When it comes to modern manufacturing, injection moulding tooling is at the heart of creating precise, scalable, and cost-efficient plastic components. The tooling defines shape and accuracy and influences cycle time, unit cost, and product quality.

Whether you’re in automotive, medical, electronics, or consumer goods, success often depends on the reliability of your plastic injection mould tooling. Well-engineered tooling for injection moulding lets businesses move smoothly from prototype to mass production while keeping costs under control.

In this guide, we’ll cover types, materials, applications, challenges, and future trends of mould tooling. You’ll also see why partnering with Manufyn matters for your next project.

What is Injection mould Tooling?

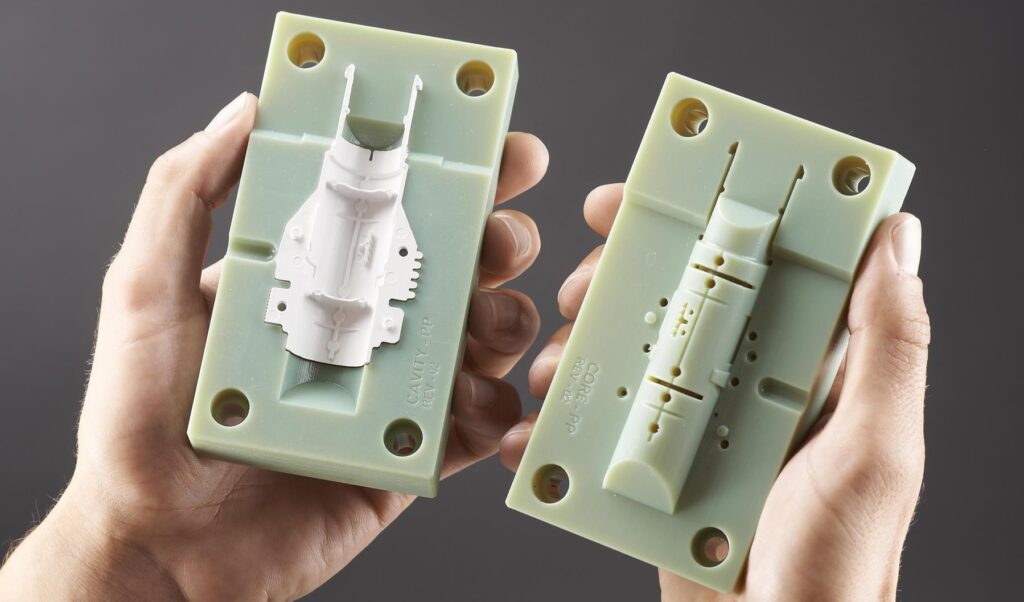

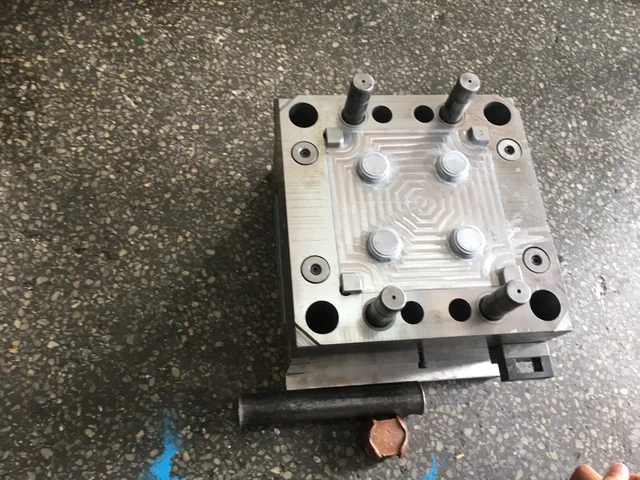

At its core, injection moulding tooling refers to the moulds or dies used to shape molten plastic into precise parts. These tools are designed using advanced CAD, CAM, and CAE technologies to capture every detail.

Without reliable plastic injection tooling, mass production of high-quality parts would be nearly impossible. High-quality injection mould tooling affects shape, cycle time, cost, surface quality, waste, consistency, and scalability.

Key Benefits of Injection moulding Tooling in Manufacturing

Injection moulding tooling plays a vital role in modern manufacturing by influencing accuracy, speed, cost, and quality. Below are the core benefits that make plastic injection mould tooling essential across industries.

Shape and Accuracy

Injection moulding tooling ensures products match design specifications. Small details are repeated consistently across thousands or millions of parts. That precision is essential in medical and automotive sectors relying on mould tooling.

Production Speed

mould tooling optimized for cycle time reduces cooling and ejection delays. Faster production increases throughput and lowers per-part time. Plastic injection tooling is one of the fastest scalable manufacturing methods.

Unit Cost

Durable plastic injection mould tooling lowers cost per unit over time. A single tool lasting millions of cycles amortizes the initial investment. That cost advantage suits high-volume production.

Surface Quality

High-quality injection moulding tooling produces smooth finishes that reduce post-processing. This saves labor and time for consumer electronics and packaging. Plastic tooling can deliver market-ready surfaces straight from the mould.

Waste Reduction

Precision tooling for injection moulding minimizes defects and scrap. Fewer rejects save material and cost. This also makes mould tooling a more sustainable manufacturing choice.

Scalability

With the right injection moulding tooling, businesses scale from prototypes to full production. The same tool can support pilot runs and mass manufacturing. This flexibility avoids frequent redesigns.

Ultimately, plastic injection mould tooling underpins efficiency, quality, and cost-effectiveness. Partnering with experienced providers like Manufyn gives access to engineering validation, supplier expertise, and long-lasting tools.

Types of Tooling for Injection moulding

There are many variations of injection moulding tooling designed for different products, materials, and volumes. Picking the right injection mould tooling ensures quality and efficiency.

mould Cavity

The mould cavity is the hollow space that shapes molten plastic into the final product. Precise cavity design ensures plastic injection mould tooling is accurate and repeatable. Multiple cavities increase output.

Example: Multi-cavity moulds are used in packaging for producing bottle caps.

Two-Plate moulds

Two-plate injection moulding tooling is common and cost-effective. It uses one parting line and is suitable for simple, high-volume products. This mould tooling is also easy to manufacture.

Example: Used in mass production of household items like containers and lids.

Three-Plate moulds

Three-plate moulds include two parting lines for complex geometries and easier runner separation. They allow gate placement at multiple points and improve ejection. Many manufacturers prefer this plastic tooling for cleaner parts.

Example: Applied in the production of medical casings and electronics housings.

Family mould

Family injection moulding tooling produces several related parts in one cycle. It reduces tooling costs and simplifies assembly by streamlining production for complementary components.

Example: Common in automotive manufacturing for producing dashboard components together.

Hot Runner mould

Hot runner injection mould tooling keeps plastic molten in runners, reducing material waste. Though more expensive upfront, it saves costs during high-volume production while boosting speed and efficiency.

Example: Widely used in consumer goods like packaging, where large volumes are required.

Stack mould

Stack injection moulding tooling uses multiple cavity levels to double output without requiring a larger press. It helps maximize productivity and lowers cost per part.

Example: Applied in large-scale production of food packaging containers.

Cube moulding

Cube moulding rotates cavities to inject different materials or colors in a single cycle. It is useful for creating complex designs while maintaining shorter cycles.

Example: Common in packaging, especially for multi-color or multi-material bottle caps.

Unscrewing moulds

Unscrewing injection moulds are designed for making threaded parts automatically, such as caps and closures. Built-in unscrewing mechanisms remove the need for secondary operations.

Example: Used in beverage and pharmaceutical bottle cap production

Inserts

Insert moulding integrates metal or pre-formed components into plastic during the moulding process. It creates strong hybrid parts while reducing assembly steps.

Example: Frequently used in electronics for embedding connectors into housings.

Overmoulding

Overmoulding bonds a softer material over a rigid substrate, often to improve grip or comfort. Specialized plastic injection tooling ensures consistency and strong adhesion.

Example: Common in tools and medical devices, such as syringes with soft grips.

Micro moulding

Micro injection moulding tooling creates extremely small and precise parts for industries requiring fine details. These moulds demand high levels of accuracy and advanced technology.

Example: Used in hearing aids, micro sensors, and surgical tools.

Gas Assist Injection moulding

Gas assist injection moulding uses pressurized gas to hollow out thick sections of plastic. This reduces weight, material use, and risk of warping.

Example: Common in automotive parts like handles and appliance housings.

Reaction Injection moulding (RIM)

Reaction injection moulding mixes liquid materials that chemically react inside the mould to form lightweight and durable parts. Specialized tooling is required.

Example: Frequently used for automotive bumpers and enclosures.

Rotational moulding

Rotational moulding rotates the mould during processing to evenly distribute material for hollow items. It is suitable for creating large, seamless products.

Example: Applied in manufacturing tanks, bins, and playground equipment.

Silicone Injection moulding

Silicone injection moulding tooling processes liquid silicone rubber into flexible and heat-resistant components. It is valuable in industries requiring durability and safety.

Example: Used in medical implants, gaskets, and electronic seals.

Injection moulding DFM

Design for Manufacturability (DFM) ensures parts can be efficiently produced. It considers draft angles, wall thickness, and runner placement to avoid costly design revisions.

Example: Applied in product design for consumer electronics before mass production.

Materials Often Used with Injection moulding Tooling

Material choice for injection moulding tooling affects durability, cost, and speed. Correct pairing of tool material and part plastic optimizes performance.

Hardened Steel

Hardened steel injection mould tooling is ideal for long runs and extreme wear resistance. It can last millions of cycles and suits high-volume precision parts.

Pre-Hardened Steel

Pre-hardened steel is more affordable than fully hardened steel and fits medium-volume runs. It balances cost with good durability for many plastic injection tooling projects.

Stainless Steel

Pre-hardened steel is more affordable than fully hardened steel and fits medium-volume runs. It balances cost with good durability for many plastic injection tooling projects.

Aluminum

Aluminum tooling is lightweight and quick to machine, making it great for prototypes and short runs. It wears faster than steel but lowers turnaround and cost.

Beryllium-Copper Alloys

Beryllium-copper alloys offer excellent thermal conductivity to speed cooling and cycle times. They’re useful for thin-walled parts in plastic injection tooling.

Hybrid Tooling

Hybrid tooling combines aluminum bodies with steel inserts to blend speed and durability. It’s popular for projects needing both rapid prototyping and wear resistance.

Nickel Coatings

Nickel coatings improve wear resistance and surface finish on mould tooling, extending life without replacing the base material.

P20 Tool Steel

P20 is a common, versatile tool steel with good machinability and toughness for general-purpose moulds.

Engineering Plastics for Tooling Applications

Some engineered plastics are also used around tooling or in components:

- Polycarbonate (PC): impact-resistant and clear.

- Polypropylene (PP): light and cost-effective.

- Poly(methyl methacrylate) (PMMA): acrylic for clarity.

- Acrylonitrile Butadiene Styrene (ABS): durable for electronics.

- Nylon (PA): tough and wear-resistant for gears.

Matching the right tool material with the moulded plastic ensures performance, longevity, and cost efficiency.

Applications of Plastic Injection mould Tooling

Injection moulding tooling is versatile and used across many sectors. The right tooling for injection moulding ensures parts meet strict quality and durability needs.

Automotive

The automotive sector relies on injection mould tooling to manufacture dashboards, trims, bumpers, and engine covers. Using durable materials like ABS and polypropylene ensures strong, lightweight components that improve fuel efficiency and maintain safety performance.

Consumer Goods

From toys and containers to kitchenware and appliance housings, plastic injection tooling enables high-volume, consistent production. The process guarantees smooth finishes, reliable dimensions, and affordable manufacturing for everyday consumer products used worldwide.

Medical Devices

Medical manufacturing demands precision and biocompatibility. Injection mould tooling is used for syringes, diagnostic kits, surgical tools, and casings for medical equipment. With materials like polycarbonate and silicone, tooling ensures sterile, safe, and reliable healthcare products.

Electronics

Electronics require durability and insulation. Plastic injection mould tooling produces mobile casings, circuit housings, and connectors with flame-retardant properties. Materials like ABS and polycarbonate provide lightweight, aesthetic, and functional designs critical for modern devices.

Heavy-duty industries depend on mould tooling for gears, housings, casings, and custom fittings. These components must endure stress, temperature, and wear. Injection moulding tooling ensures durability and repeatability for equipment that operates in demanding environments.

Aerospace

In Aerospace, reducing weight without sacrificing strength is vital. Plastic injection tooling creates lightweight, precise interior fittings, cable connectors, and ventilation parts. Using advanced polymers, manufacturers achieve reliable, safe, and fuel-efficient aerospace solutions.

Renewable Energy

The Renewable Energy sector increasingly depends on plastic injection mould tooling for solar housings, turbine connectors, and hydrogen enclosures. These parts must withstand environmental stress, UV exposure, and corrosion while remaining scalable and cost-efficient for energy projects.

Construction

Construction applications of mould tooling include fittings, panels, and insulation parts. With durable plastics like polypropylene and ABS, injection moulding delivers robust, weather-resistant, and affordable components tailored for long-lasting infrastructure solutions.

Across these applications, the adaptability of injection mould tooling helps companies lower costs and speed production.

Challenges in Injection Tooling & How to Overcome Them

Even with advantages, tooling for injection moulding faces common challenges. Understanding and mitigating these helps projects succeed.

High Upfront Costs

The initial investment for plastic injection mould tooling is often high due to advanced design, machining, and validation needs. Businesses can lower financial risks by starting with prototype tooling and phased investments before committing to full-scale production moulds.

Complex Designs

Undercuts, thin walls, and multi-material features complicate injection mould tooling and raise error risks. By applying DFM principles and simulation tools early, manufacturers identify potential issues and prevent costly redesigns or rework later in the production cycle.

Material Selection Issues

Choosing unsuitable materials for tooling or moulded parts can cause performance failures. Expert supplier guidance ensures that the correct plastic tooling materials are matched to the intended application, environment, and production volume for consistent results

Quality Consistency

Maintaining uniform output in high-volume runs is critical, especially in medical and automotive. Partnering with ISO-certified suppliers and using real-time quality monitoring ensures injection mould tooling consistently delivers accurate, defect-free parts.

Lead Times

Producing complex mould tooling often requires weeks or months, delaying project launches. Efficient project management, combined with a mix of local and global supplier networks, helps shorten timelines and ensures faster delivery of reliable tooling solutions.

Maintenance and Durability

Even the best plastic injection mould tooling wears down over time from pressure and temperature cycles. Implementing preventive maintenance schedules and regular inspections extends tool life, avoids production downtime, and maintains consistent part quality.

Defect Control

Warping, sink marks, short shots, and incomplete filling often stem from setup or tooling errors. Using simulation, gas assist technology, and predictive QC checks helps manufacturers prevent defects early and ensures smooth injection tooling operations.

Global Supply Chain Risks

Depending on a single supplier for injection mould tooling increases the risk of delays and disruptions. Diversifying vendors through vetted, global supplier networks, as Manufyn offers, reduces risks, ensures flexibility, and supports uninterrupted production

Working with an experienced partner like Manufyn minimizes these challenges. Their expertise in DFM, supplier vetting, and quality oversight ensures every plastic injection tooling project delivers efficiency, scalability, and long-term value.

Why Partner with Manufyn a Trusted Injection moulding Tooling Company?

Choosing the right partner for injection moulding tooling prevents delays, defects, and higher costs. Manufyn offers managed tooling for injection moulding, quality assurance, and global supplier networks.

End-to-End Services

Manufyn delivers complete injection mould tooling support, including CAD/CAM validation, prototyping, design, manufacturing, and logistics. By handling everything under one roof, businesses save time, avoid miscommunication, and streamline their plastic injection tooling projects.

Cost Efficiency

Through optimized sourcing and supplier selection, Manufyn reduces the total cost of ownership for plastic tooling. Working only with ISO-certified suppliers ensures competitive pricing while maintaining durability, quality, and compliance with international standards.

Time Savings

A managed global supplier network allows Manufyn to shorten lead times for mould tooling projects. From prototypes to large-scale production, businesses benefit from faster execution and on-time delivery, reducing delays and improving time-to-market efficiency.

Scalability

Manufyn’s services are designed to scale with your needs—from small prototype tools to high-volume injection mould tooling for mass production. This flexibility supports startups, SMEs, and multinational companies without compromising precision or quality.

Quality Assurance

Strict inspection processes, ISO certifications, and global quality standards guarantee reliable performance in every plastic injection tooling project. Manufyn ensures consistent product quality through defect control, testing, and supplier audits at all stages.

Risk Mitigation

By diversifying suppliers and maintaining strong project oversight, Manufyn minimizes risks such as delays, defective parts, or supply disruptions. This structured approach ensures your injection mould tooling projects stay on track and within budget

Single-Window Solutions

Manufyn acts as a single accountable partner for mould tooling needs, simplifying procurement, logistics, and communication. With one trusted contact managing your project, execution becomes smoother and less complicated for businesses of all sizes.

Added Expertise

Beyond tooling and injection moulding, Manufyn also supports contract manufacturing and renewable energy initiatives like Solar EPC and green hydrogen. This versatility allows clients to benefit from future-ready, innovative solutions across industries.

The Manufyn advantage is cost efficiency, scalability, and reliable project execution.

Future Trends in Injection Tooling

The world of injection moulding tooling is evolving rapidly. New technologies and sustainability goals are transforming how plastic injection mould tooling is designed, built, and maintained, making production faster, smarter, and greener.

3D Printing of Tooling Components

Additive manufacturing is speeding up the creation of inserts and prototypes for injection mould tooling. By using 3D printing, companies reduce machining costs, test designs faster, and validate geometry before committing to full-scale tooling

Conformal Cooling Channels

Cooling efficiency drives cycle time reduction in plastic injection mould tooling. Conformal cooling channels follow the shape of cavities, ensuring uniform heat removal, shorter cycles, fewer defects, and higher-quality moulded components

Smart moulds with IoT Sensors

IoT-enabled mould tooling integrates sensors to monitor temperature, pressure, and cycle data in real time. This smart feedback enables predictive maintenance, reduces unplanned downtime, and extends the lifespan of injection mould tooling.

AI-Driven mould Design

Artificial Intelligence is being applied to injection moulding tooling to optimize gate placement, flow balance, and cooling layouts. AI-driven analysis improves efficiency, reduces trial errors, and shortens development cycles for complex moulds.

Eco-Friendly Tooling Materials

Sustainability in plastic injection tooling is driving the use of recyclable metals, hybrid alloys, and coatings that extend tool life. These eco-friendly solutions reduce waste, cut costs, and align with green manufacturing goals globally.

Automated Maintenance Alerts

Predictive maintenance systems embedded in injection mould tooling detect wear before failure occurs. Automated alerts allow timely servicing, reducing unexpected breakdowns and keeping production lines running smoothly with minimal downtime.

Global Collaboration Platforms

Cloud-based project management platforms allow teams worldwide to collaborate on tooling for injection moulding in real time. This digital approach accelerates design approvals, reduces errors, and enables agile development cycles.

Green Manufacturing Integration

As industries adopt solar, wind, and hydrogen, plastic injection mould tooling is aligning with green practices. Lightweight, durable, and recyclable plastics support eco-friendly projects while ensuring efficiency and cost savings.

Manufyn helps clients adopt these trends to stay competitive and sustainable.

Conclusion

At its core, injection moulding tooling is the backbone of modern plastic manufacturing. It determines accuracy, efficiency, and cost-effectiveness across industries.

Businesses that invest in durable, well-designed plastic injection mould tooling gain long-term savings, higher quality, and scalability. Choosing the right partner is equally critical; Manufyn offers validation, global supplier management, and quality assurance.

By embracing AI-driven design, 3D printing, and sustainable materials, manufacturers can future-proof their tooling programs. With Manufyn as a partner, every plastic tooling project starts strong and finishes stronger.

Looking for reliable, cost-effective, and future-ready injection moulding tooling solutions? Partner with Manufyn today to gain precision, speed, and global competitiveness.

FAQs on Injection moulding Tooling

Injection mould tooling refers to the precision moulds used in the injection moulding process. It plays a vital role in determining part accuracy, surface finish, cycle time, and overall efficiency of the final plastic product.

Common types include prototype tooling, production tooling, family moulds, and multi-cavity moulds. Each serves specific purposes, from testing early designs to producing millions of identical parts in continuous high-volume runs.

Steel and aluminum are the most widely used materials for injection mould tooling. Steel offers exceptional durability for high-volume runs, while aluminum is cost-effective and ideal for prototyping or low-volume production batches.

Industries such as automotive, consumer electronics, packaging, medical devices, and industrial equipment depend heavily on injection mould tooling to produce high-quality, durable, and scalable plastic components at competitive costs.

Prototype tooling is designed for small runs and testing product designs before scaling. In contrast, production tooling is built with higher durability, allowing continuous, high-volume manufacturing with consistent accuracy and efficiency.

Costs for injection mould tooling vary depending on complexity, design, material, and mould size. Partnering with companies like Manufyn helps optimize costs by leveraging vetted supplier networks and expert project management services.

Yes, plastic injection tooling is highly customizable. With CAD, CAM, and CAE support, moulds can be engineered to meet specific product requirements, enabling unique designs while ensuring durability, efficiency, and manufacturing precision.

Injection moulding tooling often faces challenges such as high upfront costs, design complexities, and ensuring quality consistency. These issues are minimized with expert suppliers, design validation, and strict quality oversight systems.

Manufyn provides end-to-end services covering design validation, prototyping, tooling, production, and quality checks. Its global supplier network ensures cost efficiency, scalability, and international quality standards for reliable solutions.

The lifespan of plastic injection mould tooling depends on material, design, and usage. Steel moulds can endure millions of cycles with proper maintenance, while aluminum tooling is better suited for short runs or prototype applications.

Read More

Start Your Project Today

Ready to optimize your solar EPC project cost? Partner with Manufyn India Private Limited for turnkey execution, global sourcing, and renewable energy innovation.