Industrial robot manufacturing services are no longer limited to large OEMs with massive in-house facilities. As demand for industrial automation grows across automotive, electronics, logistics, and warehousing, companies are increasingly evaluating whether to manufacture robots in-house (OEM model) or partner with contract manufacturing services.

For US-based companies, this decision directly impacts cost, speed to market, scalability, and IP control. Choosing the wrong manufacturing model can delay product launches, inflate costs, or restrict growth.

In this guide, we break down OEM vs contract manufacturing for industrial robots, explain how industrial robot manufacturing services work, and help you identify the best path based on your business stage and production goals.

Planning to manufacture or scale an industrial robot? See which manufacturing model fits your product.

What Are Industrial Robot Manufacturing Services?

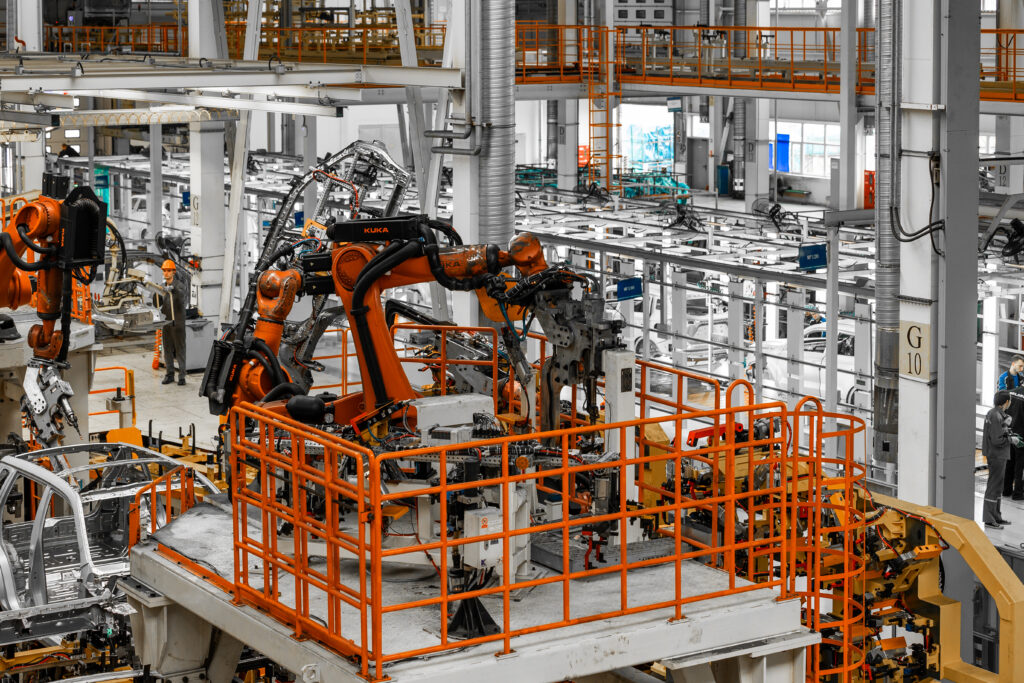

Industrial Robot Manufacturing Services refer to specialized, end-to-end production capabilities used to build industrial robots at prototype, pilot, and commercial scale. These services are typically used by robotics OEMs, automation companies, and system integrators that want to focus on product innovation while relying on manufacturing partners for execution.

Unlike generic electronics or mechanical manufacturing, industrial robot manufacturing combines multiple complex disciplines—precision mechanics, electronics, motion control, software integration, and compliance testing—within a single production workflow.

Core Components of Industrial Robot Manufacturing Services

1. Design for Manufacturing (DFM) & Engineering Support

Manufacturing partners work with your engineering team to:

- Optimize robot designs for manufacturability and assembly

- Improve component standardization

- Reduce part count and production risk

- Ensure scalability from prototype to volume production

This phase is critical in avoiding redesigns once production begins.

2. Prototyping, Pilot Builds & Validation

Industrial robot manufacturing services often support:

- Alpha and beta prototypes

- Functional and load testing

- Small pilot runs to validate assembly processes

- Pre-certification testing before commercial rollout

This allows companies to identify design or supply chain issues early.

3. Component Sourcing & Supply Chain Coordination

Robotics manufacturing requires access to:

- Servo motors, actuators, gearboxes

- Controllers, sensors, wiring harnesses

- Precision-machined and fabricated structures

Manufacturing partners manage supplier qualification, lead times, cost control, and risk mitigation, which is especially important for globally sourced components.

4. Assembly, Integration & System Calibration

This includes:

- Mechanical and electrical assembly

- Firmware and control system integration

- Calibration for precision, repeatability, and payload performance

- Functional testing under real-world operating conditions

Consistency at this stage directly impacts product reliability in the field.

5. Quality Assurance, Compliance & Certifications

Industrial robot manufacturing services typically support:

- ISO-based quality processes

- Safety and performance testing

- Documentation for CE, UL, or other regional compliance

- Traceability and production records for audits

Compliance readiness is often a deciding factor for enterprise buyers.

6. Production Scaling & Global Fulfillment

As demand grows, manufacturing services enable:

- Low-volume to mass-production scaling

- Production line optimization

- Packaging, labeling, and export documentation

- Global logistics and delivery coordination

This allows companies to scale without building new facilities.

Why Companies Use Industrial Robot Manufacturing Services

Companies use industrial robot manufacturing services to:

- Reduce upfront capital investment

- Shorten development and launch timelines

- Access specialized manufacturing expertise

- Scale production without operational overload

This makes such services particularly attractive for startups, growth-stage robotics companies, and OEMs expanding into new markets.

Have a robot design or production plan in mind? Get clarity on manufacturing feasibility, cost, and scale options.

OEM vs Contract Manufacturing in Industrial Robotics

When evaluating industrial robot manufacturing services, most companies narrow their options down to two models: OEM (in-house) manufacturing or contract manufacturing. While both approaches can produce high-quality industrial robots, they differ significantly in cost structure, operational complexity, speed, and scalability.

Understanding these differences early helps avoid expensive pivots later in the product lifecycle.

What Is OEM (In-House) Manufacturing?

In the OEM model, the company owns and operates its manufacturing infrastructure. This includes production facilities, machinery, supply chains, quality systems, and manufacturing teams.

OEM manufacturing typically involves:

- Dedicated production lines

- Internal sourcing and supplier management

- Full control over processes and IP

- High upfront investment in CapEx and staffing

This model is often chosen by large, established robotics companies with predictable volumes.

What Is Contract Manufacturing?

Contract manufacturing involves outsourcing part or all of the production process to a specialized manufacturing partner that already has the infrastructure, workforce, and supplier ecosystem in place.

In industrial robotics, contract manufacturers may handle:

- Prototyping and pilot builds

- Component sourcing and sub-assemblies

- Full robot assembly and testing

- Quality assurance and compliance documentation

- Scale production and global fulfillment

This model allows companies to stay asset-light while scaling faster.

OEM vs Contract Manufacturing – Key Differences

| Failure | Root Cause | Business Impact |

|---|---|---|

| Part damage during ejection | Zero or insufficient draft on undercuts | Scrap and rework |

| Side action seizure | Overuse or poor alignment | Mold downtime |

| Excessive mold wear | Too many moving components | High maintenance cost |

| Long cycle times | Multiple undercut mechanisms | Reduced throughput |

| Cost overruns | Late tooling decisions | Tool redesign and delays |

Not sure which manufacturing model fits your robot? Get an expert evaluation based on your product and volume plans.

OEM Manufacturing in Robotics– Pros, Cons & When It Makes Sense

OEM manufacturing can be a strong choice in specific scenarios, but it also comes with operational trade-offs that many robotics companies underestimate.

Advantages of OEM Manufacturing in Robotics

- Full Control Over Production

Complete oversight of manufacturing processes, quality standards, and supply chain decisions. - IP & Process Ownership

Easier control over proprietary manufacturing techniques and sensitive designs. - Long-Term Cost Efficiency at Scale

At very high, stable volumes, per-unit costs can be optimized over time. - Deep Manufacturing Customization

Greater flexibility to tailor processes to highly specialized robot designs.

Limitations of OEM Manufacturing in Robotics

- High Capital Investment

Facilities, equipment, skilled labor, and compliance systems require substantial upfront spend. - Longer Time to Market

Setting up production lines and supplier ecosystems takes time. - Scaling Challenges

Sudden demand spikes can strain in-house capacity. - Operational Distraction

Engineering and leadership time shifts from innovation to manufacturing execution.

When OEM Manufacturing Makes Sense

OEM manufacturing is typically the right choice when:

- Production volumes are consistently high and predictable

- The company has long-term capital commitment

- Manufacturing is a core competitive advantage

- There is strong in-house expertise in robotics production

For many emerging and mid-size robotics companies, however, these conditions are not met early on.

Assess whether OEM manufacturing is viable for your industrial robot before committing capital.

Contract Manufacturing for Industrial Robots – Benefits & Limitations

Contract manufacturing has become the preferred model for many robotics companies using industrial robot manufacturing services, especially those looking to scale efficiently without heavy capital investment.

Instead of building production capabilities from scratch, companies partner with manufacturing specialists who already have robotics-ready infrastructure, supplier networks, and quality systems in place.

Key Benefits of Contract Manufacturing in Industrial Robotics

- Faster Time to Market

Existing production lines, trained teams, and supplier ecosystems significantly reduce setup time. - Lower Capital Risk

Companies avoid large upfront investments in facilities, equipment, and compliance systems. - Production Flexibility

Easily scale from prototypes to pilot runs to volume production based on demand. - Access to Specialized Capabilities

Robotics manufacturing requires precision machining, electronics integration, and motion-control expertise—often difficult to build internally. - Global Supply Chain Access

Contract manufacturers provide access to a broader supplier base, helping optimize cost and lead times.

At Manufyn, contract manufacturing for industrial robots is supported through a verified network of robotics-capable manufacturers, enabling companies to move from concept to production without managing multiple vendors directly.

Limitations of Contract Manufacturing (And How to Mitigate Them)

- Reduced Direct Control

Mitigated through audits, quality agreements, and process transparency. - IP Protection Concerns

Addressed via NDAs, controlled data access, and segmented production workflows. - Dependency on External Partners

Reduced by multi-supplier strategies and clear escalation mechanisms.

Manufyn helps mitigate these risks by acting as a single accountability layer—overseeing supplier selection, quality assurance, and production coordination.

Explore contract manufacturing options for your industrial robot with vetted partners.

Cost Comparison – OEM vs Contract Manufacturing

Cost is one of the most decisive factors when choosing between OEM and contract-based industrial robot manufacturing services, but many companies focus only on per-unit pricing while overlooking structural costs.

Cost Components in OEM Manufacturing

- Facility setup and maintenance

- Capital equipment and tooling

- Manufacturing and QA teams

- Supplier onboarding and management

- Compliance, audits, and certifications

These costs are largely fixed and must be absorbed regardless of production volume.

Cost Components in Contract Manufacturing

- Per-unit manufacturing cost

- Tooling and setup fees (often amortized)

- Quality and compliance services

- Supply chain coordination

- Logistics and export support

This model shifts costs from fixed CapEx to variable OpEx, improving cash flow and flexibility.

OEM vs Contract Manufacturing – Cost Impact Summary

| Cost Aspect | OEM Manufacturing | Contract Manufacturing |

|---|---|---|

| Upfront Investment | Very High | Low |

| Cost Flexibility | Low | High |

| Break-even Volume | High | Lower |

| Financial Risk | Higher | Lower |

For companies evaluating multiple manufacturing paths, Manufyn provides cost modeling support—helping compare OEM vs contract manufacturing scenarios based on product complexity, volumes, and market demand.

Get a cost comparison for your industrial robot manufacturing plan.

How to Choose the Right Industrial Robot Manufacturing Services Partner

Selecting the right partner for industrial robot manufacturing services is not just a sourcing decision—it directly impacts product quality, timelines, compliance, and long-term scalability.

When evaluating potential manufacturing partners, companies should assess the following critical factors:

1. Robotics-Specific Manufacturing Experience

Not all manufacturers are equipped to build industrial robots. Look for experience in:

- Precision mechanical assemblies

- Motion control and actuation systems

- Electronics integration and wiring

- Robotics testing and calibration

2. Quality Systems & Compliance Readiness

Your manufacturing partner should support:

- ISO-based quality management systems

- Safety and performance testing

- Documentation for CE, UL, or regional certifications

- Traceability and audit readiness

3. Scalability & Production Flexibility

Ensure the partner can:

- Support low-volume pilot runs

- Scale to commercial production

- Adapt to demand fluctuations without disruption

4. IP Protection & Data Security

Manufacturing agreements should include:

- Clear NDAs and IP ownership clauses

- Controlled access to sensitive design data

- Segmented production workflows where needed

5. Supply Chain & Component Sourcing Capability

A strong partner manages:

- Supplier qualification and redundancy

- Cost optimization without quality compromise

- Lead-time risk mitigation

Manufyn simplifies this process by pre-vetting industrial robot manufacturing partners and aligning them with your technical, commercial, and compliance requirements—saving months of trial-and-error.

Get matched with a manufacturing partner suited to your industrial robot.

Why Companies Choose Manufyn for Industrial Robot Manufacturing Services

Companies using industrial robot manufacturing services often struggle with fragmented supplier ecosystems, inconsistent quality, and lack of accountability. Manufyn was built to solve these exact challenges.

How Manufyn Adds Value

- Verified Manufacturing Network

Access to vetted manufacturers experienced in robotics, automation, and precision engineering. - Single Point of Accountability

One partner managing supplier coordination, production tracking, and quality oversight. - Cost & Feasibility Analysis

Clear cost models and manufacturability assessments before production begins. - Quality Assurance & Audits

Ongoing quality checks to ensure consistency across batches and locations. - Scalable Global Manufacturing

Support for prototyping, pilot runs, and volume production with export readiness.

Whether you’re a startup validating your first industrial robot or an established OEM scaling production, Manufyn enables faster, lower-risk manufacturing execution.

Submit Your Industrial Robot Manufacturing Requirement

FAQs – Industrial Robot Manufacturing Services

Industrial robot manufacturing services include the end-to-end process of designing, producing, assembling, testing, and scaling industrial robots through specialized manufacturing partners. These services cover prototyping, component sourcing, assembly, quality assurance, compliance, and volume production for robotics OEMs and automation companies.

OEM manufacturing involves producing industrial robots in-house using owned facilities and teams, while contract manufacturing outsources production to specialized partners. OEM offers higher control but requires significant capital investment, whereas contract manufacturing provides faster scaling, lower upfront costs, and greater production flexibility.

Yes, contract manufacturing is widely used for industrial robots, especially by startups and growth-stage companies. Specialized manufacturers have the infrastructure and expertise required for precision mechanics, electronics integration, and robotics testing, making contract manufacturing a scalable and cost-effective option.

Industrial robot manufacturing costs depend on factors such as robot complexity, production volume, component sourcing, compliance requirements, and manufacturing model. OEM manufacturing has high upfront costs, while contract manufacturing converts most expenses into per-unit costs, making budgeting more predictable at lower volumes.

Yes, many industrial robot manufacturing services support low-volume and pilot production. This is common during product validation, market testing, or early commercialization, allowing companies to scale production gradually without committing to large manufacturing investments upfront.

IP protection is managed through NDAs, clear ownership clauses, controlled access to design data, and segmented manufacturing workflows. Working with vetted manufacturing partners and having strong contractual agreements significantly reduces IP risk in contract robot manufacturing.

Manufacturing timelines vary based on design maturity, component availability, and production volume. Prototype builds may take a few weeks, while pilot and commercial production can take several months. Contract manufacturing typically shortens timelines by using existing infrastructure and supplier networks.

Industrial robot manufacturing services are commonly used in automotive, electronics, warehousing and logistics, metal fabrication, packaging, and industrial automation. These services support both standard industrial robots and custom automation solutions.

Common certifications include ISO quality standards and safety or compliance requirements such as CE or UL, depending on the target market. Manufacturing partners often assist with testing, documentation, and audit readiness to meet regional and industry-specific regulations.

Companies should evaluate robotics manufacturing experience, quality systems, compliance capability, scalability, IP protection measures, and supply chain strength. Many businesses use platforms like Manufyn to access pre-vetted manufacturing partners and reduce sourcing risk.

Ready to Manufacture or Scale Your Industrial Robot?

If you’re evaluating industrial robot manufacturing services and deciding between OEM and contract manufacturing, Manufyn can help you move forward with clarity.

Conversion Actions:

- Request a manufacturing consultation

- Get a cost comparison

- Submit an RFQ