Injection molding is one of the most cost-effective manufacturing methods used across industries to produce high-quality plastic components at scale. However, understanding injection moulding costs can be confusing, especially when you’re comparing tooling expenses with per-part pricing.

In India, where manufacturing demand is booming, businesses often struggle to balance upfront mold investments with ongoing production costs. That’s why it’s crucial to explain injection moulding costs clearly and transparently.

At Manufyn, we simplify this process by offering end-to-end contract injection moulding solutions that help businesses manage costs effectively — from tooling design to mass production.

What is Injection Molding?

Injection molding is a manufacturing process used to produce plastic components by injecting molten material into a mold cavity. The process ensures precision, consistency, and scalability, making it ideal for industries like automotive, electronics, aerospace, and consumer goods.

There are various techniques under injection molding, each designed to suit different materials and applications:

Technical Injection Moulding

Used for high-performance components requiring extreme accuracy and durability.

Runner Injection Moulding

Focuses on optimizing material flow channels to reduce waste and improve part quality.

Polycarbonate Injection Moulding

Ideal for creating impact-resistant, lightweight parts used in electronics, medical devices, and automotive products.

For businesses looking to scale production efficiently, Manufyn provides contract injection moulding services that combine advanced machinery and expertise to deliver cost-effective, high-quality parts — whether it’s low-volume prototyping or large-scale manufacturing.

Pro tip: Choosing the right injection molding technique upfront helps minimize waste, optimize material use, and keep injection moulding costs under control.

Key Components of Injection Molding Costs

When calculating injection moulding costs, it’s important to understand what drives them. Whether you’re creating a small prototype or scaling to mass production, several factors influence your final injection moulding quote. Here are the key cost components:

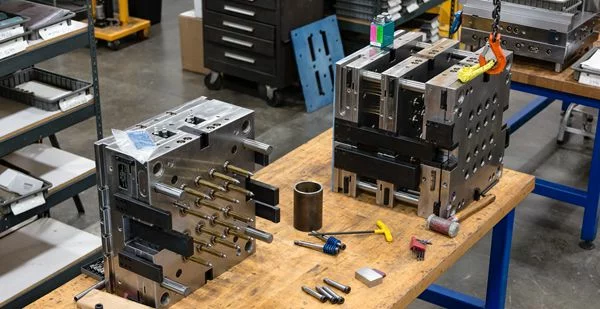

Tooling Costs (Mould Development)

- Tooling is the largest upfront investment in injection molding.

- Costs depend on mold size, cavity count, design complexity, and material choice.

- High-precision molds for technical injection moulding or polycarbonate injection moulding tend to cost more due to tighter tolerances.

Material Costs

- The type of plastic directly affects overall pricing.

- Using masterbatches for injection moulding can add color and functionality but also impact costs.

- Advanced materials like polycarbonate or glass-filled polymers are more expensive than standard plastics.

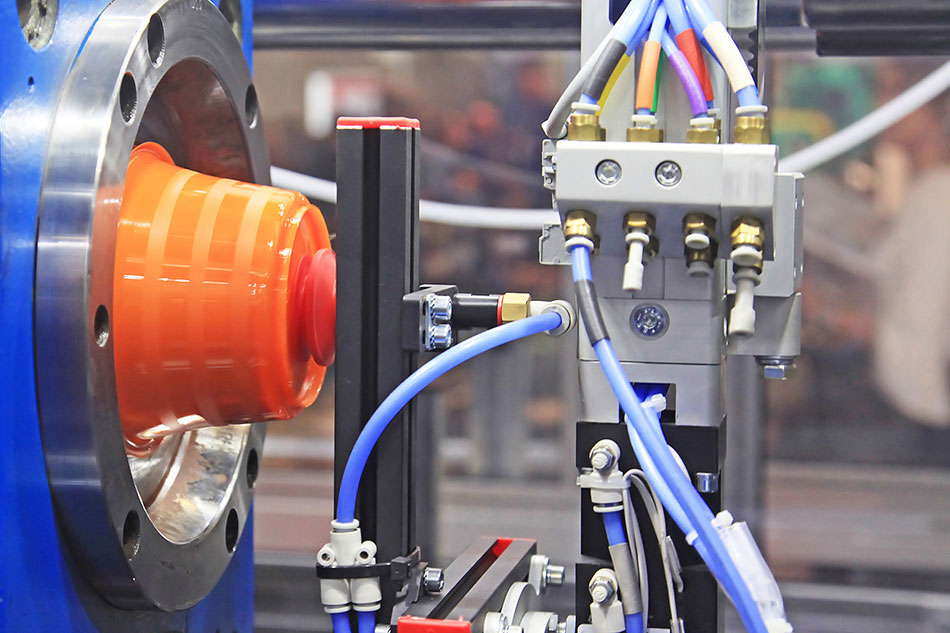

Production Cycle Time

- Shorter cycles reduce per-part costs but require runner injection moulding optimization to minimize waste and improve efficiency.

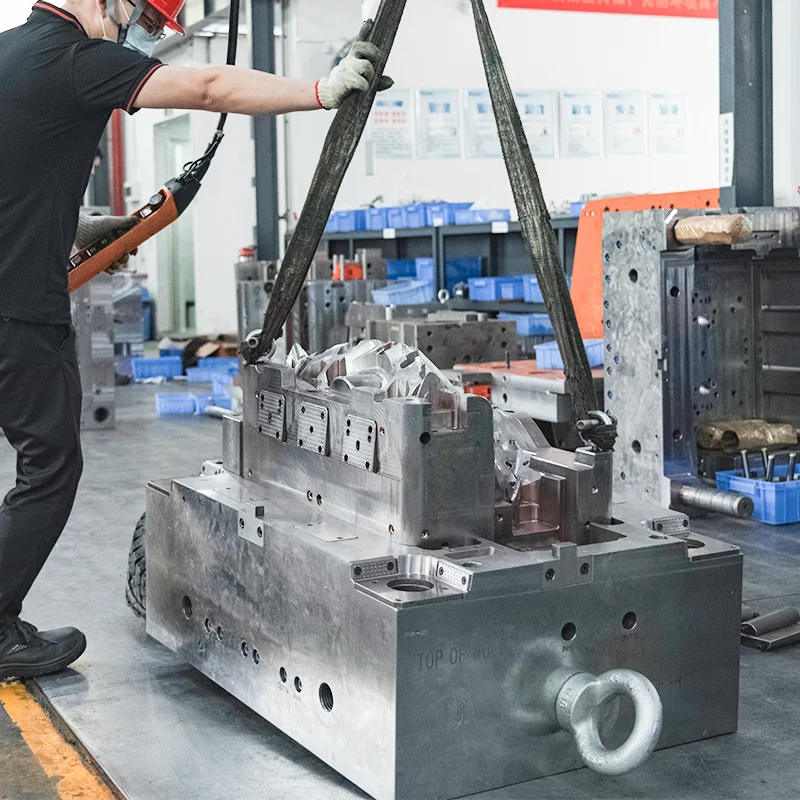

Labor & Overhead

- Skilled injection moulders are needed to manage tooling, material handling, and quality control.

- Modern automation can reduce labor dependency and lower long-term costs.

Finishing & Quality Assurance

- Surface finishing, texturing, and secondary operations add to the total cost.

- High-quality applications, such as aerospace or medical, demand more stringent quality checks.

Manufyn Advantage: At Manufyn, we streamline all these factors using advanced machinery and optimized production workflows to deliver the most competitive injection moulding quote without compromising on quality.

Tooling Costs vs. Per-Part Pricing

One of the biggest challenges in understanding injection moulding costs is differentiating between tooling expenses and per-part pricing.

Tooling Costs

- One-time investment made during the initial phase.

- Ideal for businesses planning high-volume production, as the cost gets distributed across thousands of parts.

- More complex molds, such as those for technical injection moulding, require a higher upfront cost but ensure precision and long-term durability.

Per-Part Pricing

- Refers to the recurring cost of producing each unit.

- Influenced by material selection, production volume, and cycle times.

- For smaller runs, per-part costs are higher since tooling expenses are spread over fewer parts.

Finding the Right Balance

For businesses new to injection molding, deciding between investing heavily in tooling or optimizing per-part costs can be tricky. That’s where Manufyn comes in. Our contract injection moulding services allow you to:

- Reduce tooling costs through optimized mold designs.

- Lower per-part pricing with efficient material usage and runner injection moulding techniques.

- Get accurate injection moulding quotes tailored to your production needs.

Pro tip: If you plan large-scale production, invest in high-quality tooling upfront. For low-volume batches, focus on optimizing per-part pricing instead.

Factors Affecting Injection Molding Costs in India

India has become a global hub for contract injection moulding due to competitive pricing and advanced manufacturing capabilities. However, several factors directly influence injection moulding costs. Understanding these will help you get a more accurate injection moulding quote and make smarter decisions:

Material Selection

Choosing the right material is critical.

Polycarbonate injection moulding and engineering plastics cost more but offer better strength, transparency, and durability.

Using master batches for injection moulding can add color, UV protection, or flame resistance, which affects pricing.

Part Complexity & Design

Intricate designs require technical injection moulding, which demands precise tooling and longer setup times.

Simple designs cost less, while parts with thin walls, multiple cavities, or intricate runners may need more advanced techniques like runner injection moulding.

Production Volume

Higher volumes reduce per-part pricing by spreading tooling costs over more units.

Low-volume batches can have higher costs per unit due to setup and material wastage.

Machine & Technology Used

Advanced, automated machines reduce manual intervention and errors, improving efficiency.

Specialized applications like spritzgiessen (precision German-style injection moulding) require high-end equipment, increasing costs but ensuring better quality.

Quality Control Standards

Industries like aerospace, automotive, and medical demand stricter quality checks, increasing operational expenses.

At Manufyn, our ISO-compliant processes ensure top-quality production at cost-effective pricing.

Manufyn Insight: By leveraging optimized runner injection moulding techniques and advanced tooling design, we help businesses reduce waste and achieve better cost efficiency without compromising quality.

How to Get an Accurate Injection Moulding Quote

Getting an accurate injection moulding quote is one of the most important steps before starting production. Many businesses make the mistake of sharing only basic dimensions or rough sketches, which often leads to cost miscalculations. To avoid surprises, you need to provide detailed information right from the beginning.

Provide Detailed Part Drawings

When approaching a manufacturer, always share proper 3D CAD files or detailed technical sketches. This helps the production team understand your exact design and ensures there are no assumptions. If your part requires technical injection moulding, precise measurements become even more critical for estimating tooling and production costs.

Choose the Right Material

Material selection plays a huge role in determining injection moulding costs. Whether you need polycarbonate injection moulding for high-strength components or standard thermoplastics for cost-effective parts, specifying your material upfront is essential. If you’re planning to use masterbatches for injection moulding to add colors or special properties, make sure to mention it, as this will influence the overall pricing.

Define Your Production Volume

The number of units you plan to produce has a direct impact on pricing. High-volume production typically lowers the per-part cost since tooling expenses are spread across thousands of parts.

On the other hand, low-volume batches may require a different cost strategy. At Manufyn, we offer contract injection moulding solutions that are optimized for both small and large runs, ensuring cost-effectiveness in every case.

Discuss Quality and Finishing Needs

If your parts require advanced finishes, texturing, or spritzgiessen-level precision, it’s important to communicate these requirements beforehand. High-quality finishing can add to the cost, but it ensures that the final product meets your exact expectations and industry standards.

Partner with the Right Injection Moulders

Choosing the right manufacturing partner can make all the difference. Many injection moulders provide quotes that leave out hidden expenses, leading to unexpected costs later. At Manufyn, we believe in complete transparency.

We provide customized injection moulding quotes tailored to your material, volume, and design needs, helping you plan your budget more accurately.

Why Choose Manufyn for Injection Moulding in India

Choosing the right injection moulding partner can make a huge difference in cost, quality, and delivery timelines. At Manufyn, we combine cutting-edge technology, industry expertise, and end-to-end support to deliver high-quality components at competitive prices.

Whether you need technical injection moulding, runner injection moulding, or polycarbonate injection moulding, we have the capabilities to handle projects of any scale and complexity.

End-to-End Contract Injection Moulding Services

From initial tooling design to mass production, we offer complete contract injection moulding solutions under one roof. This eliminates the need to coordinate with multiple vendors, saving you time, effort, and money.

Cost-Optimized Manufacturing

At Manufyn, we understand that injection moulding costs can be a deciding factor for your project. Our engineers focus on optimizing mold design, material usage, and runner systems to reduce wastage and bring down both tooling costs and per-part pricing without compromising quality.

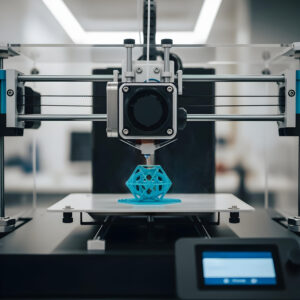

Advanced Machinery and Technology

We use the latest automated injection moulding machines capable of handling high-precision applications, including spritzgiessen techniques for ultra-fine parts. This ensures consistent quality across every batch and shorter lead times for your production needs.

Material Expertise

Whether it’s polycarbonate injection moulding, engineering plastics, or the use of masterbatches for injection moulding, our team helps you choose the most suitable material for your product’s function and cost targets.

Trusted by Leading Industries

Manufyn serves a wide range of industries, including automotive, electronics, medical devices, aerospace, and consumer goods. Our technical injection moulding expertise allows us to meet the strictest quality standards while delivering scalable production solutions.

When you choose Manufyn, you’re not just hiring an injection moulder — you’re partnering with a team dedicated to helping you optimize costs, enhance quality, and accelerate time-to-market.

Conclusion

Understanding injection moulding costs is essential when planning your production strategy. The balance between tooling expenses and per-part pricing can significantly impact your overall budget. By carefully selecting the right material, optimizing part design, and choosing the right production volume, you can make informed decisions that save both time and money.

At Manufyn, we simplify the entire process for you. From helping you explain injection moulding to providing a transparent, customized injection moulding quote, we take care of everything — from tooling design to large-scale contract injection moulding. Our expertise in technical injection moulding, runner injection moulding, and polycarbonate injection moulding ensures high-quality, cost-effective solutions for every industry.

If you’re looking for a reliable injection moulder in India who can deliver precision, efficiency, and affordability — Manufyn is your trusted partner.

Frequently Asked Questions

Injection moulding costs in India vary based on tooling complexity, material selection, and production volume. At Manufyn, we offer competitive pricing and provide a customized injection moulding quote tailored to your project needs.

Key factors include tooling design, per-part pricing, material choice, runner optimisation, and quality standards. Partnering with Manufyn helps you control these costs without compromising on quality.

To get a precise injection moulding quote, share detailed CAD drawings, material specifications, production volumes, and finishing requirements. Manufyn provides transparent, no-obligation quotes for all projects.

Tooling costs are a one-time investment for creating the mould, while per-part pricing covers the cost of producing each unit. At Manufyn, we help you balance both for the most cost-efficient solution.

Yes, polycarbonate injection moulding is typically more expensive than standard plastics because of its high strength and durability. However, Manufyn optimizes material usage to keep costs competitive.

Masterbatches for injection moulding are concentrated mixtures of pigments or additives used to enhance color and material properties. While they can slightly increase costs, they improve product quality and functionality.

Runner injection moulding involves optimizing material flow channels within the mould. By reducing wastage and improving cycle efficiency, Manufyn helps you lower per-part pricing and maximize material utilization.

Absolutely. Manufyn specializes in contract injection moulding, handling everything from tooling design to mass production. We deliver high-quality, cost-effective parts for multiple industries.

Industries like automotive, electronics, aerospace, medical devices, and consumer goods rely on injection moulding for producing high-quality components. Manufyn serves all these sectors with customized solutions.

Manufyn combines technical expertise, advanced machinery, and cost optimization to deliver precision-engineered parts at competitive prices. We ensure quality, efficiency, and transparency at every stage.

Get Your Free Injection Moulding Quote Today

Ready to bring your idea to life? Contact Manufyn today for an accurate, no-obligation injection moulding quote tailored to your design, material, and production needs.