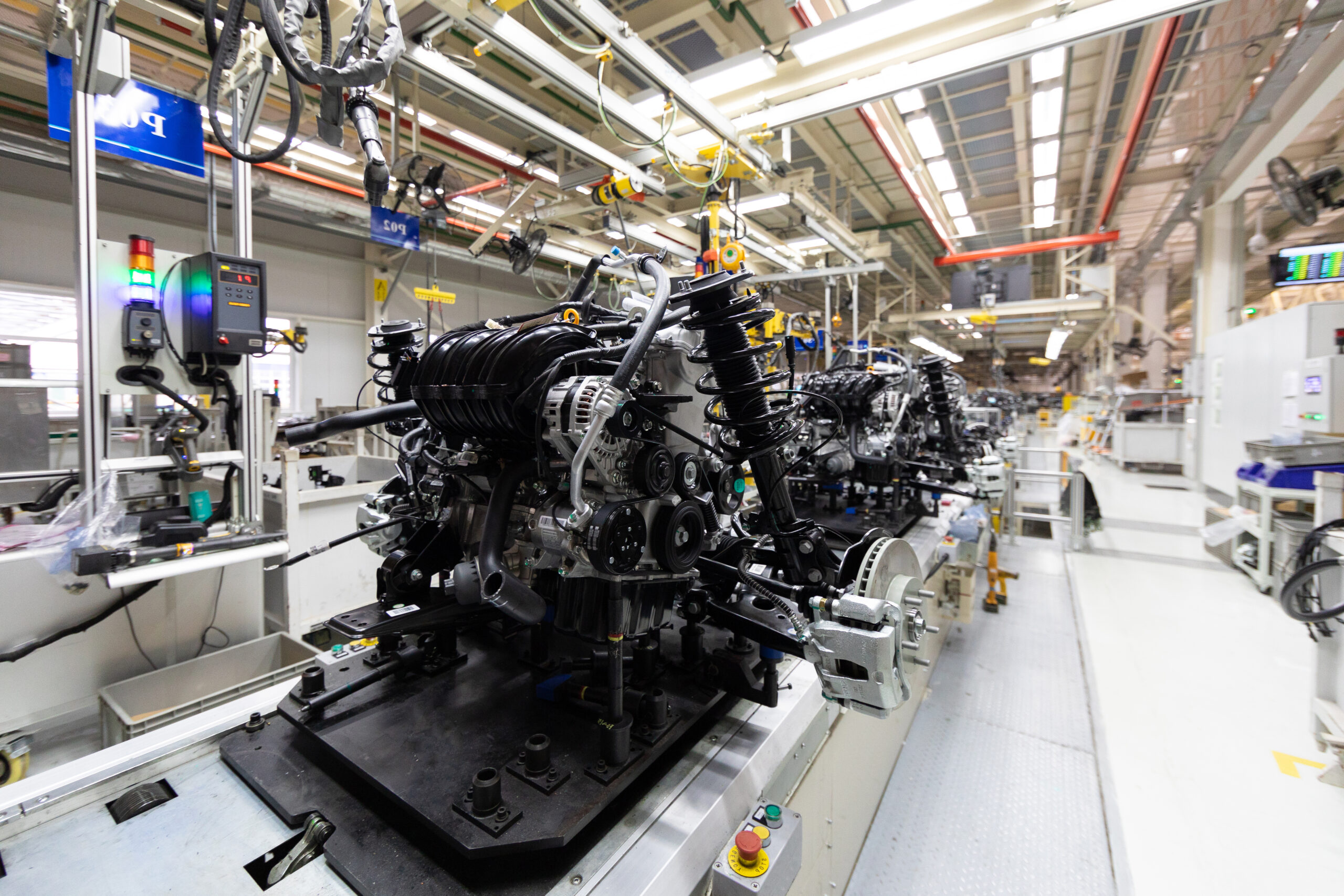

Manufyn delivers advanced die casting services for businesses seeking high-volume, dimensionally accurate, and durable metal components. From lightweight aluminium die casting components to structural parts made with precision, we support industries like automotive, electronics, and machinery with fast, repeatable production cycles using state-of-the-art die casting machines.