Manufyn aligns plastic selection with machining limits.

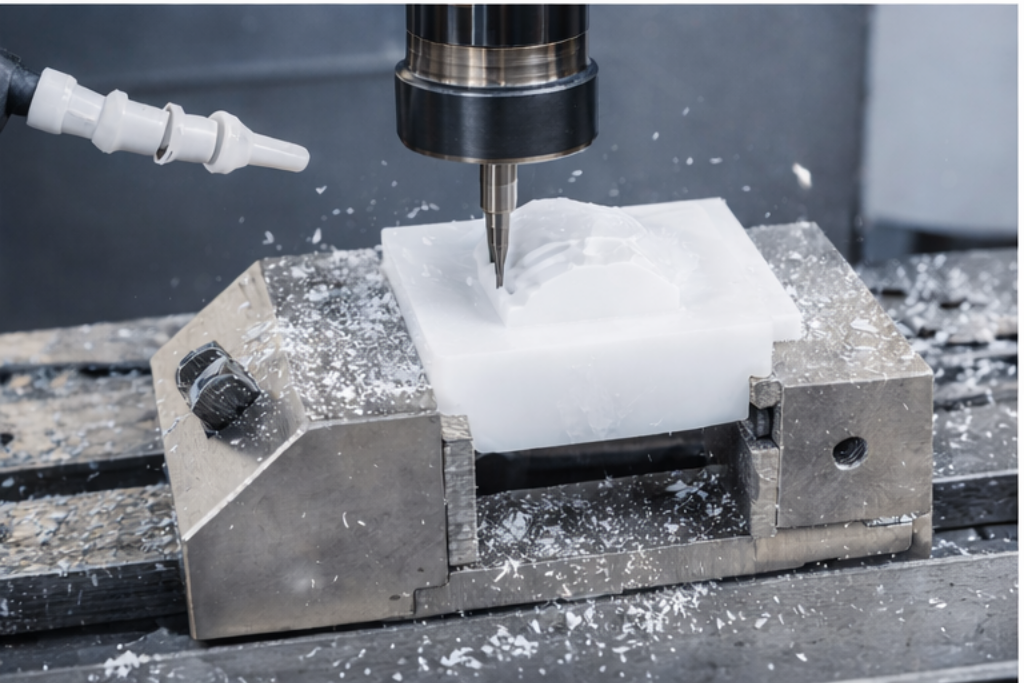

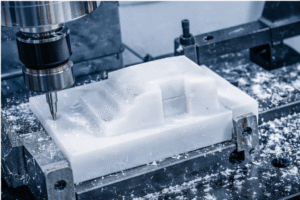

CNC machining for plastics is a subtractive manufacturing process used to create functional components from engineering polymers such as ABS, Nylon, Delrin (POM), Acrylic, and Polycarbonate. Unlike metal machining, a cnc machine for plastic is optimized for friction-sensitive polymers, controlled chip load, and heat-stable cutting conditions. This prevents warping, melting, and edge deterioration during production.

Teams choose plastic cnc machine workflows when they need:

- Tight tolerances before committing to tooling

- Functional prototypes that behave like production parts

- Small/medium batch runs without injection mold cost

- Stable parts for assemblies, fixtures, and fit-checks

- Faster manufacturing without reworking CAD files

At Manufyn, CNC machining is not a one-off service — it’s a scalable manufacturing path. We support EVT (engineering validation), DVT (design validation), PVT (production validation), and early mass production, making the process suitable for both prototyping and supply chain programs.

Before selecting a vendor or submitting an RFQ, it’s important to understand how CNC machines for plastic actually operate and where they differ from metal machining.

How CNC Machines for Plastic Actually Work

A plastic CNC machining setup uses programmed toolpaths (G-code) to remove material until the final dimension is achieved. The machine’s priority isn’t just cutting — it’s controlling thermal behavior, because plastics deform faster than metals when exposed to friction.

What Changes When Machining Plastics vs Metals

| Control Parameter | Metals (General) | Plastics (Adjustment) |

|---|---|---|

| Spindle Speed | Higher is common | Must be controlled to avoid melting |

| Feed Rate | Geared to tool life | Tuned to chip load & polymer stability |

| Tool Geometry | Standard end mills | Sharp tools, polished flutes for clarity |

| Coolant | Flood / MQL | Air blast / mist to avoid absorption |

| Workholding | Rigid clamping | Pressure-balanced to prevent deformation |

This is why not every “CNC shop” is a plastic cnc machine shop. The tooling strategy must match the material’s characteristics.

Operations Used for CNC Plastic Cutting

- 3-axis & 4-axis milling for profiles, pockets, recesses

- Turning for cylindrical / symmetrical components

- Drilling, tapping, countersinking & thread inserts

- Routing for sheet-based parts and enclosures

- Edge finishing for visibility-grade plastics like PMMA

These operations create machined plastic products that can be tested, assembled, and validated before committing to mass production tooling.

To choose the right machining approach, the next decision is material. That’s where engineered plastics differ dramatically in tolerance, clarity, friction behavior, and machinability.

Not sure which plastic fits your part?

Share your CAD file — we’ll recommend the right material & tolerance.

Plastics Used in CNC Machining (Performance-Based Selection)

Choosing the right plastic is a performance decision — not a price decision. Engineering plastics behave differently under heat, friction, load, and impact. That’s why a cnc machine for plastic must match material properties to the use case, not the other way around.

Performance Comparison: Engineering Plastics for CNC Machining

| Material | Performance Strength | Why It’s Machined | Where It Fits |

|---|---|---|---|

| ABS | Structural strength + stability | Easiest to machine, predictable tolerance | Prototypes, enclosures, housings, brackets |

| Nylon (PA6/PA66) | Wear resistance + low friction | Handles pulleys/gears without lubrication | Automotive internals, robotics, industrial |

| Delrin (POM/Acetal) | Dimensional accuracy + stiffness | Best metal-alternative for tolerance fit | Bushings, spacers, moving parts |

| Polycarbonate (PC) | Impact strength + clarity | Safer alternative to acrylic; high toughness | Guards, covers, load-bearing clear parts |

| Acrylic (PMMA) | Optical clarity + aesthetics | Machined for visibility-grade edge finishes | Displays, lighting diffusers, consumer panels |

| HDPE / UHMWPE | Chemical & abrasion resistance | Doesn’t absorb moisture; machining stable | Medical trays, pharma contact parts, food-grade |

| PEEK (Premium) | High heat + mechanical load | Replaces metal in extreme environments | Aerospace, defense, medical implants |

How to Choose a Plastic by Performance Requirement

| Requirement | Recommended Material | Why |

|---|---|---|

| Best proto-to-production stability | ABS / Delrin | Holds tolerance during revisions |

| Moving parts / friction zones | Nylon / Delrin | Low wear, machine-friendly |

| Transparent & impact resistant | Polycarbonate | Machined clarity + durability |

| Aesthetic visible surface | Acrylic | Polishes to showroom-grade clarity |

| Contact with chemicals / pharma | HDPE / UHMWPE | Non-reactive, stable machining |

| High-temperature environments | PEEK | Metal-replacement performance |

Our plastic cnc machine selection matrix supports OEMs choosing between clarity (Acrylic/PC), durability (Delrin/Nylon), or chemical resistance (HDPE/UHMWPE). This ensures your machined plastic products survive real operating environments instead of just passing prototype review.

Once the material is chosen, the next decision is whether CNC is the right manufacturing method or if the project should shift to 3D printing or molding at scale.

Check if your geometry is machinable before committing to tooling.

Send your model for a free DFM review.

When to Use CNC Plastic Machining vs 3D Printing vs Injection Molding

Not every plastic part should be machined. Some should be printed. Some should be molded.

So the question isn’t “Can CNC make this?” — it’s “Is CNC the most strategic choice right now?”

Decision Matrix: Which Process Fits Your Stage

| Project Stage | Best Process | Why |

|---|---|---|

| Early design iteration | 3D Printing | Fast revisions, low cost |

| Functional prototype / fit & assembly | CNC Plastic Machining | True-to-production behavior |

| Volume scaling (1,000–100,000 units) | Injection Molding | Best long-term cost per part |

Cost & Timeline Logic

- CNC first → validate geometry + confirm tolerances

- Mold later → once design stops changing

This protects budget from premature tooling and avoids the trap of “manufacturing too early.”

Why OEMs Pick CNC Plastics at Pre-Production

- Tolerance matters

- Design isn’t frozen yet

- Real-world behavior > “3D printed similarity”

- Material performance testing required

- Small/medium batches needed fast

How Manufyn Fits Into This

We use CNC machining as the stability bridge:

Prototype → Validation → Pre-production → Molding

so buyers don’t waste tooling money before the design matures.

We position our cnc plastic cutting and machining workflows to help teams stabilize part performance before investing in tooling. That is why global OEMs use Manufyn’s cnc plastic machining services as the pre-tooling validation stage for long-term supply programs.

CNC Plastic Machining Capabilities & Operations

Manufyn’s CNC machining workflow for plastics is built for product teams who need engineering precision before committing to tooling. Our capabilities bridge prototype, validation, and early production, allowing companies to move from CAD to final parts without redesign loops.

Core Operations We Run In-House & Through Global Partners

| Operation | What It Enables | Component Types |

|---|---|---|

| 3-Axis Milling | Profiles, pockets, recesses | Enclosures, brackets, fixtures |

| 4-Axis Machining | Multiple faces without re-clamping | Wheels, pulleys, collars, hubs |

| 5-Axis Machining | Undercuts, organic geometry, curve surfaces | Aerospace plastics, robotics, complex housings |

| Routing (Sheet Plastics) | Large panels, signage, trays, housings | HDPE/PMMA sheets, pharma trays |

| Turning & Facing | Cylindrical precision | Bushings, standoffs, threaded inserts |

| Threading & Tapping | Assembly-ready components | Machine housings, PC/ABS covers |

| Secondary Ops | Assembly, tapping, deburring, polishing | Ready-to-install parts |

This makes our cnc plastic machining services suitable for:

- Rapid prototypes

- Pre-tooling validation batches

- Limited production supply

- Bridge manufacturing before injection molding

Technical Boundaries (What We Say “No” To)

A credible vendor doesn’t accept every job. We decline or redirect when:

- Wall thickness < 0.8mm (risk of flex / melt)

- Unsupported deep pockets (poor chip evacuation)

- Mirror-grade acrylic finish without post-process tolerance (requires polishing)

- Tight tolerance + deep thread combination in soft plastics (requires inserts)

This protects the customer from poor results, redesign costs, and failed builds.

Why This Matters for Buyers

Procurement doesn’t just need a supplier — they need a supplier who knows where CNC works, where it fails, and where molding is smarter.

This is why companies choose Manufyn not for parts, but for production direction.

Our cnc machine for plastic parts is engineered for tolerance stability, while our cnc plastic cutting and routing services stay focused on part flatness, edge quality, and assembly stack-up feasibility.

Once capability aligns, decision-makers ask “Who is this for? Which industries actually use it?” That leads into the next section.

Industries & Applications Using CNC Machined Plastic Parts

CNC machining is not only for prototypes; it is a validated supply chain method for industries that need performance plastics to replace metal, reduce weight, and shorten development timelines.

Who Buys CNC Plastic Machining & Why

| Industry | Why They Use Plastics Instead of Metal | Typical Parts Ordered |

|---|---|---|

| Automotive & EV | Weight reduction, fast proto → SOP | Connectors, brackets, bushings, interior modules |

| Medical & Pharma | Chemical safe, non-reactive, easy sterilization | Trays, valve blocks, test fixtures, HDPE/PP components |

| Aerospace & Defense | Lightweight + stability during vibration | Polycarbonate covers, clamps, routing panels |

| Robotics & Automation | Low friction + repeatability in movement | Gears, wear pads, motion plates, POM/Delrin guides |

| Consumer Products & Electronics | Fast-to-market proto + enclosure builds | Housings, displays, acrylic UI windows, spacers |

| Industrial / OEM | Functional replacement before tooling approval | Pulleys, manifolds, couplers, mounting plates |

These categories aren’t guesses — they’re the ordering behavior of companies validating design before investing in tooling.

Why These Industries Don’t Start With Injection Molding

- Design is not frozen yet

- Dimensions still change after field test

- Tooling cost is not justifiable at early stage

- They need 25–500 units, not 50,000+

- CNC supports EVT → DVT → PVT → Molding handoff

So CNC machining is the bridge between prototype and stable supply.

Working in Automotive, Medical, Aerospace or Robotics?

We’ll validate performance for your industry environment.

Tolerances, QA Workflow & Surface Finish Standards

Tolerances define whether a part fits, not whether it’s “machined well.” In plastics, tolerance stability depends on heat, chip load, wall thickness, and material choice — which is why machining plastics is not interchangeable with machining metals.

Manufyn machines most plastics between ±0.01mm to ±0.05mm, depending on part geometry and performance requirement. For assemblies, we review tolerance stack-up during RFQ to prevent compounded deviation across mating features.

Practical Tolerance Expectations by Material

| Material | Typical Tolerance | Why It Varies |

|---|---|---|

| ABS | ±0.05 mm | Low melt point; needs controlled tooling |

| Nylon / PA6 | ±0.05 – 0.10 mm | Absorbs moisture; moves slightly post-machining |

| Delrin / POM | ±0.01 – 0.03 mm | Most dimensionally stable for precision |

| Acrylic / PMMA | ±0.05 mm | Heat sensitivity + optical finish requirements |

| Polycarbonate | ±0.03 – 0.05 mm | Impact strength holds tolerance, clarity processing |

| HDPE / UHMWPE | ±0.10 mm | Soft material; suitable for non-critical dimensions |

| PEEK | ±0.02 mm | High-precision alternative to lightweight metals |

If a tolerance request challenges material behavior, we tell the buyer upfront — not after machining.

QA & Inspection Flow at Manufyn

- DFM review before accepting order

- Critical-to-function features flagged

- Cutting strategy defined → feed, speed, tool, coolant

- CMM, caliper & gauge measurements as required

- Batch traceability for recurring orders

For optical materials like Acrylic or Polycarbonate, surface finish is handled as a separate specification — machining alone cannot deliver a showroom gloss without post-processing. We recommend polishing processes after tolerance confirmation.

This ensures your machined plastic products arrive assembly-ready, with tolerance expectations aligned to material behavior — not theory.

Tolerance-critical features?

Let’s confirm stack-up before production.

RFQ Requirements, Pricing Logic & How We Quote

A successful RFQ is not about “sending a drawing.” It’s about eliminating ambiguity so pricing reflects manufacturability, not revision cost.

To quote cnc plastic machining services accurately, we need clarity on design intent and performance priorities.

What to Send For a Fast, Accurate Quote

| Required | Why |

|---|---|

| 3D CAD (STEP/IGES/SLDPRT) | Defines manufacturability & toolpath strategy |

| 2D Drawing (if tolerance-critical) | Prevents assumption errors |

| Material Selection | Recommends correct cutter & chip load |

| Quantity Range | Prototype, bridge, or production pricing |

| Surface Finish Requirement | Determines post-processing investment |

| Assembly Fitment Notes | Prevents tolerance conflict with mating parts |

Optional but Helpful

- End-use environment (heat, load, chemical contact)

- Annual volume expectation (planning pre-molding path)

- If molding is planned later (tool-readiness strategy)

How Pricing Is Calculated

Pricing for a cnc machine for plastic parts depends on:

- Material cost + accessible stock format

- Machine time (axis complexity + operations count)

- Tooling strategy (sharp tools, polymer aggression control)

- Surface finish / post-process

- Recurrence (repeat orders reduce per-unit cost)

This is why a part can cost:

- ₹800–₹2,500 as a prototype

- ₹300–₹950+ in early production

- ₹120–₹350 at molding scale (post-CNC validation)

CNC machining is not the final step — it’s the stability step.

Our RFQ workflow for cnc plastic cutting and plastic machining ensures the quote reflects manufacturability, not assumptions — reducing redesign loops and accelerating product launch.

Scaling from CNC Plastic Machining to Injection Molding

CNC machining is not the end goal for most OEMs — it’s the validation stage before locking design and investing in tooling. The purpose is to stabilize dimensions, confirm assembly fit, and validate performance before committing to molds.

How the Transition Works

| Stage | Purpose | Output |

|---|---|---|

| EVT (Engineering Validation) | Check function + design feasibility | CNC parts, no tooling |

| DVT (Design Validation) | Lock geometry & assembly fitment | CNC for tolerance proofing |

| PVT (Production Validation) | Confirm repeatability & supplier quality | CNC for early batches or bridge supply |

| Mass Production | Tooling + scale | Injection molding if volume justifies cost |

CNC machining is the bridge between CAD and mass manufacturing. When design stops changing, we shift to molding.

When CNC Should Be Used Instead of Molding

- When yearly demand is < 7,500–10,000 units

- When assembly fitment is not yet validated

- When tolerance stack-up needs proof

- When functional testing requires multiple revisions

- When investor approval is pending before tooling

When Molding Becomes Smarter

- Dimensions are frozen for 60+ days

- MOQ justifies tool amortization

- Per-unit cost must drop for retail pricing

- Product enters recurring demand cycle

Manufyn helps buyers avoid premature tooling — the number one cause of rework cost in early-stage product development.

This staged approach ensures machined plastic products become the functional baseline for injection tooling, rather than a risky starting point.

Request a Quote for CNC Plastic Machining

Share CAD files → get feasibility, DFM notes, and pricing.