Custom injection molding is one of the most reliable and scalable methods for producing high-quality plastic components tailored to specific requirements. Whether you’re a startup developing a new product or an established brand optimizing production, custom injection moulding services can transform your ideas into precise, durable, and repeatable parts.

Unlike traditional methods, custom injection molding services are not limited to standard designs — every mold is created to match your product’s unique geometry, material, and functional needs. From prototypes to mass production, this process ensures precision, consistency, and efficiency.

For businesses aiming to reduce manufacturing errors, shorten development time, and maintain cost-effectiveness, partnering with a professional custom injection molding manufacturer like Manufyn can make all the difference.

How Custom Injection Molding Works

Custom injection molding is a detailed process that involves converting raw plastic materials into final products through precision tooling and mold design. Here’s a breakdown of how it works and why it’s considered one of the most versatile manufacturing techniques.

1. Design and Concept Development

Every project begins with a product concept. Engineers and designers work together to develop a 3D model that defines the shape, size, and function of the final part. This stage ensures the design is optimized for manufacturability and material flow — a critical step in successful custom injection moulding.

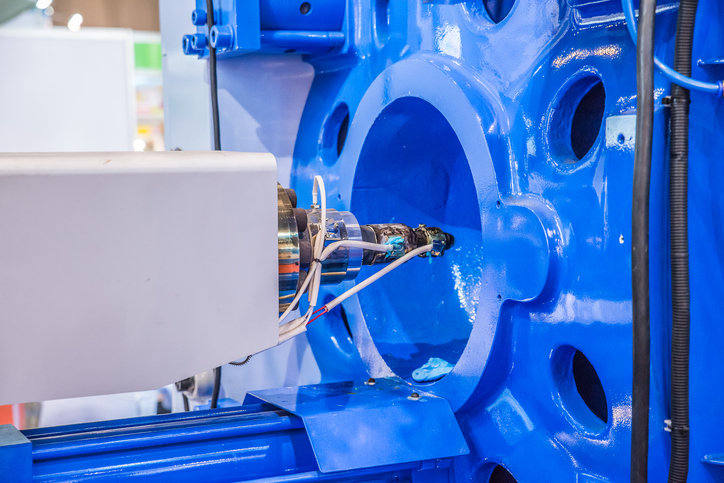

2. Mold Creation and Tooling

Once the design is finalized, custom molds (dies) are crafted from steel or aluminum. These molds define the shape and surface finish of the final product. A well-engineered mold reduces waste, improves precision, and ensures long-term repeatability — a hallmark of professional custom injection molding services.

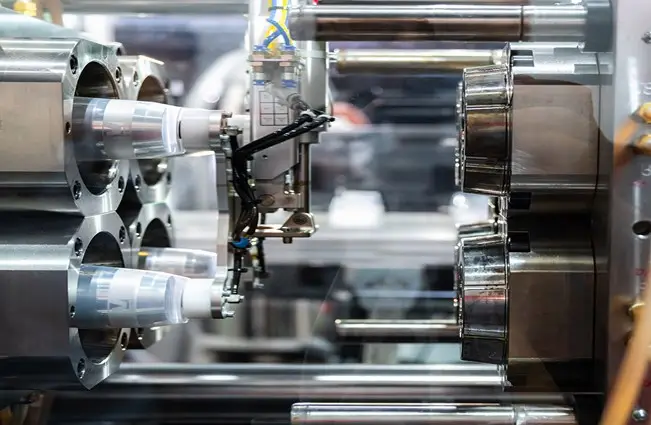

3. Injection and Cooling Process

In this step, molten plastic is injected into the mold cavity under controlled pressure using advanced custom injection molding machines. After cooling and solidifying, the mold opens, and the finished part is ejected — ready for finishing, assembly, or packaging.

4. Quality Testing and Finishing

Each product undergoes inspection for dimensional accuracy, strength, and surface finish. With custom injection moulding services, manufacturers can apply textures, colors, and coatings to achieve the exact aesthetic or functional result a client desires.

Why Businesses Choose Custom Injection Molding Services

Custom injection molding services are the backbone of modern manufacturing — offering precision, scalability, and consistency that few other methods can match. Whether it’s a small startup developing prototypes or a large enterprise scaling production, custom injection moulding provides the flexibility and control needed to create high-quality, durable plastic components efficiently.

The reasons businesses prefer custom injection molding go beyond just cost. It’s about achieving perfectly tailored results, maintaining product integrity, and optimizing time-to-market.

Precision and Consistency

Custom injection molding manufacturers use advanced machinery and CAD-based mold designs to ensure every part matches exact specifications. This level of accuracy makes the process ideal for industries where tolerance and fit are critical, such as automotive, medical devices, and consumer electronics.

Material and Finish Flexibility

From thermoplastics to high-performance polymers, custom injection moulding services support a wide range of materials, finishes, and colors. Businesses can choose materials based on strength, heat resistance, or aesthetic needs — creating both functional and visually refined products.

Cost-Effectiveness for Large Runs

Once molds are created, custom injection molding becomes highly efficient for medium to large production runs. Reduced waste, fast cycle times, and automation help lower per-unit costs, offering exceptional value without compromising on quality.

Common Challenges in Custom Injection Moulding (and How to Overcome Them)

While custom injection moulding delivers exceptional precision, it comes with its own set of challenges — from initial tooling costs to material selection and production timelines. Understanding these potential issues helps businesses make informed decisions and partner more effectively with a trusted custom injection molding manufacturer.

Design and Prototype Iterations

A poorly optimized product design can lead to flow issues, uneven cooling, or defects. Collaborating with manufacturers like Manufyn, who offer in-house design and prototyping, ensures your parts are optimized for moldability before full-scale production.

Choosing the Right Material

Selecting the right polymer for custom injection molding services is crucial. Factors like flexibility, temperature resistance, and durability must align with product performance goals. Experienced manufacturers guide clients in material selection to balance function and cost.

Balancing Quality and Cost

Tooling for custom injection molding can be expensive initially, but it pays off through long-term consistency and reduced production errors. Transparent cost analysis and scalable manufacturing solutions, as offered by Manufyn, help businesses maintain both quality and budget efficiency.

Production Lead Time

Mold fabrication and testing can extend project timelines. However, custom injection molding manufacturers that provide integrated design-to-production workflows — like Manufyn — can significantly reduce lead time without compromising precision.

Choosing the Right Custom Injection Molding Manufacturer

Selecting the right custom injection molding manufacturer can make or break your product’s success. While the technology and process are widely available, the expertise, precision, and service quality vary significantly between providers. The ideal partner doesn’t just mold plastic — they help you turn your vision into a scalable, manufacturable reality.

Expertise in Design and Engineering

A skilled custom injection moulding services provider goes beyond machinery. They understand part design, material behavior, and tooling dynamics. An experienced manufacturer can optimize wall thickness, eliminate sink marks, and enhance part strength — all during the design stage.

Material and Process Knowledge

Different industries require different grades of materials. A reliable custom injection molding manufacturer helps you choose polymers that balance durability, flexibility, and cost-efficiency. Whether it’s ABS for consumer goods or polycarbonate for high-impact applications, material selection plays a huge role in performance.

Scalability and Support

The best custom injection molding services are designed to grow with your business. From small batch prototypes to mass production, your partner should maintain consistent quality and delivery timelines. Also, ongoing support for mold maintenance and redesigns adds long-term value.

Quality Assurance and Certifications

Look for manufacturers that follow strict quality control standards, such as ISO-certified facilities. Consistency in every batch defines the difference between a standard supplier and a professional custom injection molding manufacturer.

How Manufyn Delivers End-to-End Custom Injection Molding Services

At Manufyn, we simplify the complexity of custom injection molding by offering a complete, integrated approach — from product concept to large-scale production. Our mission is to empower businesses with precision manufacturing, cost efficiency, and transparent collaboration.

Collaborative Design and Prototyping

Our team works closely with clients to refine their designs for manufacturability. Using 3D modeling, simulations, and rapid prototyping, we ensure every product is optimized before tooling — saving time and reducing costly reworks.

High-Precision Tooling and Mold Manufacturing

We develop custom molds using advanced CNC and EDM machining. Whether you require aluminum molds for short runs or hardened steel for mass production, our tooling expertise ensures accuracy and longevity — the foundation of successful custom injection molding services.

Advanced Machinery and Quality Control

Equipped with state-of-the-art custom injection molding machines, Manufyn maintains tight tolerances, consistent output, and flawless surface finishes. Every batch undergoes rigorous inspection and testing to meet global quality standards.

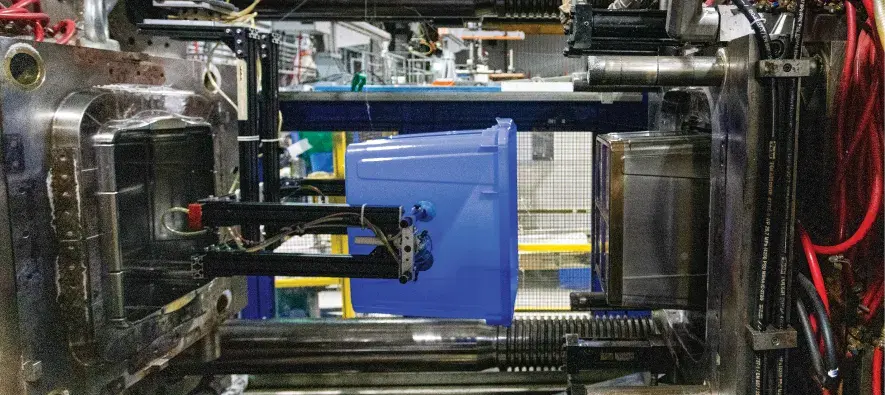

Flexible Production and Scalability

From pilot batches to full-scale production, our systems adapt to your needs. We specialize in custom injection moulding services that deliver efficiency, reliability, and flexibility across industries — whether it’s automotive components, industrial parts, or consumer products.

Sustainability and Innovation

Manufyn integrates sustainable practices by optimizing material usage and minimizing waste. Our R&D team continuously explores new materials and process innovations to make custom injection molding more efficient and eco-friendly.

Applications of Custom Injection Moulding Across Industries

The beauty of custom injection moulding lies in its adaptability — it’s a manufacturing process that fits almost every industry. Whether it’s small precision parts or large complex assemblies, custom injection molding services enable businesses to produce durable, high-quality components that meet both functional and aesthetic standards.

Automotive Components

From dashboards and clips to intricate engine bay parts, custom injection molding manufacturers help the automotive industry maintain strength, consistency, and lightweight performance. The ability to use reinforced polymers and multi-cavity molds ensures high-volume production without compromising accuracy.

Consumer Products and Electronics

For gadgets, appliances, and lifestyle products, custom injection moulding services offer the ideal balance between form and function. Sleek finishes, ergonomic designs, and reliable assembly fit make it a top choice for brands focused on usability and design appeal.

Medical and Healthcare Applications

Precision is non-negotiable in the healthcare sector. Custom injection molding services are used for producing syringes, diagnostic casings, surgical components, and more — all requiring biocompatibility, cleanliness, and dimensional stability.

Industrial and Packaging Solutions

From heavy-duty housings to specialized containers, custom injection molding provides durability and cost efficiency. Businesses benefit from quick mold changes, scalability, and material flexibility, making it ideal for both B2B and consumer packaging products.

Partnering with Manufyn for Custom Injection Molding Excellence

Choosing the right custom injection molding manufacturer is about more than machines — it’s about collaboration, precision, and trust. At Manufyn, we bring together cutting-edge technology, deep engineering expertise, and customer-centric service to deliver world-class custom injection moulding services for businesses of all sizes.

Comprehensive, End-to-End Services

From concept validation to large-scale production, Manufyn manages every stage of the custom injection molding process. Our in-house team assists with product design, mold creation, material selection, and manufacturing optimization to ensure that your product performs exactly as intended.

Technology-Driven Manufacturing

Our modern production units are equipped with high-precision custom injection molding machines, automated handling systems, and advanced quality testing setups. This enables us to maintain dimensional accuracy, surface finish consistency, and on-time delivery — every single time.

Material Expertise and Industry Coverage

Manufyn serves a wide range of industries including automotive, consumer electronics, healthcare, and industrial goods. Our team helps clients choose the most suitable polymers — from ABS and nylon to specialized engineering plastics — ensuring that performance, aesthetics, and cost align perfectly.

Why Clients Trust Manufyn

- Dedicated project engineers for personalized support

- Scalable solutions for both prototypes and production runs

- Strict quality assurance under ISO-certified standards

- Transparent pricing and quick turnaround times

With custom injection molding services from Manufyn, you don’t just get parts — you get precision-engineered solutions built to strengthen your brand and streamline your production pipeline.

Conclusion – The Future of Custom Injection Molding with Manufyn

Custom injection molding continues to redefine how modern businesses design and produce high-performance plastic components. From complex industrial parts to sleek consumer products, it offers unmatched precision, repeatability, and cost efficiency.

As markets evolve and competition tightens, working with an experienced custom injection molding manufacturer like Manufyn ensures that innovation never slows down. With a commitment to advanced technology, sustainable practices, and personalized service, Manufyn helps companies turn great ideas into production-ready solutions — faster, smarter, and more reliably.

Whether you’re looking to scale an existing product or prototype something entirely new, custom injection moulding services from Manufyn provide the expertise and infrastructure you need to succeed.

FAQs on Custom Injection Molding

Custom injection molding is a manufacturing process that injects molten plastic into a custom-designed mold to produce precise parts. The process is widely used for industrial, automotive, and consumer products that require consistent quality and high accuracy.

Unlike standard molding, custom injection molding services are tailored to your specific product design, material choice, and finish requirements. This ensures your parts meet exact performance and aesthetic expectations.

A reliable custom injection molding manufacturer offers design optimization, precise tooling, and consistent quality — all while reducing waste and production time. You also get better scalability and long-term mold performance.

Yes, custom injection moulding is ideal for intricate geometries, tight tolerances, and multi-cavity molds. With the right mold design and material choice, it can replicate even the most detailed features.

The timeline for custom injection molding depends on design complexity and material selection. Typically, mold creation can take 2–6 weeks, but rapid tooling and prototyping can shorten this window.

Industries like automotive, electronics, healthcare, and packaging rely heavily on custom injection molding manufacturers for parts that demand precision, consistency, and aesthetic appeal.

While custom injection moulding is most efficient for large runs, modern mold-making techniques and modular tooling can make it cost-effective even for short or pilot batches.

Small desktop DIY plastic injection machines are generally affordable, allowing beginners to try DIY injection molding without a large investment.

Manufyn provides complete custom injection molding services — from design and material selection to tooling and production. Their expertise ensures faster delivery, superior quality, and cost-efficient manufacturing.

You can start by sharing your design or concept with the Manufyn team. They’ll evaluate your requirements, suggest the best materials and tooling approach, and provide a free quote for your custom injection molding project.

Get Started with Manufyn Today

Get started with your next custom injection molding project — connect with Manufyn today for expert consultation and a tailored manufacturing quote.