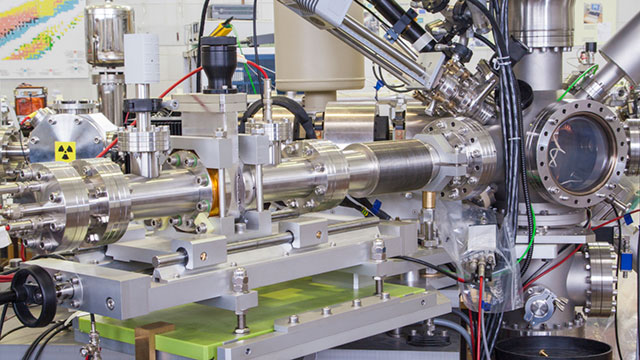

In today’s innovation-driven world, mass spectrometers have become indispensable across industries like pharmaceuticals, biotechnology, environmental science, food safety, and more.

These complex instruments provide unmatched precision in identifying, measuring, and analyzing compounds but their increasing demand also places enormous pressure on mass spectrometer manufacturers to deliver high-quality, scalable production.

However, manufacturing a mass spectrometer isn’t straightforward. It involves ultra-tight tolerances, advanced engineering, specialized materials, and robust quality controls. As the demand for high-performance spectrometers grows, so does the need for manufacturing partners who can keep pace without compromising on precision.

That’s where Manufyn comes in.

As a trusted partner for mass spectrometer manufacturers, we specialize in prototyping, small-batch production, and seamless scaling into mass manufacturing.

With cutting-edge technology, strict quality standards, and a focus on innovation, Manufyn helps you bring your most advanced designs to life, faster, smarter, and at scale.

The Growing Importance of Mass Spectrometer Manufacturers

From ensuring the purity of life-saving drugs to detecting trace contaminants in drinking water, mass spectrometers are at the heart of modern research and industry innovation. Their applications span a wide range of sectors, making mass spectrometer manufacturers a critical part of global technological progress.

Here are some of the most significant areas driving demand for mass spec manufacturers:

Pharmaceutical & Biotechnology Research

Supporting drug discovery, quality control, and molecular analysis.

Environmental Monitoring

Detecting pollutants, toxins, and greenhouse gases with unmatched precision.

Food & Beverage Safety

Ensuring regulatory compliance by identifying contaminants and verifying product quality.

Forensics & Material Science

Helping experts solve complex cases and develop advanced materials.

As industries evolve, the role of mass spectrometer manufacturers goes beyond just producing instruments; they must now enable faster innovation, flexible production capabilities, and scalable manufacturing to meet growing global needs.

This is where Manufyn stands out.

By partnering with us, manufacturers gain access to advanced engineering, rapid prototyping, and mass production expertise empowering you to stay ahead in a highly competitive market.

Challenges Faced by Mass Spec Manufacturers

Manufacturing mass spectrometers is unlike building any other laboratory instrument. These devices require extreme precision, advanced engineering, and compliance with rigorous global quality standards.

For many mass spectrometer manufacturers, staying competitive while maintaining accuracy, reliability, and scalability can be a real challenge.

Here are some of the most common pain points in the industry:

Achieving Ultra-High Precision

Mass spectrometers rely on components engineered to micron-level tolerances. A tiny deviation in machining or assembly can compromise the accuracy of the entire device. For mass spec manufacturers, achieving this level of precision consistently requires advanced manufacturing capabilities and highly skilled expertise.

Sourcing Specialized Materials

Not every manufacturer has access to the rare alloys, coatings, and components needed to produce spectrometers that meet performance benchmarks. Shortages, high costs, and quality inconsistencies make material sourcing a significant hurdle.

Limited Prototyping Capabilities

Innovations in spectrometer design require rapid prototyping to test and refine new concepts. However, many manufacturers lack the infrastructure for small-batch production, slowing down innovation and time-to-market.

Scaling from Prototype to Mass Production

Transitioning from low-volume prototyping to large-scale manufacturing is one of the toughest challenges in the industry. Without the right systems and supply chain management in place, maintaining precision while scaling output becomes risky and expensive.

Strict Compliance & Quality Standards

Mass spectrometer manufacturers must adhere to multiple global certifications, including ISO standards, calibration requirements, and performance testing benchmarks. Meeting these demands consistently calls for robust quality control measures at every production stage.

This is where Manufyn bridges the gap.

We help mass spec manufacturers overcome these hurdles through advanced engineering, rapid prototyping, and scalable manufacturing solutions — ensuring every spectrometer meets the highest standards of performance and reliability.

Why the Right Manufacturing Partner Changes Everything

When you’re producing high-performance instruments like mass spectrometers, choosing the right manufacturing partner isn’t optional it’s critical to success. The right partner doesn’t just build your product; they accelerate your innovation, reduce risks, and enable scalability.

Here’s what to look for when selecting a partner and how Manufyn delivers on every front:

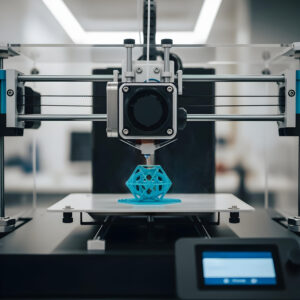

Expertise in Prototyping and Small-Batch Production

A strong manufacturing partner should help you test, refine, and validate designs quickly through rapid prototyping and small-batch runs. At Manufyn, we enable faster product iterations to reduce development cycles and get your innovations market-ready sooner.

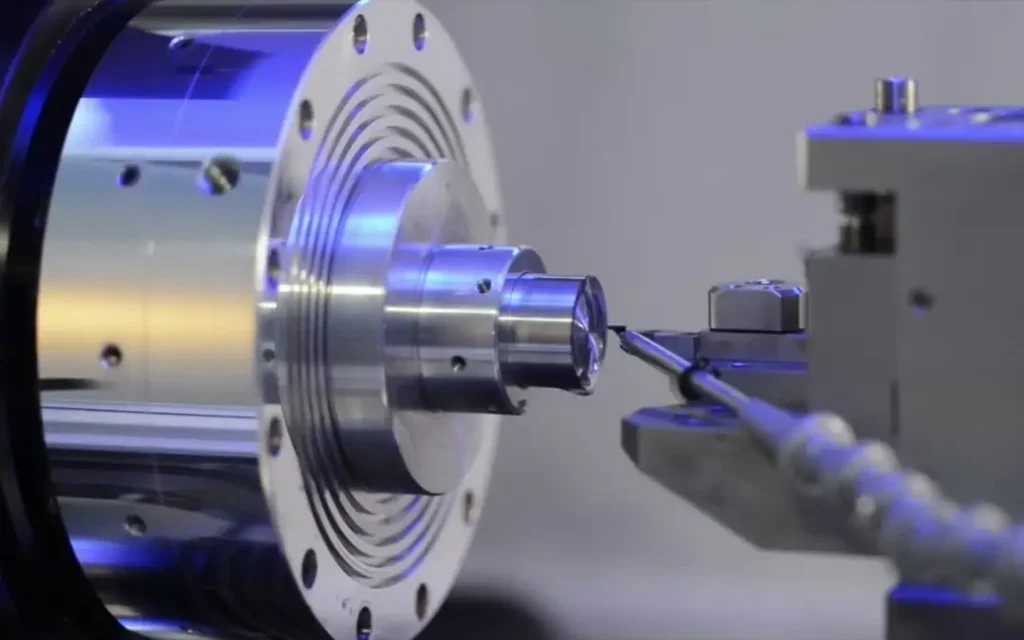

Precision Engineering Capabilities

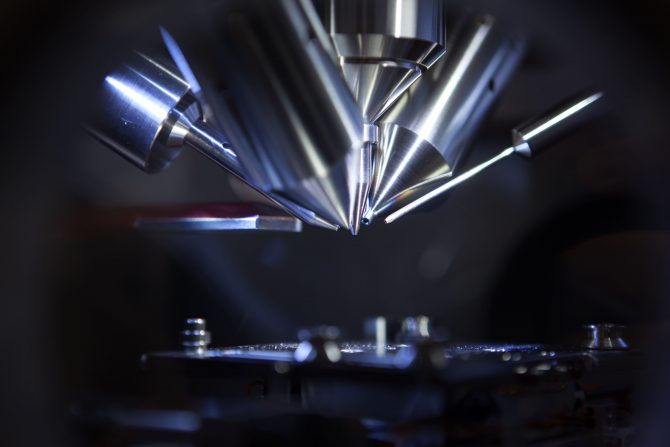

Spectrometers demand micron-level accuracy. Our advanced CNC machining, custom tooling, and multi-axis manufacturing capabilities ensure your components are built to exact tolerances — every single time.

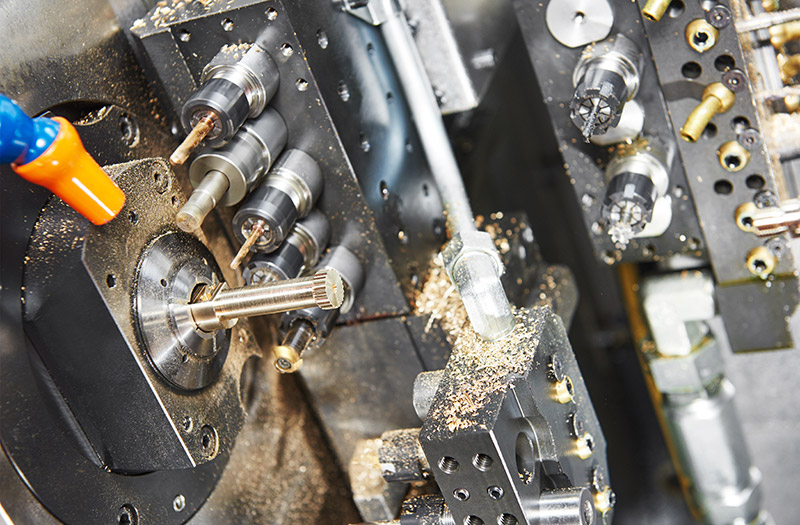

Seamless Transition to Mass Production

Scaling up without sacrificing quality is where many manufacturers struggle. Manufyn specializes in helping mass spectrometer manufacturers move smoothly from prototype to full-scale production, ensuring consistent performance across every unit.

Strict Quality Control & Certifications

We understand the importance of reliability in laboratory instruments. That’s why we implement ISO-certified processes, rigorous testing, and multiple checkpoints to guarantee compliance with industry standards.

Transparent Communication & End-to-End Support

From design consultation to material sourcing and delivery, we work closely with you at every stage making the entire manufacturing journey seamless and predictable.

With Manufyn as your manufacturing partner, you don’t just get a supplier you gain a strategic ally committed to helping you innovate faster, manufacture smarter, and scale seamlessly.

Manufyn: Your Trusted Partner for Mass Spectrometer Manufacturing:

When it comes to manufacturing highly sophisticated instruments like mass spectrometers, you need more than just a supplier, you need a strategic partner who understands the technical challenges, regulatory demands, and scaling requirements of your business. Manufyn is that partner.

Here’s how we empower mass spectrometer manufacturers to innovate faster and scale smarter:

Rapid Prototyping & Small-Batch Production

We support mass spec manufacturers in the early stages of product development with fast prototyping and low-volume runs. This enables you to test designs, iterate quickly, and reduce time-to-market — without overcommitting resources.

Precision Engineering at Scale

Mass spectrometers demand micron-level tolerances and flawless assemblies. At Manufyn, we leverage advanced CNC machining, custom tooling, and multi-axis capabilities to deliver components that meet exact specifications every time.

Seamless Transition to Mass Production

One of the biggest challenges for mass spectrometer manufacturers is scaling production while maintaining consistency. With Manufyn, this transition is effortless. We help you move from small-batch runs to high-volume manufacturing without compromising on accuracy, quality, or timelines.

Robust Quality Control & Certifications

Every spectrometer component we produce undergoes stringent testing and ISO-certified quality checks. We ensure that every unit aligns with global standards for reliability and performance.

End-to-End Manufacturing Support

From design validation and material sourcing to assembly and delivery, Manufyn offers complete manufacturing solutions. We act as an extension of your engineering team, providing transparency and collaboration at every step.

Whether you’re a growing startup or an established industry leader, Manufyn helps you prototype faster, manufacture smarter, and scale seamlessly — making us the go-to partner for mass spectrometer manufacturers worldwide.

Why Scalable Mass Production Matters for Mass Spec Manufacturers

In today’s competitive market, speed and scalability define success. For mass spectrometer manufacturers, the ability to move quickly from prototyping to mass production isn’t just an advantage — it’s a necessity.

Here’s why scalable manufacturing matters more than ever:

Faster Time-to-Market

With demand for mass spectrometers soaring across industries, delays can cost you opportunities. Manufyn ensures a smooth, efficient transition from design validation to full-scale production, helping you deliver products faster.

Consistent Quality at Every Stage

Scaling up often risks losing quality control, but with Manufyn’s ISO-certified processes and robust QA systems, every unit meets the same high-performance standards — whether we’re producing 10 units or 10,000.

Cost Efficiency Without Compromise

We optimize manufacturing workflows and supply chains to ensure cost-effective scaling while maintaining precision engineering and reliability.

Future-Ready Scalability

Innovation in mass spectrometer manufacturing is constant, and your production partner must keep up. At Manufyn, we offer flexible manufacturing solutions that evolve with your technology, ensuring you stay ahead of the curve.

By choosing Manufyn, mass spec manufacturers get more than just production support; they gain a scaling partner committed to precision, speed, and efficiency.

Conclusion: Scale Your Mass Spectrometer Manufacturing with Manufyn

As industries like pharmaceuticals, biotech, food safety, and environmental monitoring continue to innovate, the demand for high-performance mass spectrometers is only accelerating. For mass spectrometer manufacturers, this means one thing: the need to innovate faster, produce smarter, and scale seamlessly has never been greater.

That’s exactly where Manufyn comes in.

With our end-to-end manufacturing solutions, we help mass spec manufacturers overcome the toughest challenges — from rapid prototyping and small-batch production to high-volume, precision-driven manufacturing.

Our advanced engineering capabilities, ISO-certified quality controls, and reliable supply chain management make us the go-to partner for companies looking to bring complex spectrometers to market efficiently and at scale.

Whether you’re a startup developing cutting-edge devices or an established leader in the industry, Manufyn ensures your products are manufactured with unmatched precision and ready to scale when you are.

Ready to take your spectrometer manufacturing to the next level?

Explore Manufyn’s mass production capabilities ➜

FAQs About Mass Spectrometer Manufacturers

Mass spectrometer manufacturers design, engineer, and produce precision instruments used to analyze the composition of materials. They handle everything from component prototyping to full-scale mass production, ensuring accuracy, reliability, and compliance with global standards.

When selecting a mass spec manufacturer, consider:

- Precision engineering capabilities

- Prototyping and small-batch production support

- Scalability for mass production

- Quality certifications and testing protocols

Manufyn delivers all of these, making us the preferred choice for leading spectrometer companies.

Not necessarily. Some mass spectrometer manufacturers specialize only in prototyping or small-scale runs. Manufyn stands out by providing end-to-end manufacturing solutions, from rapid prototyping to high-volume production.

Mass spectrometers rely on micron-level tolerances to deliver accurate readings. Even the slightest deviation can affect performance. At Manufyn, we use advanced CNC machining and custom tooling to ensure every component meets exact specifications.

Manufyn bridges the gap between prototype development and mass production by offering:

- Rapid small-batch runs

- Seamless scaling to high-volume manufacturing

- ISO-certified quality controls

- Efficient supply chain management

This makes us the ideal partner for companies looking to grow fast without compromising quality.

Mass spectrometers are widely used in:

- Pharmaceuticals and biotechnology

- Environmental monitoring

- Food and beverage safety

- Forensic science and material research

With Manufyn’s manufacturing expertise, these industries get the precision and scalability they need.

Absolutely. Manufyn specializes in prototyping, small-batch manufacturing, and mass production. We ensure a seamless transition between development and scaling, saving you time, cost, and operational headaches.

Because Manufyn offers precision engineering, scalable production, rigorous quality assurance, and transparent project management. We don’t just manufacture components; we enable innovation and accelerate your growth.