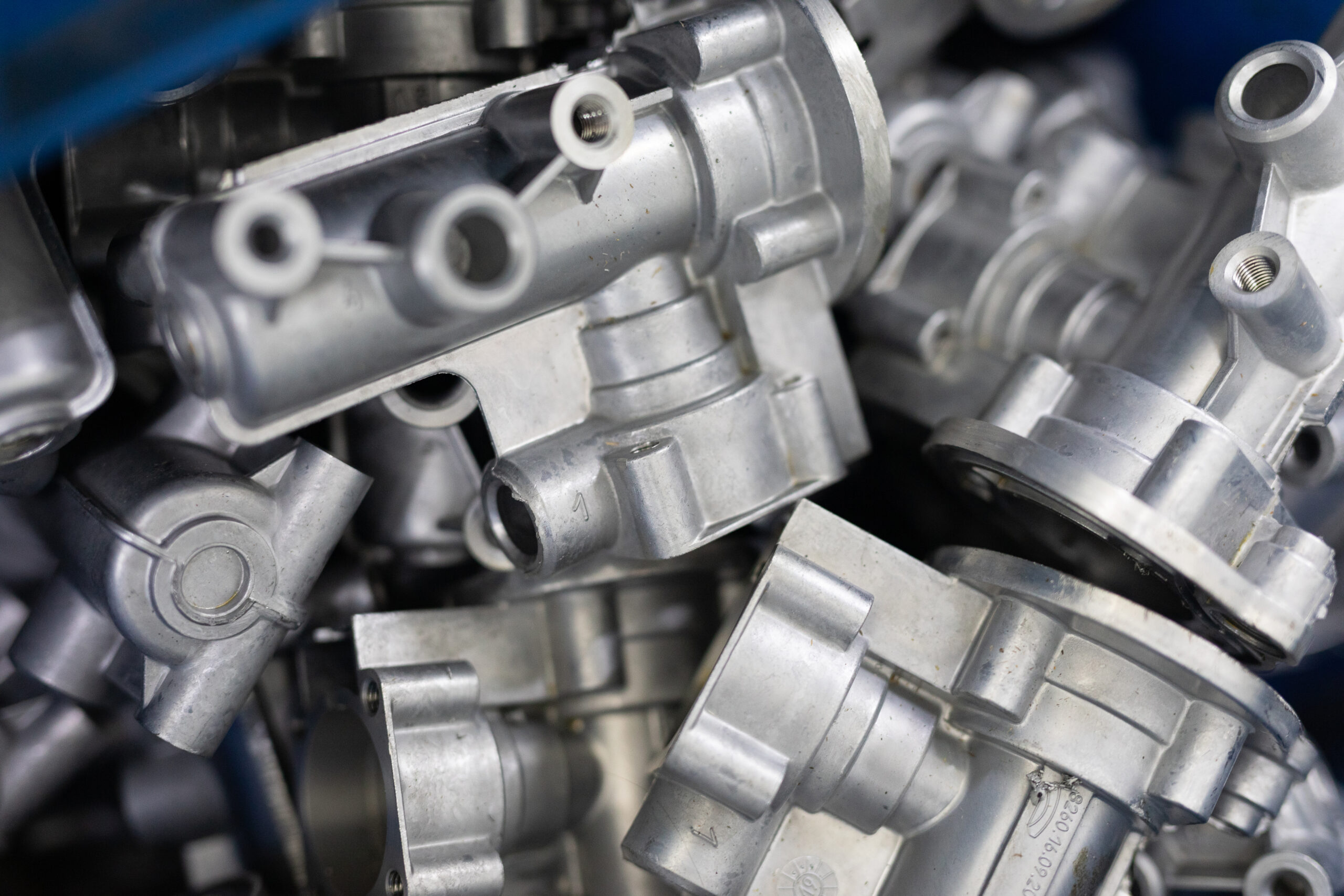

Casting

Manufyn caters to Steel as well as Aluminium alloys with all types of casting processes. Our state of the art machine shops are capable of producing parts with narrow tolerances.

Casting and forging are two distinct metal shaping processes used in manufacturing to create a wide range of metal components. Each process has its own advantages, applications, and considerations. Manufyn caters to all types of Ferrous and Non-ferrous metals and all types of casting processes, from batch production to mass production.

Casting vs. Forging:

Both casting and forging processes have their merits and are chosen based on factors like component design, material properties, production volume, and cost considerations.

- Strength: Forged parts generally have better mechanical properties and strength due to the deformation process that aligns the grain structure.

- Complexity: Casting allows for complex shapes and intricate details, while forging is better suited for simpler shapes and stronger components.

- Material Usage: Casting can create more intricate designs with less material wastage, while forging often results in material loss due to trimming.

- Surface Finish: Forged parts tend to have a better surface finish compared to cast parts.

- Cost: Casting is generally more cost-effective for complex shapes and larger quantities, while forging can be more economical for simpler parts and smaller quantities.

- Sand Casting: In sand casting, a mold is created by compacting specially prepared sand around a pattern of the desired part. The molten metal is then poured into the mold cavity. After solidification, the mold is broken apart to reveal the casting.

- Investment Casting: Also known as lost-wax casting, this process involves creating a wax pattern, coating it with a ceramic shell, and then melting the wax out to leave a cavity. Molten metal is poured into the cavity, and once cooled, the ceramic shell is broken away to reveal the casting.

- Die Casting: Die casting is used for producing intricate and geometrically complex parts. Molten metal is forced into a mold cavity at high pressure. After solidification, the mold is opened, and the casting is ejected.

- Permanent Mold Casting: Similar to die casting, permanent mold casting uses reusable molds made from materials like steel or cast iron. Molten metal is poured into the mold, and after solidification, the mold is opened to release the casting.

Commodities

Brochures

View our 2023 brochure for an easy to read guide on all of the services offer.