The manufacturing world is moving faster than ever. From smart machines that learn on their own to digital platforms that connect entire production lines, technology is transforming how factories operate.

As we enter 2026, manufacturers across the globe are rethinking their strategies — focusing not only on production efficiency but also on data-driven decision-making, sustainability, and flexibility. New tools and technologies are redefining what’s possible, making factories more intelligent, responsive, and profitable.

For modern manufacturers, keeping up with these changes is no longer optional. Those who adapt quickly will see gains in productivity, cost savings, and market reach — while those who resist innovation risk being left behind.

Manufyn is at the forefront of this shift, helping manufacturers leverage emerging technologies to streamline processes, improve product quality, and future-proof operations. Whether it’s automation, AI, or digital manufacturing, Manufyn’s expertise bridges the gap between technology and tangible business outcomes.

Why Keeping Up With Manufacturing Tech Trends Matters

Technology is the foundation of modern manufacturing. Each innovation — from robotics to real-time data — offers an opportunity to work smarter, reduce waste, and enhance product value. However, staying updated isn’t just about installing the latest software or machinery; it’s about building adaptability into your organization’s DNA.

Here’s why keeping up with manufacturing technology trends matters in 2026:

- Competitive Advantage: Companies that adopt emerging technologies earlier often gain a strong lead through improved efficiency and faster product delivery.

2. Cost Optimization: Digital tools help manufacturers reduce material wastage, energy use, and downtime — directly boosting profitability. - Enhanced Quality Control: Automation and real-time monitoring ensure consistent product quality and faster issue resolution.

- Sustainability and Compliance: Eco-friendly technologies help manufacturers meet sustainability goals while adhering to evolving global standards.

- Workforce Empowerment: Advanced tools such as AI-driven analytics and augmented reality make work easier and safer for operators.

In short, keeping pace with technology isn’t just about staying current — it’s about staying relevant. The factories of the future will be data-centric, automated, and agile, and the time to adapt is now.

15 Manufacturing Technology Trends to Watch in 2026

Manufacturing in 2026 is about more than production lines, it’s about intelligence, integration, and innovation. Here are the top 15 technology trends shaping the future of the industry and what they mean for manufacturers.

1. Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are revolutionizing decision-making, predictive maintenance, and quality control in manufacturing. By analyzing real-time data, AI helps manufacturers anticipate machine failures and optimize production.

The global AI in manufacturing market is projected to grow from USD 34.18 billion in 2025 to USD 155.04 billion by 2030 (CAGR 35.3%).

2. Industrial Internet of Things (IIoT)

IIoT connects machines and sensors to share data in real time, enabling predictive analytics and smart decision-making. Manufacturers can track performance, energy use, and maintenance needs seamlessly.

The U.S. Industrial IoT market is expected to grow at a CAGR of 18% from 2025 to 2030, driven by connected production ecosystems.

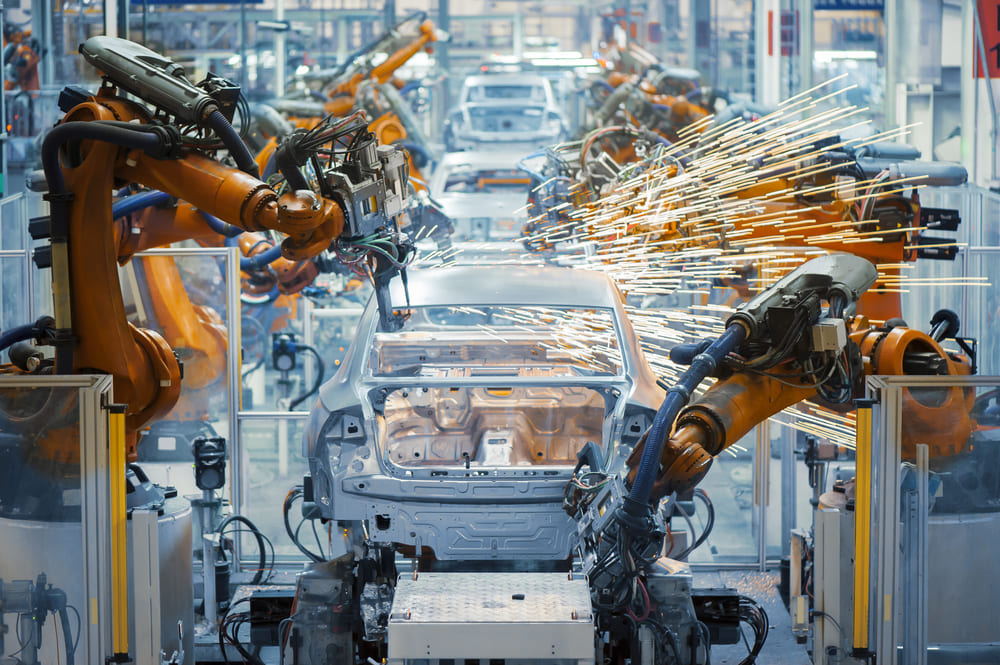

3. Advanced Automation and Robotics

Automation now goes beyond repetitive work — smart robots handle complex assembly and inspection tasks. Collaborative robots (cobots) can work safely with humans, improving output and flexibility.

By 2030, robotics adoption is expected to grow at a compound annual rate exceeding 20%, led by small and mid-scale manufacturers adopting cobots.

(Source: IFR)

4. Additive Manufacturing (3D Printing)

3D printing allows on-demand production with reduced waste. In 2026, it’s expected to become mainstream for low-volume production and custom part fabrication.

The global 3D printing market is forecasted to reach USD 98 billion by 2032, growing at a CAGR of 18.9%.

5. Digital Twins and Virtual Simulation

Digital twins let manufacturers create virtual replicas of machines, systems, or processes — optimizing performance before production begins.

Companies using digital twins report up to 30% faster product development cycles and 20% lower maintenance costs.

6. Smart Factories and Industry 4.0 Integration

Smart factories use connected systems and data analytics to automate and monitor operations end-to-end.

The global smart manufacturing market was valued at USD 349.81 billion in 2024 and is projected to reach USD 790.91 billion by 2030 (CAGR ~14%).

(Source: Grand View Research)

7. Cloud Manufacturing and Edge Computing

Cloud platforms streamline collaboration across supply chains, while edge computing processes data locally for real-time responsiveness. Together, they reduce latency and boost scalability.

Edge computing adoption in manufacturing is expected to increase by 45% by 2026, as industries pursue faster data processing.

(Source: Gartner)

8. Big Data Analytics in Production

Manufacturers rely on data analytics to optimize processes, detect inefficiencies, and improve resource planning.

Data-driven manufacturing has been shown to improve overall equipment effectiveness (OEE) by 15–25%.

9. Augmented Reality (AR) and Virtual Reality (VR)

AR/VR tools are improving worker training, equipment maintenance, and design visualization. Operators can view step-by-step instructions in real time, reducing errors and training costs.

AR in industrial applications is expected to grow at a CAGR of 31.6% from 2025 to 2030.

(Source: Markets and Markets)

10. Sustainable and Green Manufacturing Technologies

Sustainability is a business imperative. Green manufacturing emphasizes renewable energy, circular production, and waste reduction.

Global investment in green manufacturing technology is projected to grow at over 20% annually through 2030.

11. Cybersecurity in Smart Manufacturing

With more connected systems, cybersecurity is vital for protecting industrial data and production systems.

Manufacturing was the most targeted industry for cyberattacks in 2024, accounting for 25% of global ransomware incidents.

(Source: IBM X-Force Threat Intelligence Index)

12. Blockchain for Supply Chain Transparency

Blockchain builds trust by creating tamper-proof supply chain records. It helps ensure authenticity, traceability, and compliance across vendors.

Over 40% of global manufacturers are piloting or adopting blockchain-based supply chain systems.

(Source: PwC)

13. Collaborative Robots (Cobots)

Cobots make automation accessible to small and mid-sized manufacturers, easily handling tasks like packaging, assembly, and inspection.

The global cobot market is projected to grow from USD 1.9 billion in 2023 to USD 11.8 billion by 2030, at a CAGR of 36.3%.

(Source: Markets and Markets)

14. Predictive Maintenance and Smart Monitoring

Using AI and IoT, predictive maintenance helps anticipate issues before breakdowns occur, reducing downtime.

Predictive maintenance can reduce unplanned downtime by 30–50% and increase machine life by 20–40%.

(Source: AtheerAir)

15. Advanced Materials and Nanotechnology

The development of stronger, lighter, and more sustainable materials is reshaping design and manufacturing performance.

The global nanotechnology market is projected to reach USD 250 billion by 2030, driven by applications in manufacturing and energy.

(Source: Precedence Research)

How These Technologies Are Changing the Manufacturing Landscape

The convergence of advanced technologies is not just modernizing manufacturing — it’s completely redefining how factories operate, innovate, and compete. Here’s how these trends are reshaping the manufacturing ecosystem in 2026 and beyond.

1. Data-Driven Decision-Making

From predictive analytics to AI-powered dashboards, manufacturers are moving away from intuition-based management toward data-backed operations.

Real-time insights help leaders make faster, smarter, and more profitable decisions — whether it’s adjusting production schedules or forecasting demand.

2. Personalized and Agile Production

Technologies like 3D printing, robotics, and digital twins make it possible to produce customized products at scale.

This shift toward mass personalization allows manufacturers to serve niche markets and respond to changing consumer preferences without increasing costs.

3. Connected Ecosystems and Smart Supply Chains

IIoT and blockchain have made it possible to track every component across the supply chain.

With connected logistics, manufacturers gain better visibility into sourcing, production, and delivery — ensuring efficiency, compliance, and transparency.

4. Reduced Downtime and Improved Equipment Lifespan

Predictive maintenance powered by AI and sensors ensures that machines are serviced before failures occur.

This leads to 30–50% fewer breakdowns, better asset utilization, and longer equipment life — directly boosting profitability and productivity.

5. Enhanced Worker Safety and Training

AR and VR tools are transforming how workers learn and operate machinery.

Technicians can follow real-time 3D guides, reducing errors and improving safety in complex production environments.

This results in a workforce that’s skilled, confident, and tech-empowered.

6. Sustainable Manufacturing Becomes Mainstream

Green manufacturing is no longer a choice — it’s a competitive necessity.

Factories that adopt renewable energy, waste recycling, and energy-efficient systems are not only reducing their carbon footprint but also cutting operational costs.

Consumers and investors alike now prefer brands that align with sustainability goals.

7. Greater Collaboration Across the Value Chain

Cloud-based manufacturing and digital platforms allow teams to collaborate from design to delivery in real time.

This integrated workflow improves project speed, design accuracy, and client satisfaction — especially in global operations.

8. Democratization of Technology

Previously, innovations like robotics and AI were accessible only to large enterprises.

Today, SMEs are equally empowered — thanks to affordable cobots, SaaS-based digital tools, and modular manufacturing setups.

This has created a level playing field where agility often beats scale.

9. Accelerated Time-to-Market

With digital simulations, 3D modeling, and automated testing, manufacturers can validate designs faster and move products from concept to customer in record time.

This time-to-market reduction gives businesses a strategic edge in fast-evolving industries.

10. Building Resilience for the Future

Perhaps the most important shift is resilience.

Manufacturers embracing technology are better equipped to handle supply chain disruptions, resource shortages, and shifting market demands — ensuring long-term stability and growth.

Where Manufyn Fits In

As manufacturing evolves into a smarter, greener, and more connected ecosystem, businesses need a trusted partner who understands both technology and execution. That’s where Manufyn steps in.

Manufyn bridges the gap between innovation and implementation, helping manufacturers adopt new technologies without disrupting ongoing operations.

From digital product design and prototyping to smart manufacturing integration and supply chain optimization, we deliver solutions that make factories more intelligent, efficient, and sustainable.

Here’s how Manufyn helps manufacturers stay ahead:

1. Digital Product Design & Development

We transform ideas into market-ready products through end-to-end design, prototyping, and validation.

Our digital-first approach minimizes errors, reduces costs, and accelerates product launches.

2. Smart Factory Enablement

Manufyn enables industries to modernize production lines with automation, IoT integration, and real-time analytics — ensuring efficiency, consistency, and scalability.

We help clients move toward data-driven manufacturing ecosystems where every process is optimized for performance.

3. Sustainable Manufacturing Solutions

Sustainability isn’t just an initiative — it’s part of our design thinking.

We help businesses adopt energy-efficient systems, reduce waste, and improve material utilization, ensuring eco-friendly production without compromising profitability.

4. Process Optimization and Cost Reduction

Through predictive maintenance, workflow automation, and lean process design, we help manufacturers achieve significant cost savings and performance improvements across operations.

5. Collaborative and Scalable Models

Every manufacturer is different — that’s why Manufyn offers customized engagement models.

Whether you’re a startup scaling production or an enterprise optimizing existing systems, we tailor our approach to your specific goals and growth stage.

Why Manufacturers Trust Manufyn

- Proven expertise in product design, development, and manufacturing optimization

- Commitment to innovation, quality, and sustainability

- Hands-on collaboration and transparent communication at every stage

A team that understands both technology trends and ground-level challenges

Conclusion: The Future Belongs to the Tech-Ready Manufacturer

The manufacturing industry in 2026 is not just about automation — it’s about intelligence, adaptability, and sustainability.

From AI-driven insights to smart factories and green technologies, the pace of innovation is reshaping how products are designed, built, and delivered.

Manufacturers that stay ahead of these trends will not only improve efficiency but also gain a competitive edge in cost, quality, and agility.

Whether it’s embracing predictive maintenance, digital twins, or sustainable production models — the future favors those who act early.

Frequently Asked Questions FAQs

The top manufacturing technology trends in 2026 include AI and machine learning, industrial IoT, robotics, digital twins, sustainable manufacturing, and smart factories. These innovations are helping industries become more efficient, connected, and eco-friendly.

AI helps manufacturers predict equipment failures, optimize workflows, and improve quality control. It uses real-time data to make faster, data-driven decisions, reducing downtime and improving production efficiency.

A smart factory uses interconnected systems, automation, and data analytics to optimize production processes. It enables real-time monitoring, predictive maintenance, and efficient resource management — resulting in higher productivity and lower costs.

Sustainability reduces waste, energy use, and emissions while improving brand value and compliance. Green manufacturing also lowers operational costs by using renewable energy and circular production methods.

IIoT connects machines, sensors, and systems to collect and analyze data. It helps monitor equipment health, improve maintenance, and enhance operational visibility, making factories more responsive and intelligent.

Predictive maintenance uses AI and IoT to anticipate machine issues before they occur. This reduces unplanned downtime, extends equipment lifespan, and minimizes maintenance costs.

Automation focuses on performing repetitive tasks with minimal human input, while smart manufacturing combines automation with data analytics, IoT, and AI to enable adaptive, self-optimizing operations.

Digital twins create virtual models of physical systems to test performance, identify issues, and improve designs before production. This leads to faster product development and reduced production risks.

Small manufacturers can adopt modular automation, cloud-based tools, and collaborative robots (cobots). Partnering with experts like Manufyn helps them scale efficiently without heavy upfront investments.

Manufyn provides end-to-end support for modernizing manufacturing — from digital product design to smart factory implementation. With expertise in technology integration, sustainability, and cost optimization, Manufyn helps businesses stay ahead of industry trends.

Ready to Make Your Manufacturing Smarter with Manufyn?

If you’re looking to adopt modern manufacturing technologies, streamline processes, or scale production efficiently — Manufyn can help you get there.

Our team specializes in transforming ideas into scalable, sustainable, and tech-powered solutions tailored to your business goals.

Let’s build the factory of the future — together.

Get in touch with Manufyn today to start your transformation journey.