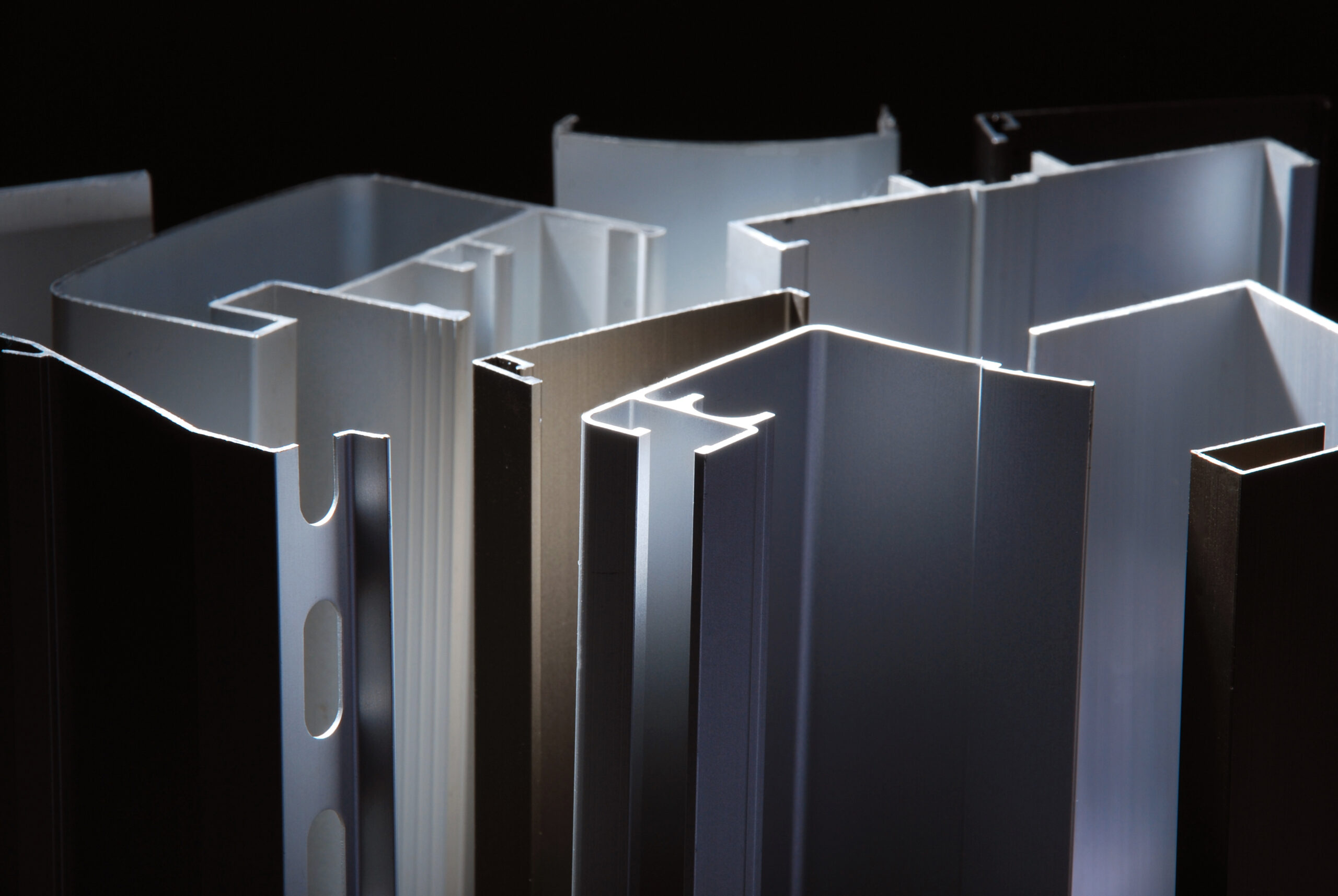

Aluminium Extrusion

Manufyn caters to all compositions of Aluminium alloys and supplies extrusion profiles of customised shapes and sizes as per requirement. Cutting, Surface finishing such as brushing, polishing, anodizing, or powder coating is done to enhance appearance, corrosion resistance, and durability as per customer specifications.

Aluminum extrusion involves shaping aluminum alloy billets into various profiles, and the choice of aluminum alloy grade depends on the specific requirements of the application. Different alloy grades offer varying combinations of mechanical properties, corrosion resistance, formability, and other characteristics. Here are some common aluminum alloy grades used for extrusion:

1. Alloy 6063:

- This is one of the most widely used alloys for extrusion due to its good combination of strength, formability, and surface finish.

- It’s commonly used for architectural applications, window frames, door frames, curtain walls, and other structural components.

- Alloy 6063 can be easily anodized, providing enhanced corrosion resistance and decorative finishes.

2. Alloy 6061:

- Alloy 6061 offers good strength and excellent machinability.

- It’s used for a wide range of applications, including structural components, industrial profiles, and parts requiring both strength and corrosion resistance.

- Alloy 6061 can be heat treated to achieve higher mechanical properties.

3. Alloy 6082:

- Similar to 6061, alloy 6082 offers good strength and corrosion resistance.

- It’s often used in applications where high strength is required, such as heavy-duty structures, transportation, and automotive components.

4. Alloy 6005A:

- Alloy 6005A is known for its excellent extrudability and corrosion resistance.

- It’s used in applications requiring intricate extruded shapes, such as heat sinks, architectural components, and transportation structures.

5. Alloy 7005:

- Alloy 7005 is recognized for its high strength and fatigue resistance.

- It’s often used in lightweight structures, aerospace components, and high-stress applications.

6. Alloy 3003:

- Alloy 3003 is primarily used for extruded tubes and hollow sections due to its good formability.

- It’s commonly used for heat exchangers, air conditioning components, and other applications where corrosion resistance is essential.

7. Alloy 5005:

- Alloy 5005 is similar to 3003 in terms of formability and corrosion resistance.

- It’s used in applications like architectural trim, signage, and decorative components.

8. Alloy 1100:

- Alloy 1100 is commercially pure aluminum and has excellent formability.

- It’s often used for extruded products where corrosion resistance and appearance are important, such as lighting fixtures and decorative items.

These are just a few examples of aluminum alloy grades commonly used for extrusion. The choice of alloy grade depends on factors such as mechanical requirements, corrosion resistance, thermal properties, appearance, and cost considerations. It’s important to consult with materials experts or suppliers to select the appropriate alloy grade for your specific extrusion application.

Advantages of Aluminum Extrusion:

- Complex Shapes: Extrusion allows for the creation of complex shapes with consistent cross-sections, including intricate designs and hollow sections.

- Lightweight: Aluminum is lightweight, making extruded products suitable for applications where weight is a concern.

- Strength: Extruded aluminum profiles can be engineered to provide excellent strength-to-weight ratios.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, providing inherent resistance to corrosion.

- High Conductivity: Aluminum is an excellent conductor of heat and electricity.

- Versatility: Extruded aluminum finds applications in a wide range of industries due to its versatility and ease of customization.

- Sustainability: Aluminum is highly recyclable, making extruded products environmentally friendly.

Common applications of aluminum extrusion include window and door frames, curtain walls, heat sinks, automotive components, structural framing systems, electronics enclosures, and more. The versatility and adaptability of the extrusion process make it a valuable technique for shaping aluminum into various useful forms.

Commodities

Brochures

View our 2023 brochure for an easy to read guide on all of the services offer.