Bringing a product idea to life is an exhilarating process, but it’s often shrouded in financial uncertainty. For engineers, designers, and startups, one of the most pressing questions is: “How much will a prototype cost?” When it comes to 3D printing, the answer isn’t a single number.

The cost of a 3D printing prototype can range from a few dollars for a simple plastic bracket to thousands for a complex, precision metal component. Understanding the variables that drive this cost is key to budgeting effectively and making smart decisions for your product development cycle.

What Are The Factors That Influence 3D Printing Prototype Cost

The final price of your 3D printed part is the sum of several interconnected variables. By optimizing each one, you can significantly control your overall expenditure.

The printing process itself is often the largest cost driver in 3D prototyping. Among the available technologies

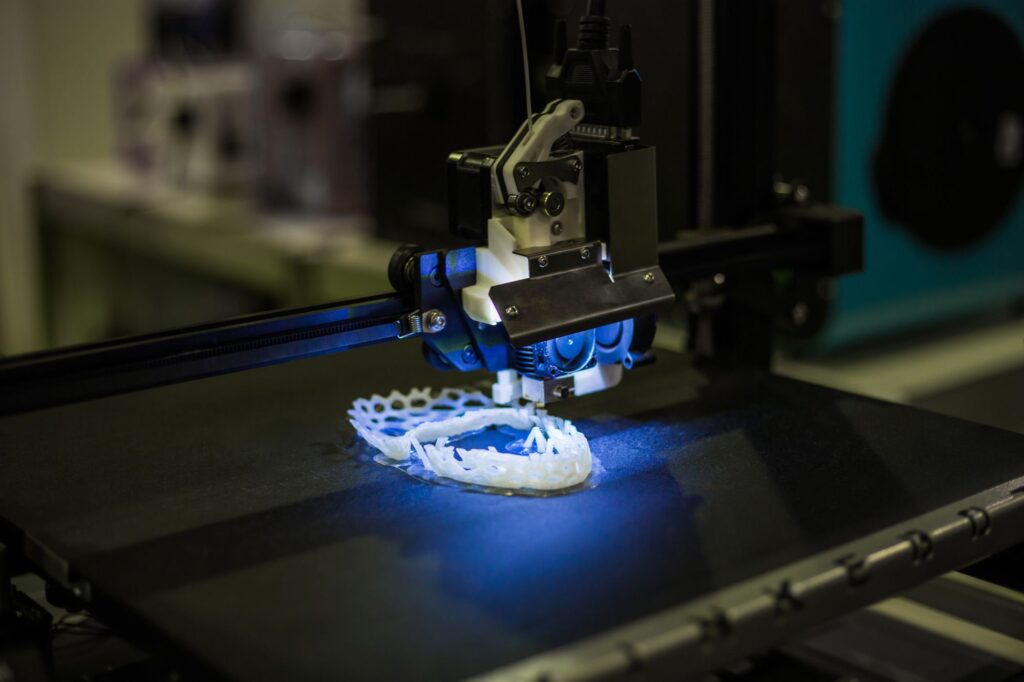

SLA/DLP (Stereolithography / Digital Light Processing)

SLA/DLP strikes a balance between cost and quality. These processes deliver excellent surface finish and fine detail at a moderate price point, making them ideal for visual prototypes, presentation models, and master patterns that need a polished appearance.

SLS/MJF(Selective Laser Sintering/ Multi Jet Fusion)

These technologies fuse nylon powder to create strong, functional parts without support structures. Priced higher than FDM or SLA but offer great value for durable components.

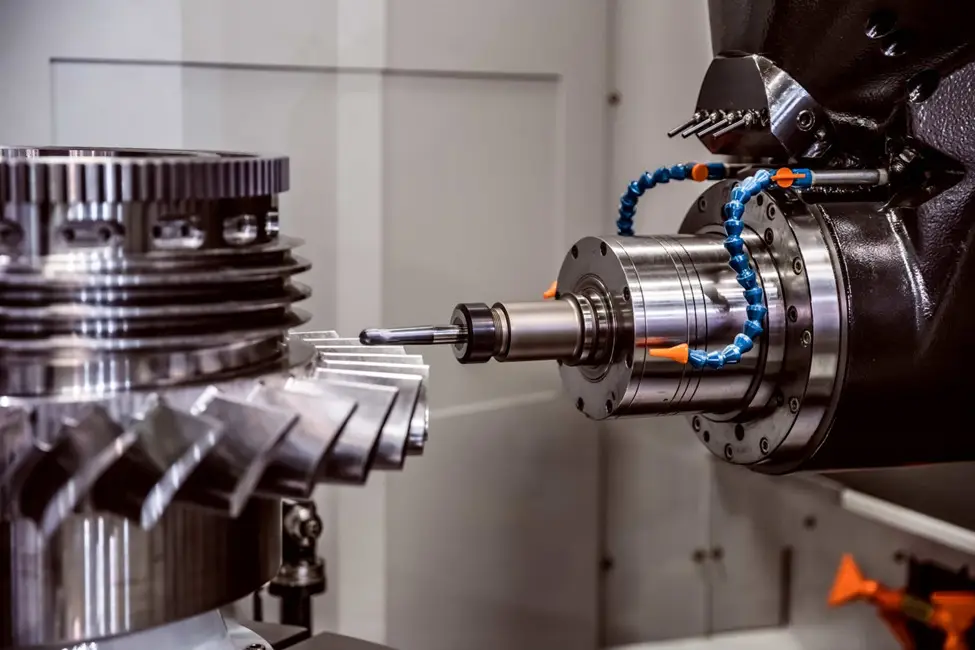

Metal 3D Printing (DMLS/SLM)

This is the premium tier. Metal 3D printing and similar services use high-power lasers to fuse metal powder, resulting in parts with exceptional strength and complexity, but at a significantly higher material and machine cost.

Material Selection

Material selection is one of the biggest cost drivers in 3D printing prototypes. Plastics like PLA and ABS are very affordable, while engineering-grade options such as Nylon (PA), ULTEM (PEI), or transparent resins are more expensive due to their advanced properties.

Part Size and Volume

Most services calculate a “build cost” based on the volume of material your part occupies (XYZ dimensions) and the total volume of parts in a single print job. Larger parts consume more material and more machine time, increasing the cost.

Part Complexity and Design

Intricate designs with fine details, overhangs, and complex geometries require more precise printing, potentially slower print speeds, and more support material (which is later discarded). A simpler, more optimized design is almost always cheaper to produce.

Post-Processing and Finishing

Post-processing and finishing also add to prototype costs. Steps like support removal, sanding, polishing, painting, dyeing, or specialized coatings all increase the final price depending on the level of detail and finish required.

Navigating these factors can be challenging, but Manufyn makes it simple. With vetted experts and instant, transparent quotes, we help you make cost-effective decisions without sacrificing quality.

Technologies Used at Manufyn for 3D Printing Prototypes

To understand cost, you must understand the tools available. Manufyn’s network leverages a full spectrum of industrial-grade 3D printing technologies to match the right process to your project’s requirements and budget.

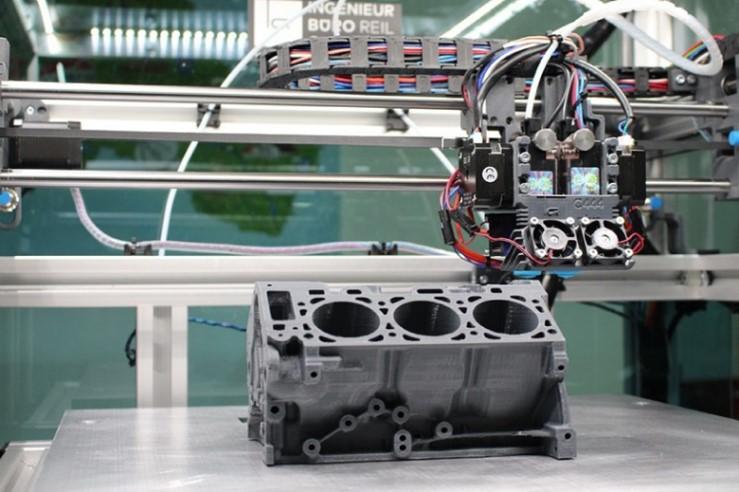

Fused Deposition Modeling (FDM)

Our workhorse for rapid, low-cost conceptual models. We use production-grade FDM printers with materials like ABS, ASA, and PETG, which offer better temperature and chemical resistance than desktop alternatives.

Stereolithography (SLA)

For projects requiring impeccable detail and surface smoothness, SLA is our go-to. It’s unparalleled for creating molds, patterns, and prototypes where visual appeal is critical. We offer a range of resins, from standard to castable and high-temperature.

Selective Laser Sintering (SLS) & Multi Jet Fusion (MJF)

When you need functional prototypes that mimic the strength and durability of injection-moulded parts, we turn to SLS and MJF. These nylon-based processes produce robust, complex parts without supports, reducing post-processing time and cost.

Direct Metal Laser Sintering (DMLS)

For the ultimate in performance, our metal 3D printing capabilities allow for the creation of complex, fully dense metal parts from alloys like Aluminum AlSi10Mg, Stainless Steel 316L, and Titanium Ti6Al4V.

By offering this range in-house, Manufyn can provide unbiased advice on the most cost-effective technology for your specific application.

How Does 3D Printing Prototype Cost Differ Across Industries?

The cost of a 3D printing prototype is not just about the material—it also depends on compliance, certifications, and precision requirements, which vary widely across industries.

Consumer Electronics

Typical Requirements: High aesthetic finish, snap-fit assemblies, and precise tolerances for housings.

Cost Impact: Moderate to High. Often requires SLA for smooth surfaces or MJF for strength, along with painting and finishing for final looks.

Automotive

Typical Requirements: Functional durability, heat resistance (especially for under-hood parts), and certified materials.

Cost Impact: Moderate to High. Utilizes engineering plastics, such as SLS or MJF, and occasionally metal printing (DMLS) for performance testing.

Aerospace & Defence

Typical Requirements: Extreme strength, lightweight structures, full traceability, and strict certifications (e.g., NADCAP, AS9100).

Cost Impact: Very High. Relies heavily on metal DMLS printing, with extensive post-processing and compliance documentation.

Medical & Dental

Typical Requirements: Biocompatible materials (Class I/II), sterilizability, and high precision (e.g., surgical guides or implants).

Cost Impact: High. Needs certified materials such as medical-grade nylon or titanium, along with validated processes.

Leading 3D Printing Prototype Service Models

When sourcing prototypes, companies often compare leading platforms to evaluate pricing, turnaround time, available technologies, material options, and overall reliability. This comparison helps them choose the right partner that balances cost-efficiency with high-quality results.

Manufyn strikes a balance between these two models. We leverage a curated, vetted network of partners, not an open marketplace. This ensures consistent, high-quality results you can rely on.

Our focus is on providing a personalized service including expert DFM feedback and transparent, competitive pricing, especially for low to mid-volume prototype runs and bridge to production parts. We act as your dedicated manufacturing partner, not just a transactional portal.

Manufyn’s Approach: Standard Quality at a Reasonable Cost

At Manufyn, we believe high-quality prototypes shouldn’t require a premium price tag. Our philosophy for delivering exceptional value is built on four key pillars:

Design for Manufacturability (DFM) Analysis

Before a single part is printed, our engineering team reviews your design. We identify potential issues that could increase cost or cause print failures and suggest modifications to optimize for your chosen technology. A small, free design change can often lead to massive cost savings

Technology Matching

We don’t believe in a one-size-fits-all approach. We will recommend the most economical technology that meets your functional requirements.

Transparent, Upfront Pricing

Our automated quoting platform provides instant price estimates based on your uploaded CAD file, material, and finish selections. There are no hidden fees, allowing you to make informed financial decisions immediately.

Vetted Partner Network

Unlike open marketplaces, we pre-qualify every manufacturing partner in our network for quality, equipment, and certifications. This reduces your risk and ensures you get reliable, consistent parts without the hassle of vetting suppliers yourself.

This holistic approach allows us to control costs at every stage of the process, passing the savings on to you while guaranteeing a product that meets the highest standards.

Why Manufyn Is Your Partner for Cost-Effective 3D Printing Prototypes

Cost is a function of technology, material, size, and the required level of finish and certification. A partner like Manufyn offers a compelling alternative: the perfect blend of automated efficiency and human expertise.

We provide the transparency and speed of a digital platform with the strategic guidance of an engineering consultant.

Upload your CAD model to Manufyn today and see how our approach to 3D printing prototype cost delivers unparalleled value without compromising on quality.

Frequently Asked Questions (FAQ) on 3D Printing Prototype Costs

A simple plastic prototype can cost $10–$50, while complex metal parts may run into thousands.

Technology, materials, part size, design complexity, and finishing are the main cost drivers.

FDM is the cheapest option, ideal for quick prototypes and simple design validation.

Yes, SLA offers finer detail and smoother surfaces but at a higher cost than FDM.

Yes, due to costly machines and materials, but they provide unmatched strength and durability.

Simplify your design, choose the right technology, and optimize material use effectively.

Functional nylon prototypes usually range between $100–$500, depending on size and detail.

Yes, steps like polishing, painting, or coating add labor and raise the final price.

Consumer parts are moderate, while aerospace, defense, and medical require higher-cost certifications.

By offering transparent pricing, vetted partners, and expert design-for-manufacturing feedback.