Plastic parts play a vital role in almost every industry, from automobiles and electronics to healthcare and consumer goods. Among the many manufacturing methods, injection moulding plastic parts has become the most popular because of its scalability, precision, and cost-effectiveness.

By using advanced tooling and specialized machinery, manufacturers can create high-quality plastic injection parts that meet strict dimensional and durability requirements. This process not only supports mass production but also enables customization for complex shapes.

In this guide, we’ll explore the parts of injection moulding, explain how to create plastic parts, and discuss the wide-ranging applications of injection moulding parts in modern industries.

What Are Plastic Injection Parts?

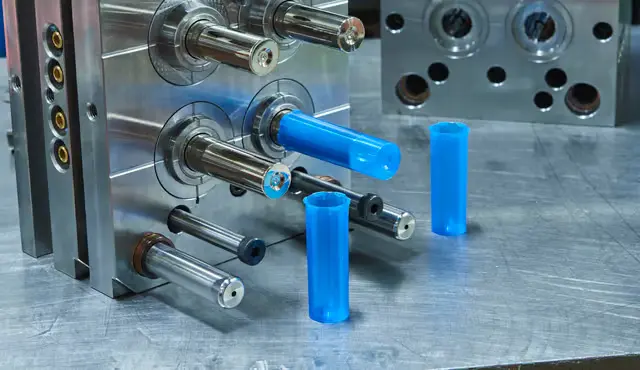

Plastic injection parts are components made using the injection moulding process, where molten plastic is injected into a mold to form a specific shape. These parts are widely used because they deliver consistency, high strength, and design flexibility.

The terms plastic moulding parts and injection plastic parts are often used interchangeably, but they highlight the same concept: manufacturing durable and lightweight components through moulding techniques. Whether it’s plastic injection parts for consumer products or injection moulding automobile parts for the automotive sector, this method ensures reliable performance at scale.

By choosing injection moulding services, companies gain access to fast production cycles, cost savings, and the ability to manufacture parts in bulk with minimal waste.

Parts of the Injection Moulding Process

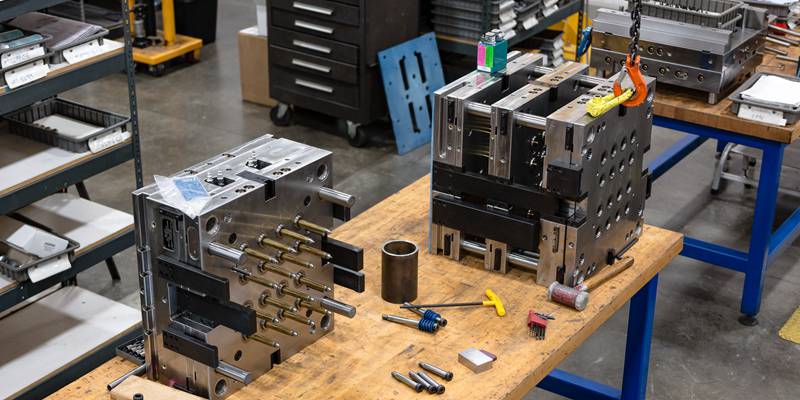

To understand injection moulding plastic parts, it’s essential to know the main parts of injection moulding machines and how they work together. Each element plays a critical role in producing high-quality plastic moulding parts.

Key Parts of Injection Moulding Machines:

Hopper – This is where plastic granules are loaded before melting. The type of plastic used directly influences the strength and durability of plastic injection parts.

Heated Barrel – The granules are melted here under controlled temperature. A consistent melt ensures defect-free injection moulding parts.

Injection Unit – This pushes the molten plastic into the mold cavity. The efficiency of this unit impacts cycle time and final part quality.

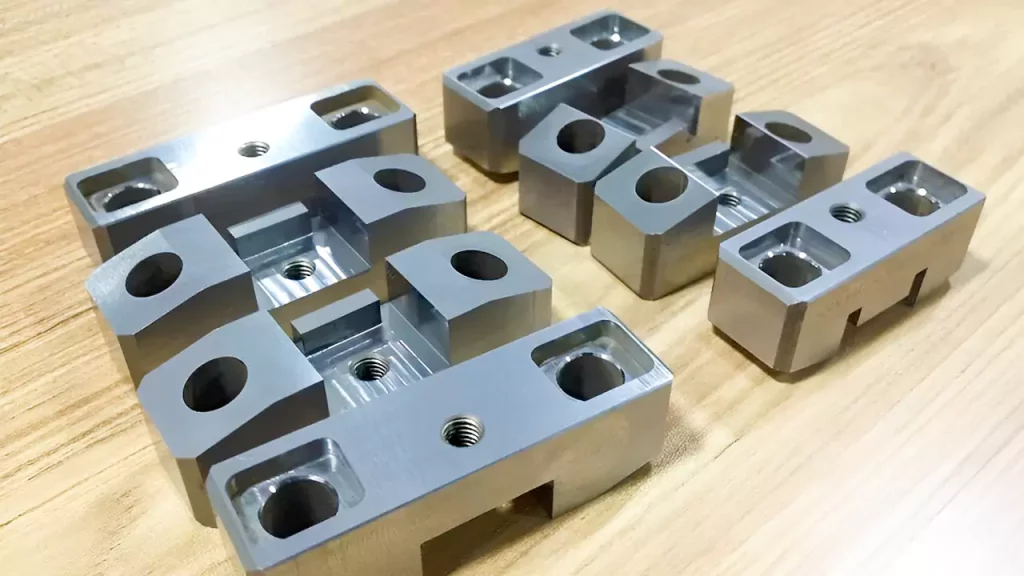

Mold (Tooling) – The mold is the most critical element, defining the shape of injection plastic parts. Advanced tooling allows production of complex geometries for sectors like injection moulding automobile parts.

Clamping Unit – It holds the mold in place during injection and ensures proper pressure. Weak clamping can result in incomplete plastic moulding parts.

Cooling System – Once the part is formed, cooling solidifies the material into the final shape. Faster cooling means shorter production cycles, but it must be carefully balanced to avoid defects.

By understanding these parts of injection moulding, manufacturers and designers can optimize production and minimize defects in plastic moulding parts.

How to Create Plastic Parts: Step-by-Step Process

Designers, engineers, and manufacturers often ask how to create plastic parts using injection moulding. The process is systematic and ensures scalable, repeatable production of plastic injection parts for industries such as automotive, electronics, and consumer goods.

Step 1: Product Design

Every project begins with a digital 3D model. The design stage defines the geometry, thickness, and tolerances of injection plastic parts, ensuring they meet functional and aesthetic requirements.

Step 2: Mold Design & Tooling

Once the part is designed, the mold is created. Since the moulding form dictates the final outcome, precision tooling is crucial for high-quality injection moulding parts.

Step 3: Material Selection

Choosing the right thermoplastic is key. Different plastics offer varied strength, flexibility, and heat resistance, impacting the performance of plastic moulding parts.

Step 4: Injection Moulding Procedure

The molten plastic is injected into the mold cavity under high pressure. This step converts raw material into functional plastic injection parts with exact dimensions.

Step 5: Cooling and Ejection

After injection, the material cools inside the mold and solidifies. The finished injection moulding plastic parts are then ejected, ready for finishing.

Step 6: Post-Processing & Quality Check

Some injection moulding automobile parts or electronic enclosures require trimming, surface finishing, or coating. Each injection moulding part undergoes strict quality checks before delivery.

This step-by-step workflow ensures that every batch of plastic moulding parts is consistent, durable, and suitable for its intended application.

Applications of Plastic Injection Parts Across Industries

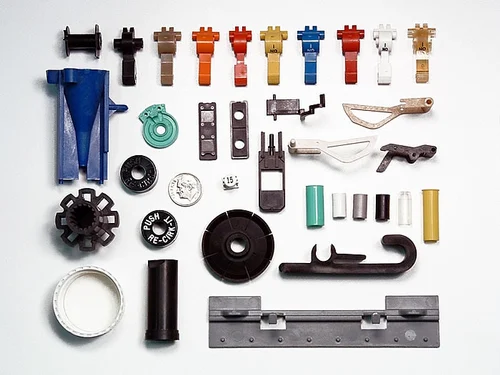

The versatility of plastic parts makes injection moulding one of the most widely used manufacturing processes worldwide. From everyday products to highly engineered systems, injection moulding plastic parts are used across industries to improve efficiency, reduce costs, and ensure scalability.

1. Automotive Industry

Modern vehicles rely heavily on injection moulding automobile parts. Components such as dashboards, bumpers, interior panels, and precision clips are created using plastic injection parts for durability, lightweight performance, and safety compliance.

2. Electronics & Appliances

Consumer electronics and home appliances require intricate injection plastic parts such as switch housings, connectors, and enclosures. These plastic moulding parts are engineered for strength, insulation, and heat resistance.

3. Medical Devices

The medical sector uses precision injection moulding parts in syringes, diagnostic devices, and casings for advanced equipment. These plastic parts are manufactured with high accuracy and compliance with global safety standards.

4. Industrial & Heavy Equipment

Large-scale machinery depends on durable plastic moulding parts that withstand pressure, chemicals, and extreme operating conditions. Examples include gears, seals, and housings produced using advanced injection moulding plastic parts technology.

5. Consumer Goods

Everyday products like toys, storage containers, kitchen tools, and packaging rely on plastic injection parts. This wide demand showcases the role of parts of injection moulding in high-volume, cost-effective production.

6. Transportation & Railways

Injection moulding parts also play a role in railway and public transport systems. Lightweight plastic moulding parts improve efficiency, reduce maintenance, and extend product lifespan.

By exploring these applications of plastic injection parts, it’s clear why injection moulding plastic parts are central to industries ranging from automotive to healthcare and beyond.

Why Choose Manufyn for Injection Moulding Plastic Parts

When it comes to sourcing plastic injection parts or scaling production of injection moulding plastic parts, businesses need a trusted partner who ensures quality, speed, and cost efficiency. Manufyn specializes in delivering plastic moulding parts for global industries with complete end-to-end support.

What Sets Manufyn Apart?

- Expertise in Multiple Applications

From injection moulding automobile parts to precision healthcare components, we manufacture injection moulding parts across diverse industries. - Custom Design & Engineering

Our team provides design for manufacturability (DFM) support, helping companies understand the parts of injection moulding and optimize them for production. - Prototyping & Pilot Runs

Unsure how to create plastic parts efficiently? We assist with injection moulding prototypes so you can test functionality before mass production. - Certified Indian Manufacturers

We connect you with verified injection plastic parts manufacturers in India, ensuring compliance, scalability, and competitive pricing. - Global Supply Chain Management

Whether you are sourcing injection moulding plastic parts from India to the USA, Australia, or Europe, Manufyn manages logistics, QC, and timely delivery. - Cost-Effective Solutions

With transparent pricing, accurate injection moulding quotes, and predictable timelines, we make scaling with plastic injection parts risk-free.

At Manufyn, we don’t just manufacture; we act as your complete outsourcing partner for injection moulding parts, from prototypes to full-scale production.

Conclusion: Reliable Plastic Injection Parts with Manufyn

The demand for high-quality plastic parts continues to rise across industries like automotive, electronics, healthcare, and infrastructure. By understanding the parts of injection moulding and working with experienced partners, businesses can achieve defect-free, scalable production.

Whether you need injection moulding plastic parts, plastic moulding parts for everyday products, or specialized injection moulding automobile parts, the key is choosing a partner who ensures precision, compliance, and cost-effectiveness.

At Manufyn, we simplify sourcing and production of injection plastic parts by connecting you with India’s top-certified manufacturers. From design assistance and prototyping to mass production and export logistics, we provide complete solutions that make scaling easier and smarter.

Ready to bring your designs to life with the right partner?

Request a Free Consultation today and discover how Manufyn can help you manufacture world-class plastic injection parts with reliability and speed.

Frequently Asked Questions on Plastic Injection Parts

Plastic injection parts are components manufactured using injection moulding, a process where molten plastic is injected into a mould. These plastic injection parts are widely used in electronics, automotive, and consumer industries.

The parts of injection moulding include the injection unit, clamping system, mould cavity, and cooling channels. Together, they ensure accurate production of injection moulding plastic parts with repeatable quality.

If you’re asking how to create plastic parts, the process involves designing a mould, selecting material, and injecting molten plastic under pressure. This allows cost-efficient, scalable production for both prototypes and mass runs.

Injection moulding plastic parts are used in a variety of products, from medical devices and home appliances to injection moulding automobile parts like dashboards, bumpers, and connectors.

While often used interchangeably, plastic moulding parts generally refer to any plastic formed by moulding methods. Injection plastic parts specifically come from the injection moulding process, offering tighter tolerances and scalability.

Injection moulding automobile parts provide durability, precision, and cost-efficiency for OEMs. They include critical components such as housings, brackets, and interior fittings manufactured at scale with high accuracy.

Using injection moulding parts lowers costs by reducing waste, shortening cycle times, and allowing bulk production. This efficiency makes plastic moulding parts ideal for industries requiring large volumes.

Reliable suppliers perform inspections on plastic injection parts, including dimensional checks, stress tests, and visual inspections. At Manufyn, every batch undergoes third-party QC to ensure defect-free delivery.

Yes. Many companies create prototypes of injection plastic parts to test design and functionality before moving into full-scale production. This reduces risks and prevents costly redesigns.

Manufyn simplifies global sourcing of plastic parts by connecting businesses with verified Indian manufacturers. From plastic injection parts to large-scale injection moulding parts, we ensure compliance, scalability, and cost-effectiveness.

Read More

Start Your Project Today

Manufyn makes on-demand manufacturing easy. Get your quote and begin your project now