Through Hole Assembly Services for Durable Electronic Components

Reliable, High-Strength PCB Assembly for Power & Industrial Electronics

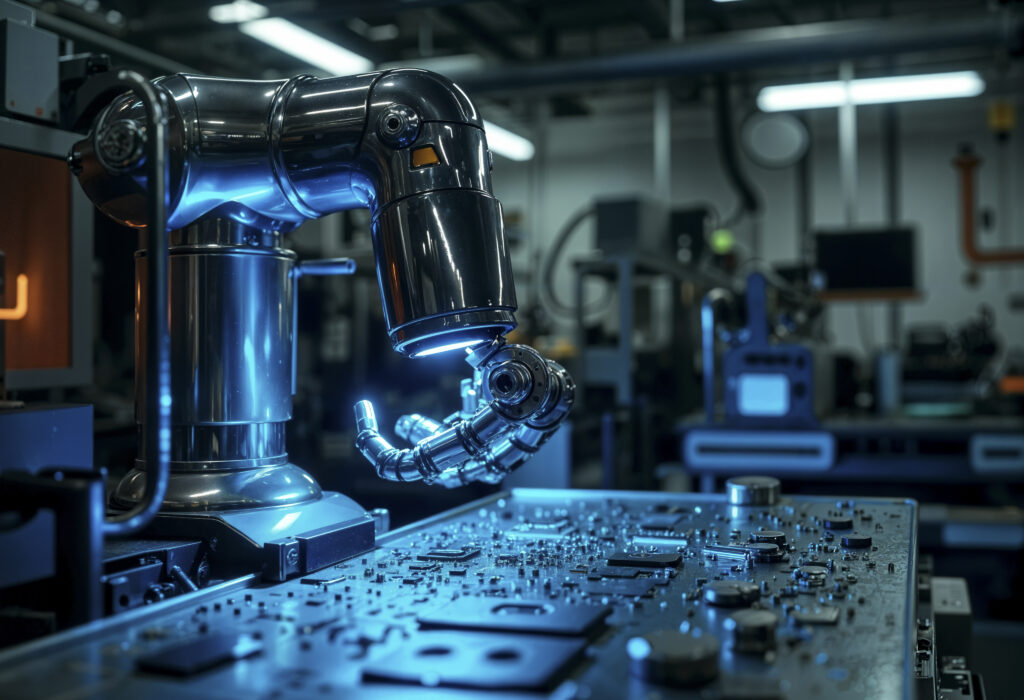

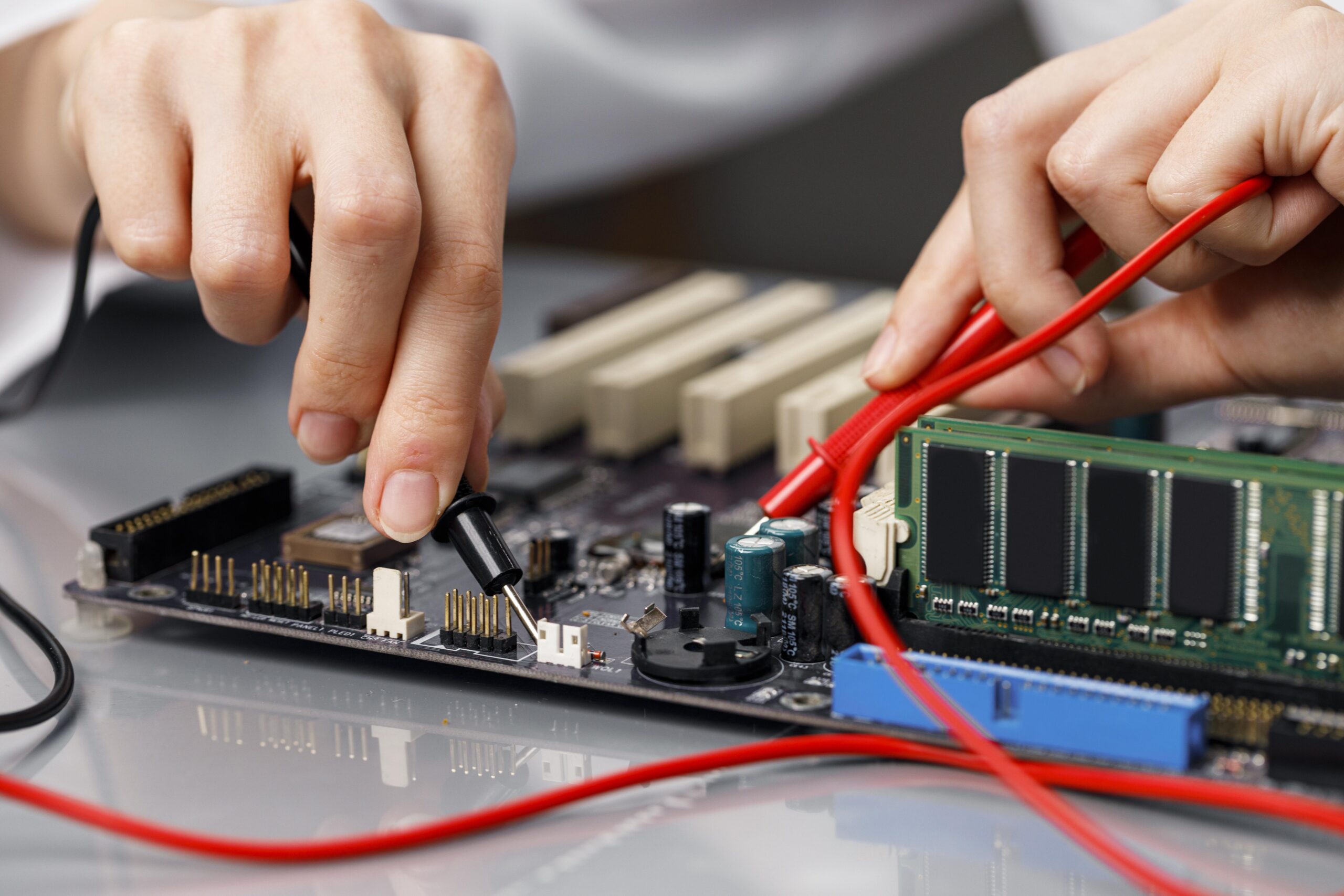

Manufyn offers precision through hole assembly services for customers seeking durability, mechanical strength, and performance under high-stress conditions. From automotive PCBs to power electronics and mission-critical industrial boards, our capabilities include both manual and automated through hole assembly tailored to your production needs.