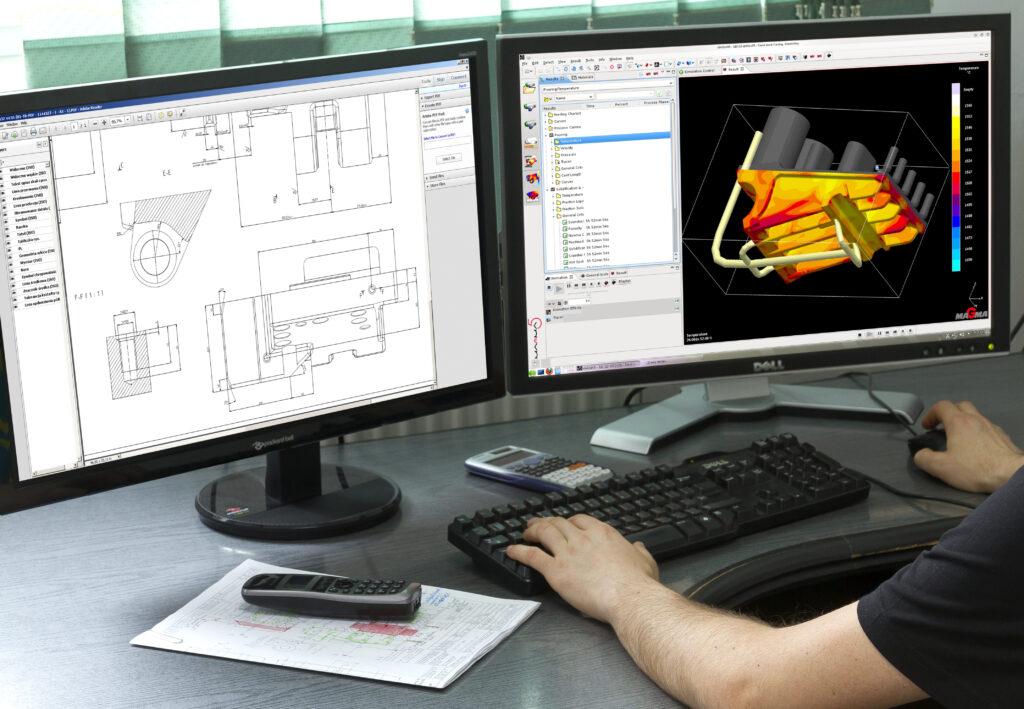

CAE (Computer-Aided Engineering) Services for High-Performance Product Design

Advanced CAE Engineering & Simulation for Manufacturing Success

Manufyn offers robust CAE engineering services that empower your product development process with simulation-driven design, optimization, and validation. Our team leverages industry-leading computer-aided engineering (CAE) software to identify performance challenges early, reduce prototyping costs, and enhance product reliability before physical production begins.