Injection molding is one of the most widely used manufacturing methods, enabling the production of complex, durable, and cost-efficient parts at scale. From automotive to consumer electronics, the application of injection moulding spans almost every industry that requires precision and repeatability.

The process has evolved far beyond standard molding, with advanced techniques like overmolding, gas-assisted molding, and micro molding offering greater flexibility for manufacturers. Among the most common engineered materials, pc abs injection moulding is highly popular for producing strong yet lightweight components for electronics and vehicles.

As industries demand greater efficiency, compliance, and custom solutions, understanding the different moulding form options is essential to selecting the right manufacturing approach.

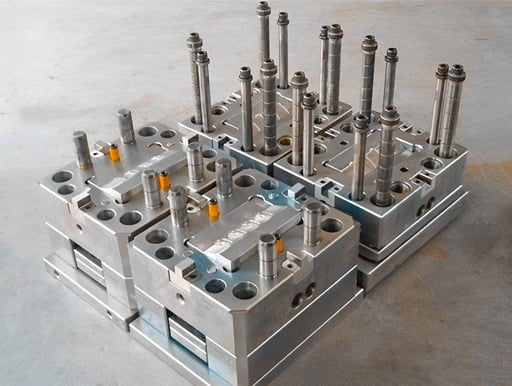

Standard Injection Molding Process

At its core, injection molding is a simple yet powerful process. Molten plastic is injected into a mold cavity, cooled, and ejected in the desired shape. This moulding form creates consistent, repeatable parts, making it ideal for mass production.

Globally, the process is known not only in English but also in other languages — for example, moldeo in Spanish. This reflects the worldwide adoption of injection molding as the backbone of manufacturing industries.

While standard injection molding offers reliability and cost-effectiveness, it comes with limitations when dealing with multi-material products, large parts, or intricate assemblies. These limitations have led to innovations such as overmolding, insert molding, and gas-assisted injection molding.

Overmolding and Insert Molding: Adding Strength and Functionality

One of the most common applications of injection moulding is combining multiple materials or components into a single finished part. Two specialized techniques — overmolding and injection moulding inserts — allow manufacturers to achieve this with precision.

Overmolding

Overmolding is the process of molding one material directly over another, such as adding a soft grip over a rigid plastic handle. This technique enhances ergonomics, durability, and product appeal. For example, in pc abs injection moulding, the rigid PC/ABS base can be combined with softer elastomers to deliver a sturdy yet comfortable component.

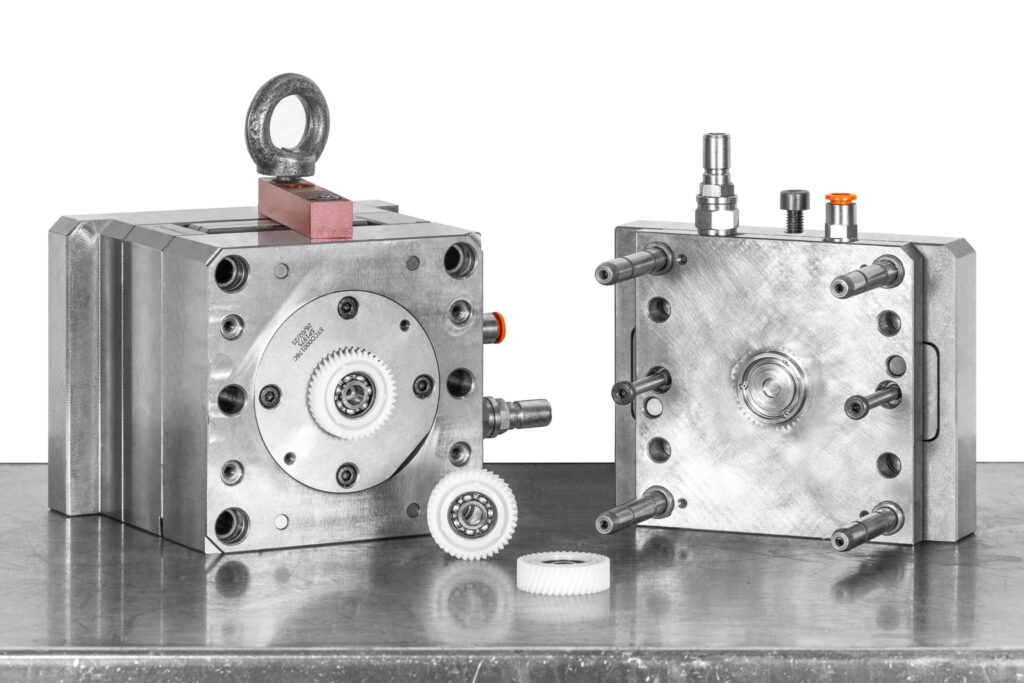

Insert Molding

Insert molding, on the other hand, involves placing pre-formed components (such as metal fasteners, electronic connectors, or threaded parts) into the mold before injecting plastic around them. The result is a robust assembly where the insert and the plastic body form a single, reliable unit.

Design Considerations

Both methods benefit from careful injection moulding analysis, ensuring proper bonding between materials, optimized gate design, and reduced risks of jetting in injection moulding. By conducting in-depth simulations and prototyping, manufacturers can predict material flow, shrinkage, and stress points before starting production.

Together, overmolding and insert molding expand the versatility of moulding form techniques, supporting industries such as automotive, aerospace, consumer electronics, and precision agriculture.

Gas-Assisted & Structural Foam Molding: Reducing Weight, Boosting Efficiency

In advanced applications of injection moulding, manufacturers often look for ways to reduce material use, lower part weight, and enhance structural performance. Two techniques that achieve these goals are gas-assisted molding and structural foam molding.

Gas-Assisted Injection Molding

This method introduces pressurized nitrogen gas into the molten plastic during the injection moulding procedure. The gas creates hollow channels inside the part, reducing weight and preventing surface issues such as jetting in injection moulding. Commonly used in automotive interiors, furniture, and appliance housings, this technique ensures high strength-to-weight ratios while minimizing material waste.

Structural Foam Molding

Structural foam molding uses a foaming agent to form a microcellular core inside the plastic. The outer surface remains solid, but the inner foam reduces density, improving insulation and rigidity. It’s widely applied in heavy industry, construction equipment, and large-panel production.

Key Advantages

- Lower material costs and weight

- Improved dimensional stability

- Elimination of sink marks and warpage

- Better surface finish with reduced injection moulding faults

Both processes require optimized machine settings and proper injection moulding lube selection to ensure smooth operation and consistent part quality.

Together, gas-assisted and structural foam molding showcase how moulding form innovations continue to transform industries, especially where lightweight yet durable parts are critical.

Specialty Applications: From PC/ABS to Aerospace Standards

While traditional plastics dominate most markets, modern industries increasingly require specialized materials and compliance with global standards. Advanced applications of injection moulding cover everything from tough engineering blends to aerospace-grade components.

PC ABS Injection Moulding

PC/ABS is a high-performance plastic blend combining the strength of polycarbonate with the flexibility of ABS. PC ABS injection moulding is widely used in automotive interiors, medical housings, and consumer electronics where impact resistance, heat stability, and aesthetic finish are critical.

Injection Moulding of Ceramics

Beyond plastics, injection moulding of ceramics enables the production of complex, high-temperature-resistant parts. Ceramics are essential for aerospace turbines, defense applications, and electronics, where metals or polymers cannot withstand extreme environments.

AS EN 9100 Injection Moulding for Aerospace

For aerospace and defense, compliance is non-negotiable. AS EN 9100 injection moulding ensures that parts meet strict international standards for quality and traceability. From lightweight brackets to structural inserts, aerospace manufacturers depend on suppliers certified under this benchmark.

Global Reach – From Vancouver to Emerging Markets

Specialty molding is not confined to one geography. Companies sourcing injection moulding vancouver services or exploring moldeo (the Spanish term for molding) in Latin America all face the same challenge: finding certified partners capable of delivering quality. Platforms like Manufyn help global buyers connect with reliable suppliers across regions.

By combining advanced materials, stringent standards, and global sourcing options, these specialty techniques represent the most sophisticated side of moulding form technology.

Emerging Innovations: Prototyping, Injection Film & Future Trends

The field of injection molding continues to evolve, with innovations that expand design possibilities and reduce time-to-market. These new approaches showcase the versatility of applications of injection moulding across industries.

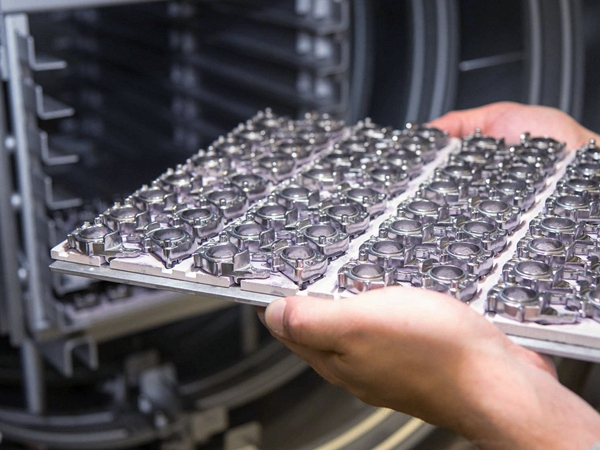

Injection Moulding Prototypes

Before mass production, creating injection moulding prototypes allows engineers to validate part design, test materials, and minimize injection moulding faults. Rapid prototyping reduces the risk of costly errors and shortens product development cycles.

Injection Film Technology

An exciting innovation is injection film, where thin decorative or functional films are integrated into the molding process. This technique enhances surfaces with textures, colors, or electronic functions, commonly applied in automotive interiors, consumer devices, and medical equipment.

Sustainability & Smart Materials

Advanced materials like bio-plastics, recycled resins, and PU blends (as in pu injection moulding) are shaping a more sustainable future. These innovations allow businesses to balance durability with environmental responsibility.

Manufyn’s Role in Driving Innovation

At Manufyn, we help businesses adopt cutting-edge injection molding processes — from pc abs injection moulding to injection moulding of ceramics — by connecting them with certified, global suppliers. Whether you’re exploring injection moulding vancouver, moldeo in Latin America, or sourcing from Asia, our platform ensures quality, compliance, and cost efficiency.

By investing in injection moulding analysis and advanced techniques, manufacturers can achieve defect-free production and bring innovative products to market faster.

Why Choose Manufyn for Advanced Injection Moulding Solutions?

At Manufyn, we go beyond standard injection moulding services by combining innovation, precision, and global expertise. Our solutions are trusted across industries — from aerospace and automotive to consumer electronics and heavy machinery. Whether you need PC ABS injection moulding for durable components, injection moulding inserts for stronger assemblies, or niche techniques like injection film moulding, our team ensures defect-free, production-ready results.

With a strong focus on quality, scalability, and cost-efficiency, we support businesses worldwide — from local hubs like injection moulding Vancouver to large-scale global sourcing projects. Our engineers leverage advanced injection moulding analysis to detect and eliminate potential issues like jetting, flow lines, or warpage before mass production, saving clients valuable time and resources.

As a manufacturing partner, Manufyn is committed to delivering:

- AS EN 9100-certified processes for aerospace and defence.

- End-to-end services including prototyping, testing, and large-volume production.

- Expertise in modern materials such as PU, ceramics, and engineered plastics.

- Sustainable practices and innovative moulding form designs.

With Manufyn, you don’t just get parts — you get a reliable, future-ready manufacturing partner who ensures high-quality injection moulding with zero compromises.

Conclusion: Choosing the Right Partner for Advanced Injection Molding

From overmolding and injection moulding inserts to gas-assisted molding, pc abs injection moulding, and injection moulding of ceramics, the applications of injection molding are vast and transformative. Each technique solves unique challenges, whether reducing weight, improving durability, or meeting strict standards like AS EN 9100 injection moulding for aerospace.

Preventing injection moulding faults begins with the right design, materials, and supplier expertise. By leveraging innovations such as injection film, sustainable PU blends, and global sourcing networks — from injection moulding vancouver to emerging markets where moldeo is growing — companies can stay ahead in competitive industries.

Partner with Manufyn for Reliable Global Manufacturing

At Manufyn, we simplify sourcing by connecting you with certified, reliable manufacturers skilled in every aspect of injection molding. From injection moulding prototypes to full-scale production, our managed platform ensures compliance, quality, and cost efficiency.

Ready to scale your next project? Request a Free Consultation today and discover how Manufyn can streamline your manufacturing journey.

FAQs on Applications of Injection Moulding

Injection moulding is used across automotive, aerospace, electronics, and consumer goods. From producing durable PC ABS injection moulding components to high-precision medical devices, its applications are vast due to accuracy, repeatability, and cost-efficiency.

PC ABS injection moulding combines the toughness of polycarbonate with the flexibility of ABS. It offers heat resistance, impact strength, and is widely used in automotive and electronic housings.

Jetting in injection moulding is a common defect where molten plastic shoots into the cavity, creating snake-like flow marks. It occurs due to high injection speed or improper gate design. Optimized moulding form and injection moulding analysis can prevent jetting.

Injection moulding inserts reinforce parts with threaded metal or plastic inserts during production. This ensures stronger assembly, durability, and reduces secondary operations.

Injection moulding lube reduces friction, prevents sticking, and improves mould release. It also extends tool life, lowers cycle time, and maintains consistent part quality.

AS EN 9100 injection moulding standards ensure aerospace-grade quality control. Manufacturers meeting these certifications deliver high-precision moulded parts with zero defects.

Injection moulding analysis simulates flow, cooling, and warpage before production. It helps avoid common issues like jetting, voids, and weld lines, saving costs on faulty moulds.

Moldeo refers to the moulding process in Spanish. In global sourcing, moldeo-based injection moulding highlights how the technique is widely adopted across international markets, including injection moulding Vancouver and beyond.

Injection film moulding is a process where decorative or functional films are inserted into the mould before injection. It creates aesthetic, scratch-resistant, or branded surfaces without secondary finishing.

Manufyn delivers end-to-end solutions, from prototyping to production. With expertise in applications like PC ABS injection moulding, inserts, and injection film, we help businesses scale globally with high-quality, defect-free moulding services.