To bring innovative products to market, speed is everything. Traditional prototyping methods, bogged down by expensive tooling and long lead times, can creativity and delay launch dates. Enter 3D printing a transformative technology that has turned the product development world on its head.

This isn’t just about creating models; it’s about accelerating innovation, slashing costs, and de-risking the entire journey from concept to customer.

For businesses, accessing this technology is key. A global manufacturing partner, understanding the power of 3D printing is your first step toward a faster, smarter development cycle.

What is 3D Printing and 3D Prototyping?

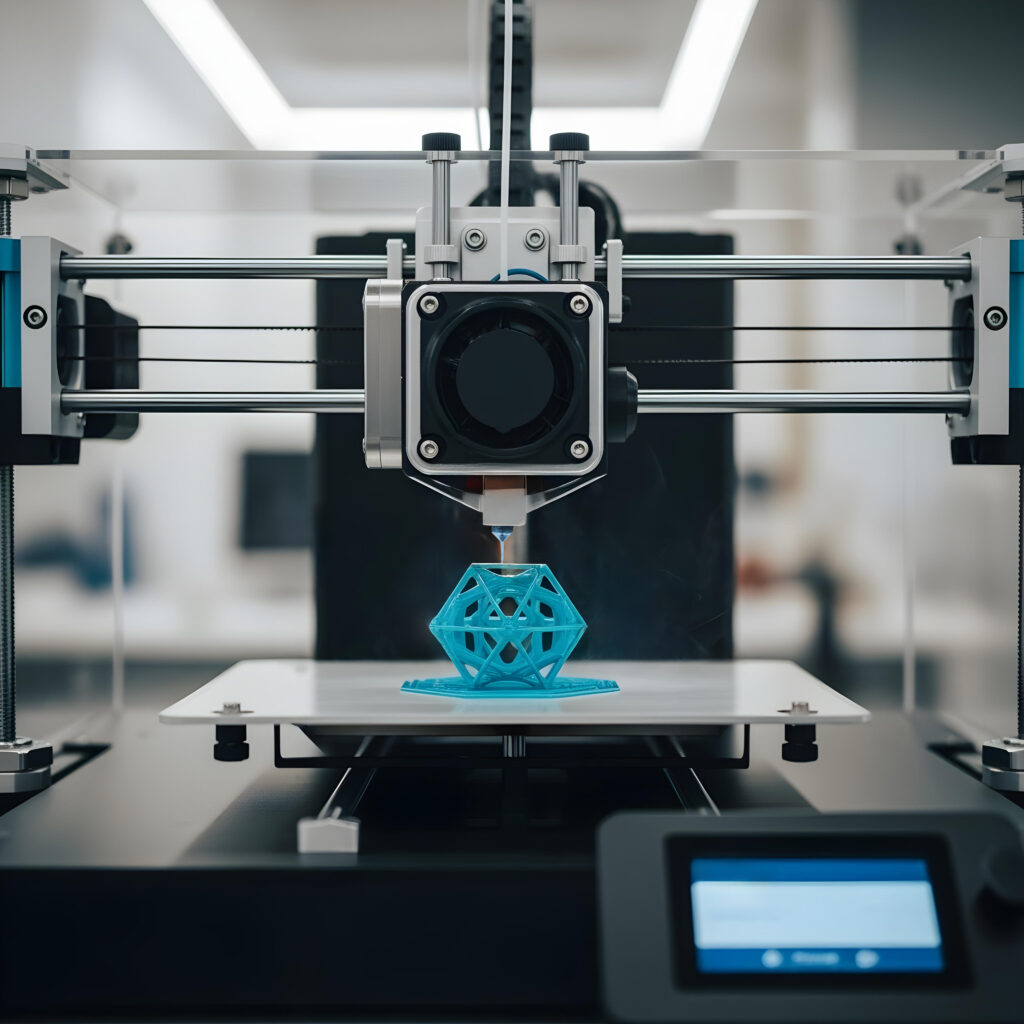

3D printing builds objects layer by layer from digital files. Unlike CNC machining that removes material, it adds only what’s needed reducing waste, cutting costs, and enabling unmatched design freedom. Since 1980s, it has evolved into advanced processes powering modern innovation.

3D printing prototyping is the crucial act of bringing that digital design into the real world as a tangible, testable object. This process allows designers and engineers to move beyond theory and validate their ideas in real-time.

The workflow is remarkably streamlined: create a 3D model in CAD software, prepare the file for printing, and let the printer build the part layer by layer.

This agility allows for rapid iteration; you can test a design, identify a flaw, tweak the CAD model, and have a new, improved version in your hands in a matter of hours or days, not weeks.

3D Printing Technologies for Prototyping

Not all 3D printing is created equal. Choosing the right technology is critical to achieving your prototype’s goals. Here’s a breakdown of the most common methods

Fused Deposition Modeling (FDM)

The most common and accessible technology. FDM printers extrude a heated thermoplastic filament to build parts layer by layer. It’s ideal for quick, low-cost concept models and basic functional testing.

Stereolithography (SLA)

Known for its exceptional surface finish and high resolution, SLA uses a laser to cure liquid resin into hardened plastic. It’s perfect for prototypes that require smooth surfaces, fine details, and aesthetic appeal, such as presentation models or intricate components.

Selective Laser Sintering (SLS)

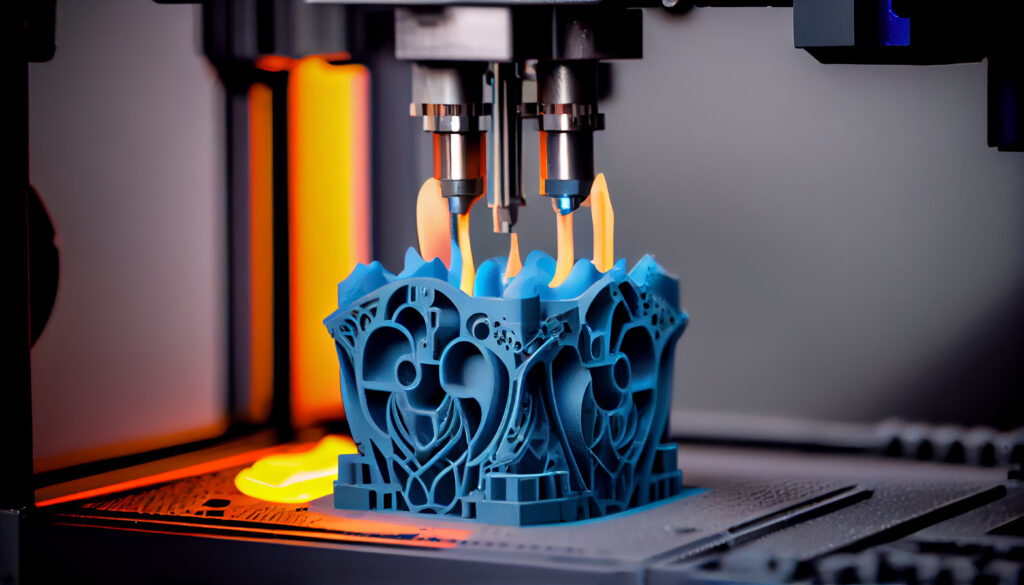

This technology uses a laser to fuse small particles of nylon powder. The major advantage? The surrounding powder acts as a support structure, allowing for the creation of complex, durable, and functional geometries that would be impossible with other methods. SLS parts are strong enough for rigorous functional testing under real-world conditions.

Multi Jet Fusion (MJF)

A step beyond SLS, MJF uses a fusing agent and a detailing agent across a bed of nylon powder, which is then fused by heating elements. It offers faster build times and more consistent mechanical properties throughout the entire part, making it excellent for functional prototypes and low-volume end-use production.

Book a call with Manufyn for manufacturing services.

Professional 3D Printing Service

While desktop printers are great for basics, professional 3D printing prototype services Manufyn provide access to industrial-grade machines, a wider range of engineering-grade materials, and expert knowledge. This is where a partner like Manufyn adds immense value.

Manufyn approaches 3D printing not as a standalone service, but as a key weapon in a broader manufacturing arsenal.

Our platform connects you with the optimal technology for your project whether it’s 3D printing for a complex, organic shape or CNC machining prototype service for a part requiring ultra-tight tolerances in metal.

Manufyn provides a consultative approach, analyzing your design to recommend the fastest, most cost-effective path to a high quality prototype, ensuring you never pay for more than what you truly need.

Manufyn’s Rapid 3D Prototype Manufacturing Service

The term “rapid prototyping” is put to the test with Manufyn’s global 3D printing network. Our rapid 3D printing prototype service is built to deliver functional parts within days, not weeks, helping you compress development cycles and get to market faster.

Whether your design team is in Atlanta, Amsterdam, or simply searching for a reliable “3D printing prototype service near me,” Manufyn ensures seamless access to world-class capabilities.

Just upload your CAD file to our secure portal, receive an instant quote, and we’ll manufacture and ship your parts from the most efficient location in our network.

This global yet local approach gives businesses everywhere on-demand access to industrial-grade prototyping without massive capital investment all while maintaining strict international quality and compliance standards.

Key Benefits of Integrating 3D Printing in Product Development

Integrating 3D printing into your product development process unlocks a wide range of advantages—from faster prototyping and reduced costs to unmatched design flexibility and improved product validation. Here’s how it transforms the way businesses innovate

Unmatched Speed & Iteration

Traditional manufacturing methods can take weeks to produce a single prototype. With 3D printing, you can test multiple design variations in just days or even hours, drastically shortening feedback loops. This speed allows teams to refine concepts quickly and bring products to market much faster.

Radical Cost-Effectiveness

By eliminating the need for expensive tooling, Molds, and setup costs, 3D printing is especially cost-effective for low-volume runs. Businesses of all sizes—from startups to large enterprises, can now access professional prototyping services without the heavy upfront investment.

Limitless Design Freedom

Unlike subtractive methods, additive manufacturing allows for the creation of complex geometries, intricate internal channels, and lightweight lattice structures that were once impossible or prohibitively expensive to make. This design freedom opens the door to more innovative, efficient, and high-performance products.

Early Flaw Detection & Risk Reduction

With 3D printed prototypes, designers and engineers can validate form, fit, and functionality at an early stage. Catching design flaws before full-scale production prevents costly mistakes, rework, and delays—saving both time and resources.

Enhanced Team Collaboration

Having a physical prototype in hand improves communication across design teams, engineers, stakeholders, and clients. It bridges the gap between digital models and real-world understanding, ensuring everyone is aligned before moving forward.

How to Reduce Prototyping Costs Without Compromising Quality

A common misconception in product development is that achieving high quality automatically comes with a high price tag. At Manufyn, we challenge that belief by leveraging smart strategies that optimize both cost and performance throughout the 3D printing and prototyping process

Design for Manufacturability (DFM) Analysis

Our expert engineers carefully review your CAD models to recommend design modifications that minimize material consumption and printing time. By eliminating unnecessary complexities, we ensure that your prototype or part is both cost-efficient and structurally sound.

Strategic Material Selection

Choosing the right material is key to balancing cost and performance. We guide you toward the most affordable material that still fulfils your strength, durability, and functional needs—helping you avoid the expense of over-engineering.

Technology Matching for Efficiency

Not every project requires the most expensive or advanced printing method. Instead of a one-size-fits-all approach, we select the most suitable 3D printing technology—whether it’s FDM, SLA, SLS, or another process—ensuring you get the perfect balance of precision, efficiency, and affordability.

By combining these strategies, Manufyn makes high-quality 3D printing prototypes accessible, affordable, and tailored to your exact needs, helping you bring products to market faster without overspending.

Plastic vs. Metal: How to Choose the Right Material ?

When it comes to 3D printing prototypes, the choice between plastic and metal often depends on finding the right balance between performance and budget. Each material serves a different purpose in the product development cycle.

Plastic 3D Printing

Plastic is the go-to option for most prototyping needs because it offers an excellent cost-to-performance ratio.

With material prices starting around $20/kg, plastic 3D printing is highly affordable and generally faster than metal. It’s ideal for form, fit, and functional testing, where speed and cost savings matter most.

Metal 3D Printing

Metal comes into play when prototypes must endure extreme stresses, high temperatures, or unique material requirements. While costs are significantly higher starting around $110/kg metal prototypes deliver unmatched durability and reliability.

They are essential in industries like aerospace, automotive, and medical, where precision and strength are critical and failure is not an option.

Manufyn provides transparent pricing for both plastic and metal 3D printing, ensuring you know exactly what you’re paying for. This clarity helps you make the most informed decisions for your project and budget, without hidden costs.

Conclusion

3D printing prototype services have irrevocably changed the game of product development. They provide the agility to innovate fearlessly, the efficiency to conserve resources, and the confidence to launch superior products.

The key to unlocking this potential lies in choosing the right manufacturing partner. Manufyn acts as your seamless extension, combining cutting-edge prototype machining services with a global network of 3D printing expertise.

We bring transparency, speed, and strategic guidance to your development process, ensuring that from the first prototype to the final production run, you are moving faster and smarter.

Frequently Asked Questions (FAQs) on 3D Printing Prototype Costs

What is 3D printing prototyping?

It’s the process of turning digital CAD designs into physical testable models, allowing faster design validation.

How much does a 3D printing prototype cost?

Costs can start as low as a few dollars for simple plastics and go up to thousands for complex metal parts.

How long does it take to get a 3D printed prototype?

Depending on complexity, prototypes can be ready in hours or a few days, much faster than traditional methods.

Which 3D printing technology is best for prototypes?

FDM works for quick and low-cost models, SLA for fine details, SLS/MJF for functional parts, and DMLS for metals.

Can 3D printing replace traditional manufacturing?

Not entirely—it’s ideal for prototyping and low-volume runs, but mass production is still best with traditional methods.

What industries benefit most from 3D printing prototypes?

Consumer electronics, automotive, aerospace, and medical sectors use it heavily for speed, testing, and precision.

How do I choose between plastic and metal for my prototype?

Use plastic for cost-effective testing and early validation; choose metal for high-strength, heat-resistant parts.does Manufyn reduce prototype costs?

By offering DFM analysis, smart material selection, and technology matching to avoid overspending.