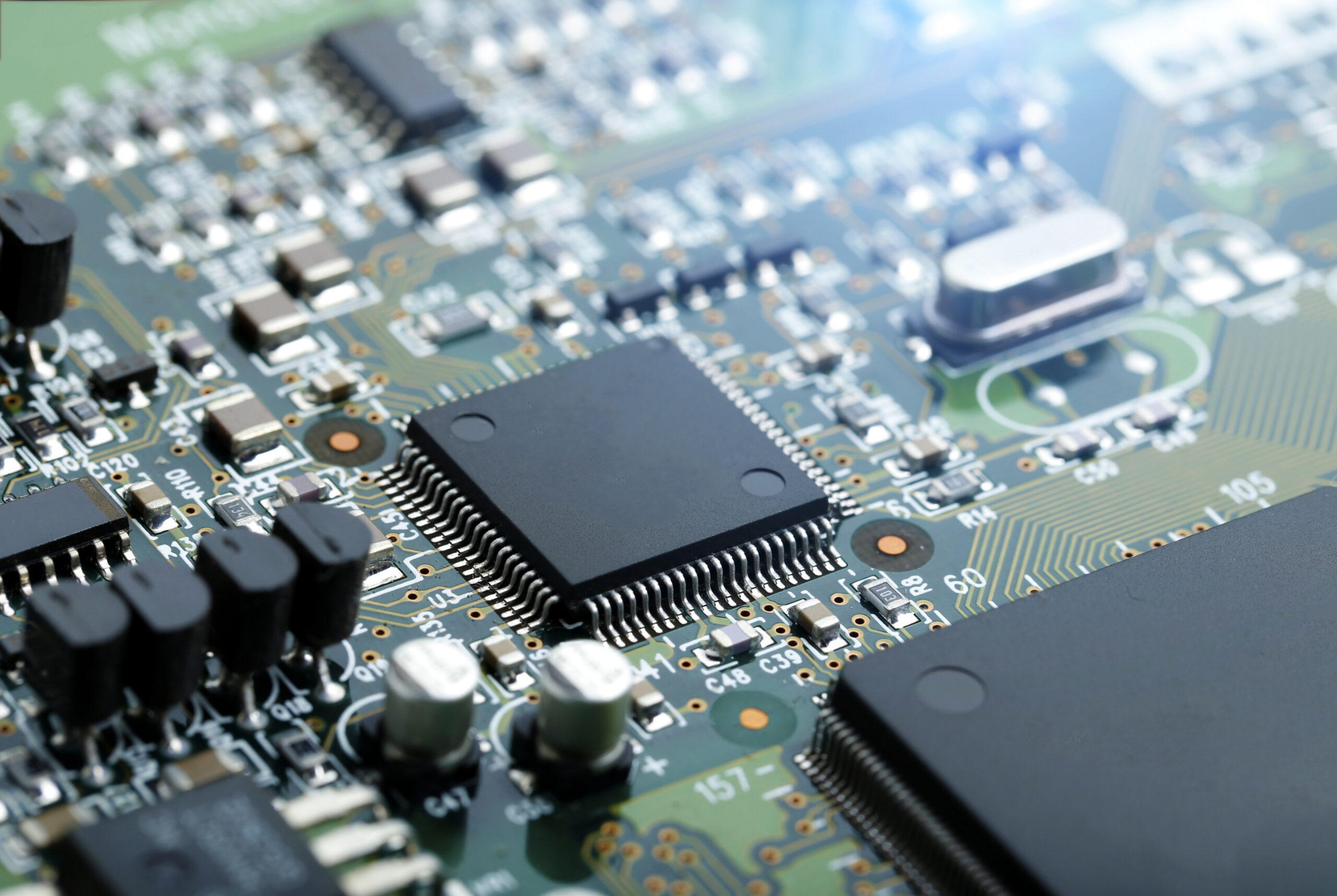

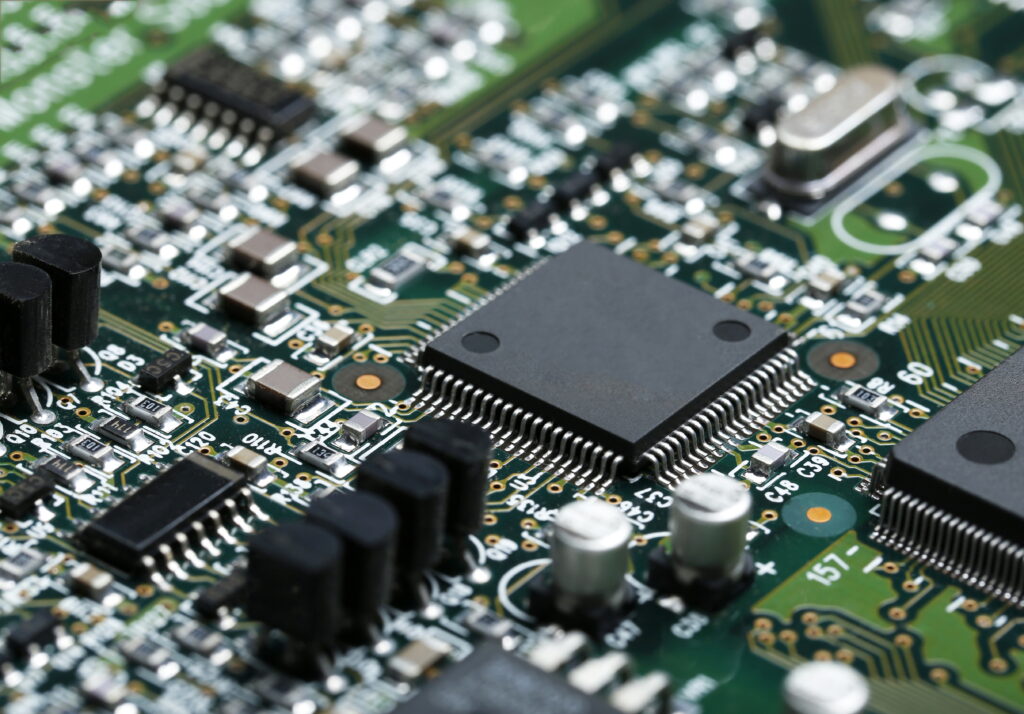

Surface Mount Technology Services for High-Speed PCB Assembly

Precision Electronics Assembly with Speed, Scale & Quality

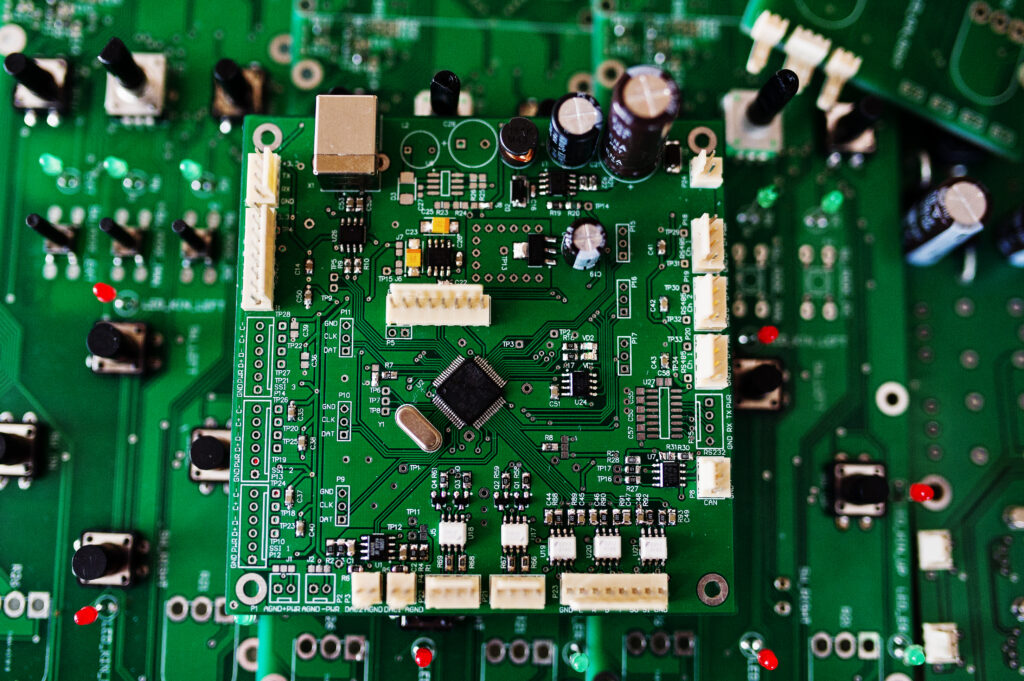

Manufyn offers end-to-end surface mount technology (SMT) services for assembling high-density, compact electronic components onto printed circuit boards (PCBs). Our SMT lines are powered by state-of-the-art surface mount technology machines that support both low-volume prototypes and high-volume production with exceptional accuracy and repeatability.