1M+

Parts

Delivered

100+

Global

Clients

500+

Vendors

Onboard

25+

Industries

Served

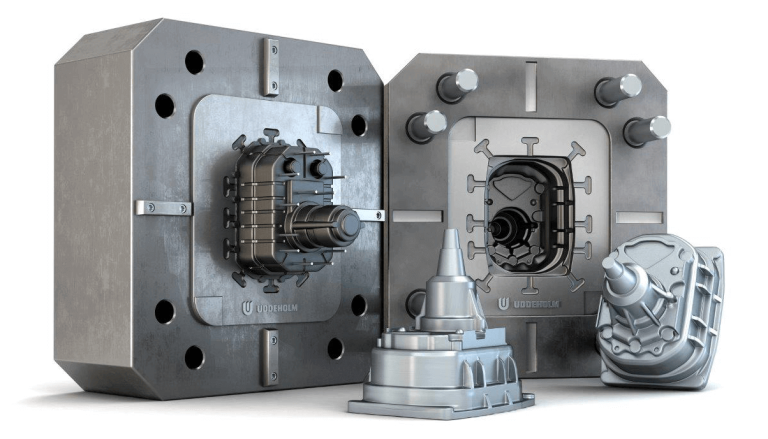

What is Metal Casting?

Metal casting is a foundational casting manufacturing process in which molten metal is poured into a mold to form complex parts. This technique is widely used across industries like automotive, aerospace, heavy machinery, and industrial equipment due to its ability to deliver high-strength, intricate components.

Why Choose Custom Metal Casting for Your Projects?

Custom metal casting is the preferred choice when you need high-quality, custom-designed metal parts. Unlike traditional machining, casting can handle complex shapes and designs that may be impossible to create with other manufacturing processes. Manufyn’s expertise in metal casting services ensures that your parts meet stringent industry standards, offering excellent strength, consistency, and performance.

Benefits of Custom Metal Casting

With Manufyn’s metal casting services, you get components that balance performance, precision, and affordability.

Complex Designs

Ideal for intricate components and fine detail.

High Strength & Durability

Ensures parts meet demanding application requirements.

Material Versatility

Compatible with aluminum, steel, iron, and other alloys.

Cost-Effective at Scale

Especially effective in mass production with minimal material waste.

Custom Mold Solutions

We design and fabricate custom metal casting mold solutions tailored to your product.

Types of Metal Casting Services We Offer

We provide comprehensive casting solutions to meet diverse production requirements:

The Casting Manufacturing Process: Step-by-Step

Understanding the casting manufacturing process helps in making better production decisions:

Pattern Design

A pattern is created using wax, plastic, or metal. This serves as the blueprint for the mold cavity.

Mold Creation

Molds are formed around the pattern using sand or permanent molds depending on the process.

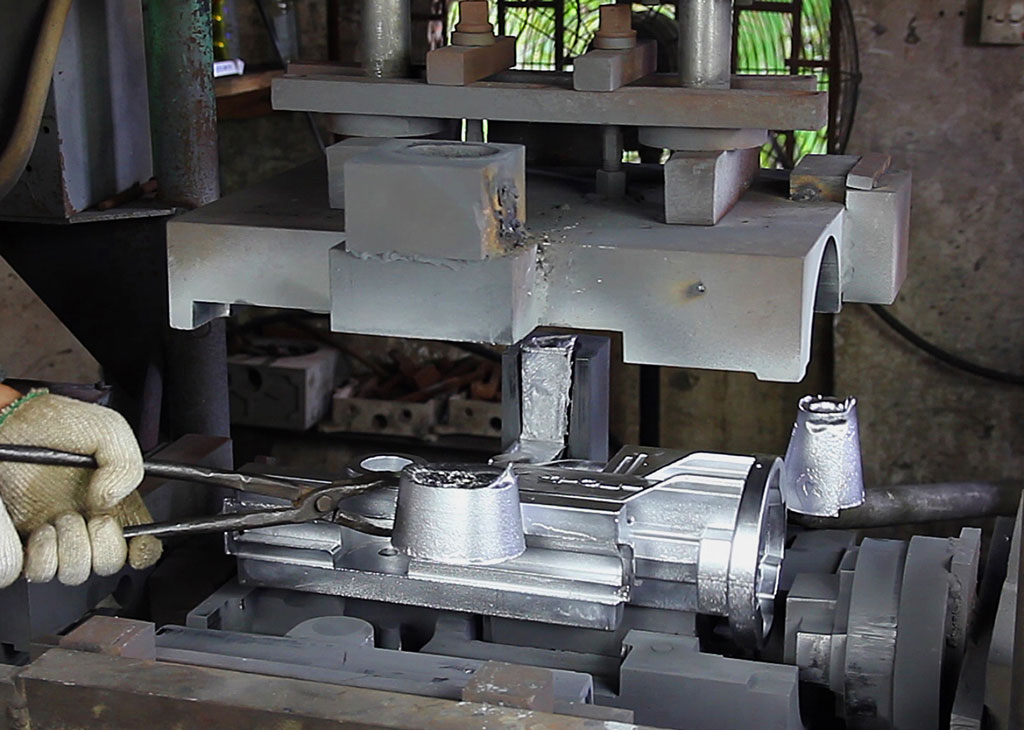

Molten Metal Pouring

Metal is melted and poured into the mold cavity under controlled conditions to minimize defects.

Cooling, Removal & Finishing

After solidification, the mold is removed, and the part is cleaned, machined, or polished as required.

Why Manufyn is Your Ideal Partner for Custom Metal Casting

Manufyn is known for delivering high-quality custom metal casting services, specializing in both aluminum die casting and other precision casting methods. Whether you need complex, custom components or mass-produced parts, we ensure that each piece meets your exact specifications with superior quality and durability.

Experienced Metal Fabricators

We have a team of experts who understand the intricacies of metal casting processes.

Advanced Technology

We utilize modern casting technologies and tools to deliver optimal results with precision.

Flexible Production

From small runs to large-scale manufacturing, our casting services are adaptable to various production needs.

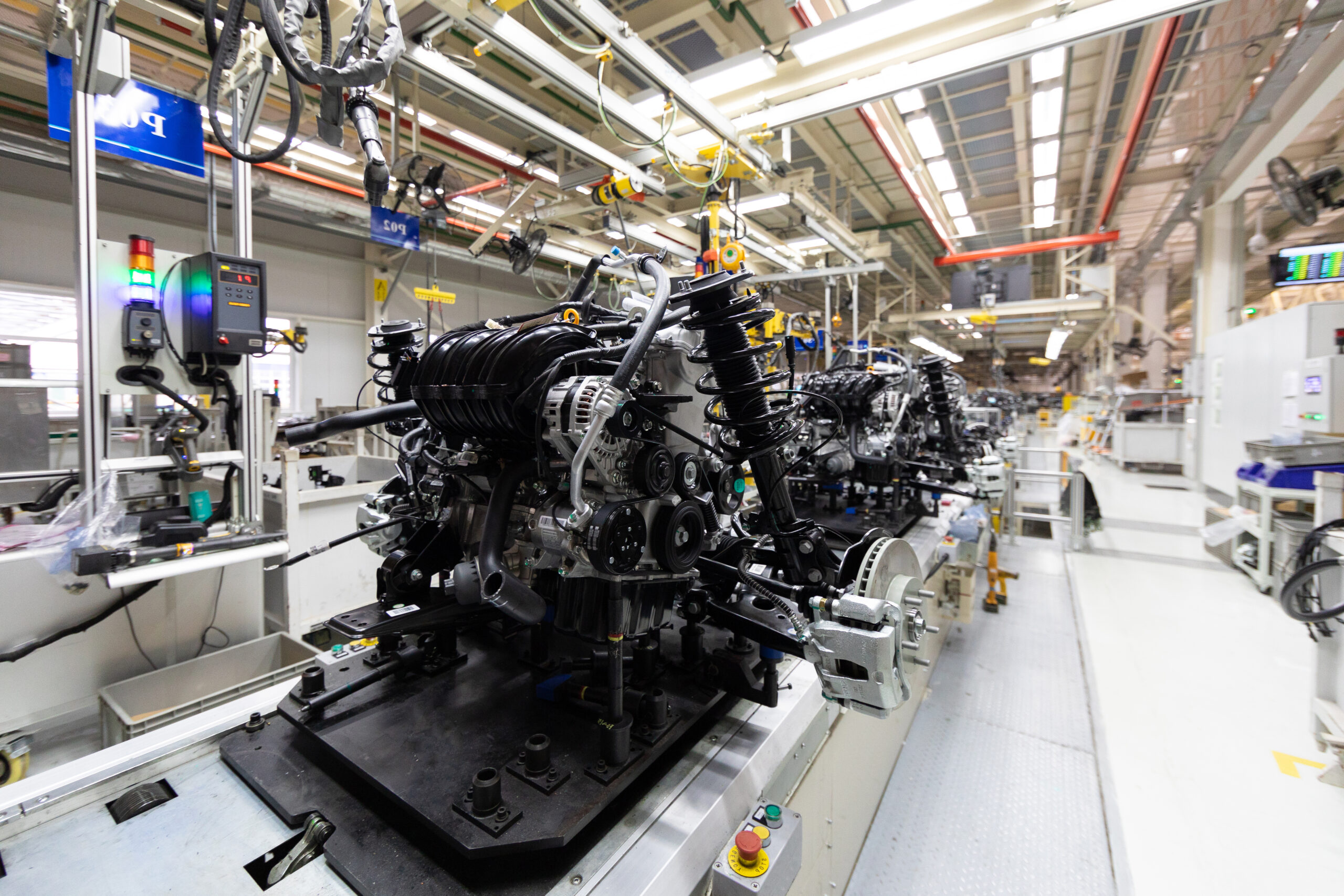

Applications of Metal Casting

Partner with Manufyn for Precision Metal Casting

Whether you need precision aluminum die-casting services or custom metal fabrication, Manufyn provides top-quality metal casting solutions that cater to all your needs. Our team is ready to take your projects from design to delivery with unmatched expertise.

Get Instant Quote

Frequently Asked Questions

Custom metal casting is the process of creating metal parts by pouring molten metal into custom-designed molds, allowing for intricate and complex shapes.

Aluminum die casting is highly efficient for mass production, offering excellent precision, strength, and surface finish for aluminum parts.

Metal casting involves pouring molten metal into molds, while forging involves shaping solid metal under high pressure to create the desired part.

Custom metal fabricators design and produce the molds required for casting, ensuring the final parts meet the necessary specifications and tolerances.

Yes, metal casting, especially methods like die casting, is ideal for mass production due to its ability to produce high-volume, consistent parts.

Manufyn offers expert knowledge in custom metal casting, ensuring high-quality, cost-effective solutions for a wide range of industries.

Manufyn offers metal casting services using a wide range of materials including aluminum, brass, bronze, steel, cast iron, and zinc alloys, depending on your performance, strength, and corrosion-resistance needs.

We provide multiple casting methods such as sand casting, investment casting, gravity die casting, and pressure die casting—each selected based on your product’s complexity, volume, and cost targets.

Yes. In addition to custom metal casting, we offer CNC machining, deburring, shot blasting, powder coating, and anodizing to deliver ready-to-assemble components.

Our metal casting services serve a wide range of sectors including automotive, aerospace, energy, agriculture, construction, and industrial equipment, delivering parts like housings, brackets, engine components, and structural frames.