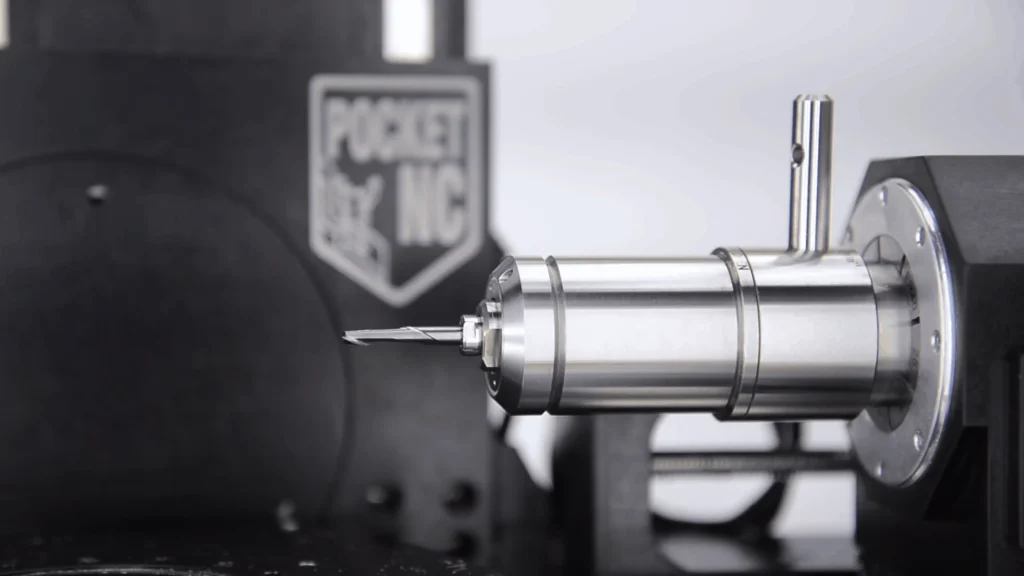

Prevent tool breakage with Manufyn’s design checks.

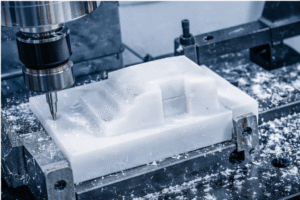

Pockets and slots are among the most time-intensive features in CNC machining. While they may appear simple in CAD, these features require significant material removal and continuous tool engagement. As a result, poor pocket or slot design directly increases machining time, tool wear, and overall part cost.

Unlike external profiles, pockets and slots restrict chip evacuation and limit tool rigidity. Deep or narrow features amplify cutting forces, which can lead to chatter, tapered walls, and inconsistent surface finish. Therefore, pocket and slot geometry plays a critical role in determining whether a part machines efficiently or requires conservative parameters that increase cycle time.

From a manufacturability perspective, pockets and slots often drive tool selection, step-down strategy, and the number of machining passes required. Even small design changes—such as increasing internal radii or adjusting depth-to-width ratios—can significantly improve machining stability. Designing these features with CNC constraints in mind reduces DFM iterations and improves first-pass success.

Pockets vs Slots — Understanding the Difference in CNC

Although pockets and slots are both recessed features, CNC machining treats them very differently. Understanding this distinction helps designers predict cost, machining risk, and feasibility early in the design process.

What Qualifies as a Pocket in CNC Machining

A pocket is typically a closed or semi-closed recessed area where the cutting tool has room to move laterally. Because the cutter can enter, ramp, and clear material gradually, pockets allow more flexible toolpaths and better control over cutting forces. As a result, pockets are generally more stable to machine than slots of similar depth.

Pockets also allow multiple tool diameters to be used during machining. Roughing tools can remove bulk material efficiently, while smaller finishing tools refine walls and floors. This flexibility often leads to better surface finish and dimensional consistency.

What Qualifies as a Slot in CNC Machining

A slot is a narrow channel where the tool is engaged on both sides simultaneously. This full-width engagement significantly increases cutting forces and heat. Consequently, slots are more prone to chatter, tool deflection, and premature wear, especially when depth increases.

Slots also limit tool choice. The cutter diameter must match the slot width, which restricts flexibility and often forces the use of long, slender tools. As a result, narrow or deep slots are among the highest-risk features in CNC machining.

Why Slots Are Harder to Machine Than Pockets

The key difference lies in tool engagement. In a pocket, the cutter engages partially and clears chips more effectively. In a slot, the cutter is fully engaged, leaving little room for chips to escape. Therefore, slots require slower feeds, multiple passes, or specialized strategies to maintain stability.

From a cost standpoint, slots typically take longer to machine than pockets of comparable size. Recognizing this difference early allows designers to adjust geometry—such as widening slots or converting them into open pockets—when function permits.

Not sure whether a pocket or slot is the right choice for your design?

Pocket Depth, Width & Aspect Ratio

Pocket geometry has a direct impact on machining stability and cycle time. As pocket depth increases, the effective length of the cutting tool must also increase. This reduces tool rigidity and raises the risk of deflection, chatter, and tapered walls. Therefore, pocket depth should always be evaluated relative to tool diameter and material choice.

Depth-to-Tool-Diameter Relationship

In CNC machining, pocket depth is closely tied to the diameter of the cutting tool used. Deeper pockets require longer tools, which flex more under cutting forces. As a result, excessive depth often forces slower feeds, additional finishing passes, or multiple step-downs to maintain accuracy.

Designers should avoid deep pockets with small widths whenever possible. Wider pockets allow the use of larger diameter tools, which improves rigidity and shortens machining time. Consequently, increasing pocket width can often reduce cost more effectively than reducing depth alone.

Aspect Ratio and Machining Stability

The aspect ratio of a pocket—defined as depth relative to width—plays a critical role in machining performance. High aspect ratio pockets concentrate cutting forces along long tool lengths, which increases vibration and surface finish variation. Over time, this also accelerates tool wear.

From a design perspective, lowering the aspect ratio improves stability and consistency. If functional requirements demand a deep pocket, adding internal steps or splitting the pocket into multiple levels can help maintain tool rigidity and reduce machining risk.

Multiple Step-Down Strategies

Deep pockets typically require multiple step-down passes rather than a single deep cut. While this approach improves control, it increases cycle time. Therefore, designers should be aware that deeper pockets not only add machining complexity but also compound time and cost through repeated tool engagement.

Slot Width & Depth Design Constraints

Slots introduce a different set of machining challenges due to full-width tool engagement. Unlike pockets, slots restrict lateral tool movement and limit chip evacuation. As a result, slot geometry must be designed with greater care to avoid excessive cutting forces and instability.

Minimum Slot Width Considerations

Slot width determines the tool diameter that can be used. Narrow slots force the use of small-diameter cutters, which are inherently less rigid. This increases the likelihood of deflection and chatter, particularly as slot depth increases. Therefore, specifying the narrowest possible slot often leads to higher machining cost and reduced reliability.

When function allows, widening a slot even slightly can enable the use of a more robust tool. This simple change can significantly improve machining stability and reduce cycle time.

Slot Depth and Tool Engagement

Slot depth directly affects how much of the tool is engaged during cutting. Deeper slots increase contact length between the tool and material, which raises heat and cutting forces. Consequently, deep slots require slower feeds and multiple passes to maintain control.

Blind slots add further complexity because chips have limited escape paths. In such cases, machining strategies must be more conservative to prevent tool overload. Designers should consider through slots or open-ended geometries when possible to reduce risk.

Through Slots vs Blind Slots

Through slots allow chips to exit freely, making them easier to machine and more consistent in quality. Blind slots, however, trap chips and concentrate heat at the tool tip. As a result, blind slots are more prone to tool wear and dimensional variation. Selecting through slots when function permits improves both manufacturability and cost efficiency.

Validate slot dimensions and tooling feasibility before machining.

Internal Corners & Radii in Pockets and Slots

Internal corners are one of the most common design constraints in CNC machining. Because cutting tools are cylindrical, they cannot create perfectly sharp internal corners. As a result, all pockets and slots must include internal radii that match or exceed the tool radius.

Why Sharp Internal Corners Are Not Machinable

A sharp internal corner forces the cutting tool to stop or slow dramatically, which increases heat and tool wear. In many cases, sharp corners are simply impossible to machine without specialized tooling or secondary processes. Therefore, designing pockets and slots with zero-radius corners leads to increased cost or DFM revisions.

Tool Radius vs Internal Corner Radius

The internal corner radius must be at least equal to the radius of the cutting tool used. When the corner radius is too small, machinists are forced to use smaller tools, which are less rigid and slower to operate. Consequently, overly tight corner radii increase machining time and reduce surface quality.

Providing larger radii allows the use of standard tooling, improves chip evacuation, and enables smoother toolpaths. Even modest increases in internal radius can significantly reduce machining complexity.

Design Strategies for Corner Relief

When sharp internal corners are functionally required, designers can introduce relief features such as dog-bone or T-bone cutouts. These allow mating parts to fit while maintaining tool access. However, relief features add complexity and should be used only when necessary. Whenever possible, functional requirements should be reviewed to allow for generous internal radii.

Tool Access & Machining Strategy for Pockets and Slots

Tool access determines whether pockets and slots can be machined efficiently or require additional setups and complex strategies. Poor access increases machining time, reduces accuracy, and raises the risk of tool collision.

Vertical Access and Tool Approach

Most CNC machining assumes vertical tool access. Features that block vertical entry force the use of angled approaches or multi-axis machining. As a result, pockets with overhangs or enclosed geometry often require 4-axis or 5-axis setups, which increase cost and programming time.

Designers should ensure that tools can reach pocket floors and slot walls directly whenever possible. Clear access simplifies toolpaths and improves dimensional consistency.

Single-Setup vs Multi-Setup Machining

Pockets and slots that can be machined in a single setup are generally more accurate and cost-effective. Each additional setup introduces re-clamping, re-zeroing, and potential alignment error. Therefore, designing features that align with a single machining orientation improves repeatability.

When features exist on multiple faces, designers should evaluate whether they are functionally necessary or can be consolidated to reduce setup count.

When Multi-Axis Machining Is Required

Some pocket and slot geometries cannot be accessed with standard 3-axis machining. Angled pockets, deep side slots, or features under overhangs may require 5-axis machining. While this expands capability, it also increases cost. Consequently, designers should use multi-axis requirements only when geometry or function truly demands it.

Confirm tool access and setup strategy with manufacturing experts.

Material Impact on Pocket & Slot Design

Material selection significantly influences how pockets and slots behave during machining. Cutting forces, heat generation, and chip formation vary widely by material. Therefore, pocket and slot geometry that works well in one material may fail or become expensive in another.

Pockets and Slots in Aluminum

Aluminum machines easily and allows higher cutting speeds, however chip evacuation becomes critical in deep pockets. Chips can pack quickly if step-downs are too aggressive or internal radii are too tight. As a result, deeper pockets in aluminum often benefit from generous radii and open geometries that allow chips to clear efficiently.

Because aluminum supports larger tool diameters, designers can often increase pocket width slightly to improve rigidity and reduce cycle time without compromising function.

Pockets and Slots in Steel and Stainless Steel

Steel and stainless steel introduce higher cutting forces and heat. In deep pockets or narrow slots, this leads to chatter and accelerated tool wear. Consequently, depth limits become more restrictive, and conservative step-down strategies are required.

In stainless steel, work hardening further complicates machining. If tools dwell or feeds are too low, the material hardens locally, making subsequent passes more difficult. Therefore, pocket and slot designs in stainless steel should avoid excessive depth and narrow widths whenever possible.

Pockets and Slots in Plastics

Plastics behave differently under cutting forces. Heat buildup can cause melting, deformation, or poor surface finish inside pockets and slots. Thin walls surrounding deep pockets are especially prone to distortion.

To reduce these risks, designers should maintain consistent wall thickness and avoid deep, narrow features in plastic parts. Larger clearances and reduced depth help maintain dimensional stability.

Common Pocket & Slot Design Mistakes

Most pocket- and slot-related machining issues originate from design decisions made early in CAD. While these features may appear simple, small oversights can significantly increase machining time, tool wear, or part rejection. Recognizing these common mistakes helps prevent unnecessary DFM feedback and production delays.

Designing Excessively Deep Pockets

One of the most frequent issues is specifying pockets that are deeper than functionally required. As depth increases, tool rigidity decreases, which leads to chatter, tapered walls, and inconsistent surface finish. Consequently, deeper pockets often require multiple step-downs and finishing passes, increasing cycle time and cost without improving part performance.

Using Extremely Narrow Slots

Narrow slots force the use of small-diameter tools that are more prone to deflection and breakage. In addition, full-width tool engagement increases heat and cutting forces. As a result, narrow slots are among the slowest and riskiest features to machine. When possible, widening slots or converting them into open pockets improves stability and reduces machining time.

Specifying Sharp Internal Corners Everywhere

Sharp internal corners are a common CAD default but are not CNC-friendly. Tight corner radii force smaller tools, which increases machining time and reduces surface quality. Therefore, internal corners should be radiused generously unless sharp corners are functionally required.

Applying Tight Tolerances to Non-Functional Features

Designers often apply tight tolerances uniformly across all pockets and slots. However, most internal features do not require high precision. Over-tolerancing forces conservative machining strategies and additional inspection steps, which increases cost without adding value.

Ignoring Tool Access and Setup Constraints

Pockets and slots that cannot be accessed vertically often require multiple setups or multi-axis machining. These requirements increase programming complexity and reduce repeatability. Designers should evaluate tool access early to avoid unnecessary setup changes.

Design pockets and slots that machine efficiently the first time.

Best-Practice Checklist for Pocket & Slot Design

Well-designed pockets and slots balance functional requirements with machining practicality. Before releasing a design for CNC machining, engineers should confirm that internal features follow proven design principles.

Optimizing Pocket Geometry

Pocket depth should be minimized wherever possible, and width should be sufficient to allow the use of rigid tools. Lower aspect ratios improve stability and surface finish. If deep pockets are unavoidable, splitting them into multiple levels can reduce machining risk.

Designing Slots for Machining Stability

Slots should be as wide as function allows to enable stronger tools and better chip evacuation. Through slots are preferred over blind slots due to easier chip removal and lower heat buildup. When blind slots are necessary, conservative depth and generous radii improve reliability.

Specifying Internal Radii Thoughtfully

Internal corner radii should be sized to match standard tool diameters. Larger radii reduce tool wear, enable smoother toolpaths, and lower cycle time. Relief features should be used only when mating requirements demand sharp corners.

Applying Tolerances and Finishes Strategically

Tolerances and surface finish requirements should be applied only to functional pocket and slot surfaces. Standard machining tolerances are sufficient for non-critical internal features. This approach reduces machining time and simplifies inspection.

Reviewing Tool Access Before Release

Designers should verify that tools can access pocket floors and slot walls without obstruction. Features that require angled or side access should be reviewed carefully to confirm that added complexity is justified.

Frequently Asked Questions

How deep can a CNC pocket be machined reliably?

Pocket depth is limited by tool rigidity and material behavior. As depth increases, longer tools are required, which increases deflection and chatter. In general, pockets should be designed with a reasonable depth-to-width ratio to maintain machining stability and consistent surface finish.

Why are narrow slots expensive to machine?

Narrow slots force full-width tool engagement and require small-diameter cutters. This increases cutting forces, heat, and tool wear. As a result, narrow slots often need slower feeds and multiple passes, which increases cycle time and cost.

What is the minimum internal radius for pockets and slots?

The minimum internal radius must match or exceed the cutting tool radius. Tight internal radii force the use of smaller tools, which reduces rigidity and increases machining time. Providing larger radii allows faster, more stable machining with standard tooling.

Do pockets and slots need tight tolerances?

Only pockets and slots that serve a functional role—such as locating or guiding components—require tight tolerances. Non-functional internal features typically perform well with standard machining tolerances. Over-tolerancing increases machining and inspection cost without improving performance.

How does material choice affect pocket and slot design?

Different materials respond differently to cutting forces and heat. Aluminum allows faster machining but requires good chip evacuation, while steel and stainless steel demand more conservative depth and width limits. Plastics are sensitive to heat and may deform around deep pockets.

When should blind pockets or slots be avoided?

Blind pockets and slots trap chips and increase heat at the tool tip. They should be avoided when a through feature or open geometry can achieve the same function. When blind features are required, conservative depth and generous radii improve reliability.

Design pockets and slots that machine efficiently and stay within tolerance.

Upload your CAD file to Manufyn for a fast DFM review, machining feedback, and an accurate CNC manufacturing quote.