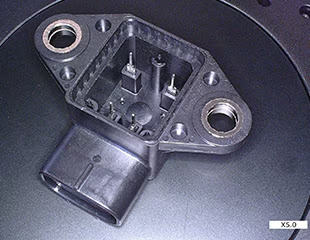

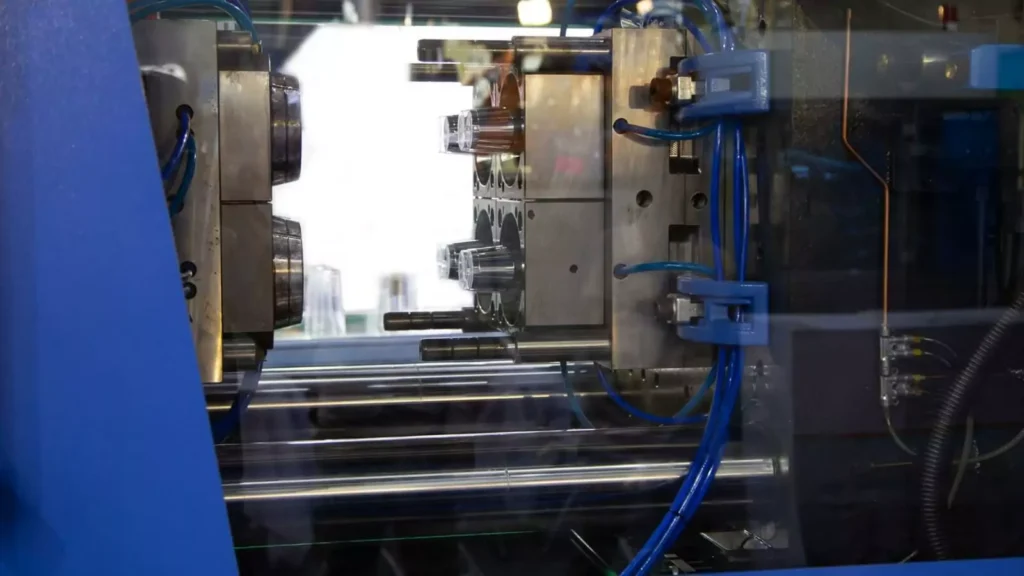

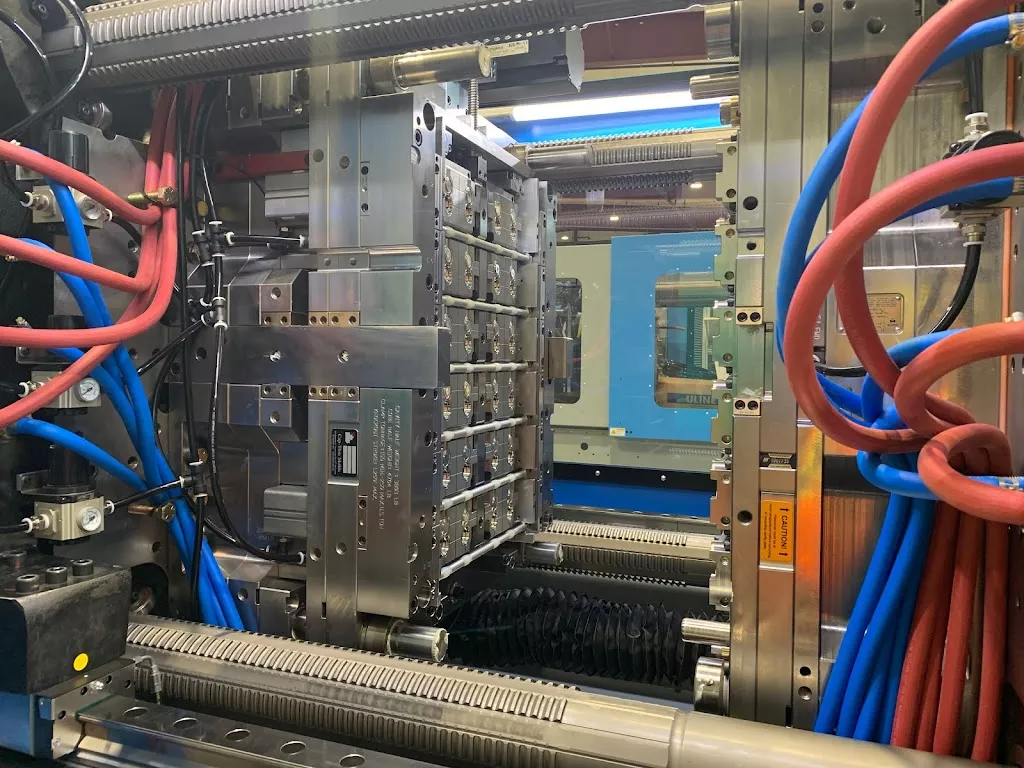

Injection moulding faults are one of the biggest challenges in modern manufacturing, often leading to wasted material, increased costs, and production delays. To better understand why these issues occur, it’s important to first define injection moulding: it is a process where molten material, usually plastic, is injected into a mould, cooled, and then ejected as a finished part.

The injection moulding procedure involves four main stages, melting the raw material, injecting it into a mould, cooling, and finally ejecting the product. While efficient and scalable, even minor deviations in temperature, pressure, or tooling can create defects. For manufacturers, preventing these injection moulding faults is essential to ensure consistent quality and reduce rework.

Why Injection Moulding Defects Occur

Every manufacturer has faced injection moulding faults at some stage of production. These defects don’t appear randomly — they result from specific problems in materials, machines, or processes. By understanding the root causes, companies can take proactive steps to minimize risks.

Material Issues

The choice and preparation of raw material directly impact part quality. If plastics are not dried properly or contain impurities, the result can be voids, warpage, or brittle parts. Specialized materials like PU injection moulding or injection moulding of ceramics are even more sensitive to preparation, requiring strict control to avoid contamination.

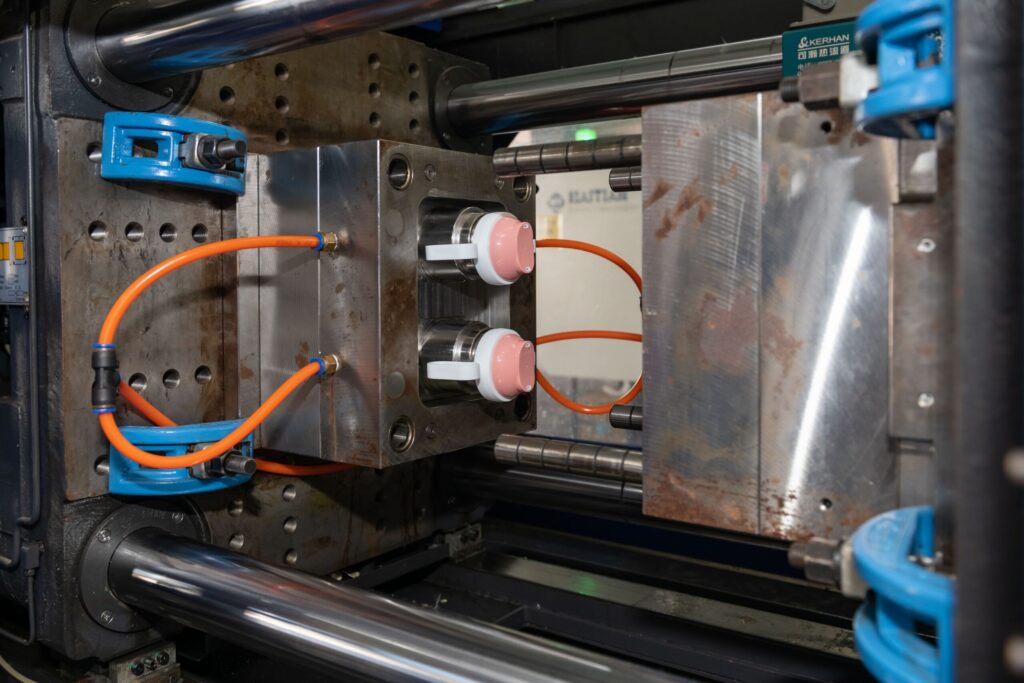

Tooling Errors

The mould itself plays a critical role. Poor design, wear and tear, or incorrect venting often lead to recurring injection moulding faults such as flash, weld lines, or short shots. Regular maintenance and design validation are essential to prevent these issues.

Machine Calibration

Incorrect settings in the injection moulding procedure — pressure, injection speed, melt temperature, or cooling time — often cause defects like sink marks or voids. Even small deviations can multiply problems across thousands of parts.

Human & Process Factors

Operator skill levels and process monitoring also influence outcomes. A lack of attention to cycle times or improper troubleshooting can make faults worse.

Beyond quality concerns, defects have a direct financial impact. Rejected parts drive up material waste, rework costs, and production delays — all of which increase injection moulding quotes. Whether working with local suppliers or outsourcing to competitive markets such as injection moulding Australia, avoiding these faults is key to achieving cost efficiency and timely deliveries.

Top 10 Injection Moulding Faults (Defects) and Their Prevention

Injection moulding faults reduce yield, increase scrap, and raise production costs. Below are the ten most common faults, explained with clear, actionable prevention steps.

1. Short Shots

What it is: The cavity does not fill completely; parts are incomplete or have missing sections.

Causes: Low injection pressure, insufficient melt temperature, blocked vents, restrictive gates, or overly fast cooling.

How to spot it: Short ribs, incomplete bosses, or a distinct line where the melt stopped.

Prevention:

- Increase injection pressure or hold pressure.

- Raise melt temperature moderately to lower viscosity.

- Enlarge gate size or change gate location for better flow.

- Improve venting to avoid trapped air.

- Use mold flow simulation during design.

Notes: During injection moulding prototypes, confirm fill with trial runs to avoid costly tool changes later.

2. Burn Marks

What it is: Dark or charred areas on the part surface, often near gates or thin sections.

Causes: Trapped air, excessive melt temperature, slow venting, or too-fast injection speed.

How to spot it: Localized dark spots, often glossy and brittle.

Prevention:

- Improve venting and runner design.

- Lower melt temperature or reduce injection speed.

- Use multi-stage injection profile to avoid local overheating.

- Check for degraded or contaminated material.

Notes: Materials used in pu injection moulding can scorch if temperatures are too high; adjust process windows accordingly.

3. Weld Lines (Knit Lines)

What it is: Weak lines where two flow fronts meet, often with visible seam or reduced strength.

Causes: Low melt temperature, low injection speed, gate design that creates separate flow fronts, or poor venting.

How to spot it: A visible seam or line, often with weaker mechanical properties.

Prevention:

- Increase melt and mold temperature to improve flow cohesion.

- Reposition gates to avoid meeting flow fronts in stressed areas.

- Increase injection speed and pack pressure.

- Use surface treatments or additives to improve bonding.

Notes: For structural parts in automotive or aerospace, address weld lines in design stage and validate during prototyping.

4. Flash

What it is: Excess material along parting lines or around features caused by molten polymer escaping the cavity.

Causes: Excessive injection pressure, worn or mismatched mold halves, inadequate clamp force, or poor mold design.

How to spot it: Thin, unwanted fin-like projections on part edges.

Prevention:

- Reduce injection pressure and optimize pack/hold phases.

- Inspect and service mold fit (ensure parallelism and clamp force).

- Add proper venting and improve parting surface finish.

- If flash persists, adjust mold steel or add locating features.

Notes: Flash increases post-processing cost and can affect assembly tolerances; include allowance in injection moulding quotes.

5. Sink Marks

What it is: Depressed areas on the surface, usually over thick sections where material shrank during cooling.

Causes: Inadequate packing, thick wall sections, slow cooling or low pack pressure.

How to spot it: Localized hollow or dimple on the surface, often near boss or rib intersections.

Prevention:

- Reduce wall thickness and design for uniform section thickness.

- Increase pack/hold pressure and extend hold time.

- Improve cooling in the mold (add cooling channels).

- Use higher glass-transition temperature grades or fillers to reduce shrink.

Notes: Early prototyping helps identify sink-prone geometry before machining final tools.

6. Warpage

What it is: Distortion of the part after ejection due to uneven shrinkage or internal stresses.

Causes: Non-uniform wall thickness, uneven cooling, incorrect packing, or anisotropic material behavior.

How to spot it: Twisted, bowed, or dimensionally unstable parts that fail to meet tolerances.

Prevention:

- Design uniform wall thickness and symmetric geometry.

- Balance cooling channels to equalize mold temperature.

- Optimize pack pressures and cooling time in the injection moulding procedure.

- Consider material with lower shrink rates or add reinforcements.

Notes: Warpage risk increases for larger or long-span parts. Mold flow analysis and trial runs help predict deformation.

7. Voids & Air Traps

What it is: Hollow cavities inside the part caused by trapped air or gas.

Causes: Inadequate venting, rapid fill, moisture in material, or excessive material shrinkage.

How to spot it: Soft or hollow-sounding areas; cross-sectioning reveals internal voids.

Prevention:

- Improve venting and gating design.

- Lower injection speed to allow air to escape.

- Dry hygroscopic materials properly before molding.

- Use pack pressure to compress and fill void-prone regions..

Notes: Voids reduce mechanical strength. For injection moulding of ceramics, careful powder-binder control is essential to avoid porosity.

8. Jetting

What it is: Snake-like lines or streaks caused by the melt jetting into the cavity and cooling before contacting cavity walls.

Causes: High injection speed, inadequate gate design, or sudden change in flow direction.

How to spot it: Curved, worm-like flow patterns typically near gate exits or complex channels.

Prevention:

- Reposition or redesign gates to promote smooth flow.

- Reduce injection speed and adjust hold profile.

- Use engineered gate shapes (tapered or fan gates) to distribute flow.

Notes: Jetting is common on glossy parts; early injection moulding prototypes can reveal jetting susceptibility.

9. Flow Lines (Flow Marks)

What it is: Aesthetic streaks or wavy patterns on part surfaces caused by variations in flow or temperature.

Causes: Non-uniform melt temperature, variable injection speed, or abrupt changes in cross-section.

How to spot it: Visible lines following flow direction; sometimes a change in gloss or color.

Prevention:

- Maintain consistent melt and mold temperatures.

- Smooth transitions in geometry to avoid sudden flow changes.

- Optimize gate location to reduce flow length.

- Use high-quality, homogenized resin blends to improve flow appearance.

Notes: Injection film processes can mask or accentuate flow lines; test finishes during sampling.

10. Discoloration

What it is: Color variation or spotting on the part surface.

Causes: Contaminated resin, overheating, carbonization, pigments not dispersed, or moisture.

How to spot it: Uneven color, streaks, or dark spots across surface.

Prevention:

- Ensure strict material handling and drying procedures.

- Maintain melt temperatures within recommended ranges.

- Use consistent pigment batches and proper masterbatch mixing.

- Clean barrel and screw regularly to avoid burn-in.

Notes: Discoloration is especially critical for consumer goods. For specialty processes such as injection film, choose compatible films and adhesives to avoid color mismatch.

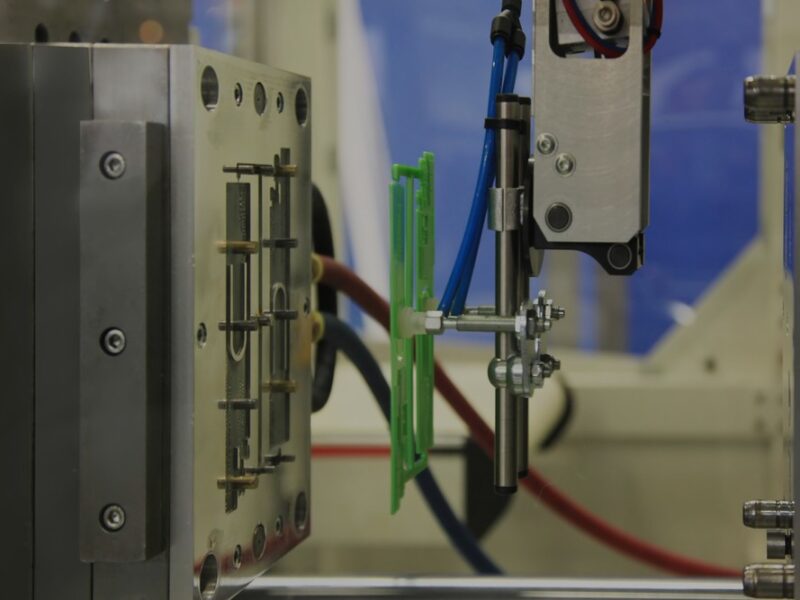

Injection Moulding Prototypes & Testing for Defect Prevention

Injection moulding prototypes are a crucial step in ensuring your production runs smoothly and defect-free. Before committing to full-scale manufacturing, creating a prototype allows engineers and designers to test the part’s geometry, material behavior, and overall functionality. This early-stage testing helps identify common injection moulding faults, such as warpage, sink marks, or weld lines, before they become costly problems.

Prototyping also allows experimentation with specialized materials. For example, PU injection moulding is widely used for flexible components, while injection moulding of ceramics is employed in high-precision, heat-resistant applications. Testing prototypes in these materials ensures that the final production process is optimized for quality and durability.

By catching defects early, prototyping reduces the risk of expensive rework, lowers scrap rates, and shortens lead times. Companies can also simulate real-world conditions, checking how parts perform under stress, temperature changes, or mechanical loads. This predictive approach is particularly valuable for complex designs or new materials, providing peace of mind before moving to large-scale production.

Getting Accurate Injection Moulding Quotes

Accurate injection moulding quotes are essential for cost planning and project budgeting. Defects like short shots, flash, or warpage directly impact material usage, machine time, and labor, which in turn affect the final cost. By understanding how these injection moulding faults influence production, manufacturers can provide more precise quotes, avoiding unexpected expenses later.

When requesting or preparing a quote, several factors are considered: material type, part complexity, production volume, and the type of injection moulding process (standard plastics, PU injection moulding, or injection moulding of ceramics). Prototype testing further ensures that the quoted process will be reliable and defect-free, reducing risk for both manufacturers and clients.

For businesses sourcing globally, looking at suppliers like injection moulding Australia can provide a benchmark for cost, quality, and lead time. Comparing multiple quotes while factoring in potential defects and material considerations helps make informed decisions and ensures a smoother production process.

Ultimately, accurate quotes are not just about price—they are a reflection of production efficiency, defect prevention strategies, and reliable supply chain planning.

Advanced Materials & Techniques in Injection Moulding

Modern injection moulding has evolved far beyond standard plastics, with advanced materials and techniques helping manufacturers achieve higher precision, durability, and aesthetic appeal. Using specialized materials like PU, ceramics, or bio-plastics allows engineers to meet unique design requirements and reduce common injection moulding faults.

PU injection moulding is ideal for flexible, shock-absorbing parts, such as seals, gaskets, and ergonomic components. Its adaptability ensures that defects like warpage or sink marks are minimized when process parameters are optimized.

Injection moulding of ceramics caters to high-heat and high-precision applications, such as electrical components and medical devices. Proper tooling and controlled injection parameters prevent cracks, voids, or surface imperfections, ensuring a defect-free outcome.

An emerging technique, injection film moulding, is used for specialized applications requiring decorative or protective layers on parts. By integrating this method, manufacturers can achieve enhanced surface finish and functionality without compromising structural integrity.

By leveraging these advanced materials and techniques, companies not only reduce defect rates but also expand their product capabilities, staying competitive in industries where quality and precision are critical.

Where Manufyn Adds Value in Preventing Injection Moulding Faults

While most manufacturers struggle with recurring injection moulding faults, Manufyn takes a proactive approach. Our process combines design validation, rapid prototyping, and strict quality checks to ensure that defects are minimized before mass production.

Design for Manufacturability (DFM): Our engineers run detailed simulations to identify risks like weld lines, sink marks, or warpage before the first tool is cut.

Prototype Validation: We produce injection moulding prototypes to test complex parts — whether it’s PU injection moulding, injection moulding of ceramics, or advanced plastics.

Global Benchmarking: With experience in both Indian and international markets, including injection moulding Australia standards, we deliver consistent, export-ready quality.

Cost Transparency: Our accurate injection moulding quotes include allowances for testing and defect prevention, so you don’t get hit with hidden rework costs.

End-to-End Support: From tooling design to optimized production runs, Manufyn ensures your parts are defect-free, consistent, and production-ready.

By partnering with Manufyn, you reduce downtime, eliminate costly rework, and achieve faster time-to-market with high-quality plastic components.

Conclusion

Injection moulding is a versatile and widely used manufacturing process, but even minor injection moulding faults can lead to increased costs, delays, and compromised product quality. By understanding the top 10 defects—from short shots and burn marks to warpage and discoloration—manufacturers can implement effective prevention strategies.

Prototyping, especially with specialized materials like PU injection moulding or injection moulding of ceramics, plays a critical role in catching defects early, ensuring a smoother transition to full-scale production. Accurate injection moulding quotes and a careful evaluation of suppliers, including international options like injection moulding Australia, further support cost-effective and reliable manufacturing.

Ultimately, partnering with an experienced injection moulding provider guarantees defect-free, high-quality products while optimizing production efficiency. Investing in quality control, advanced materials, and precise planning ensures that every part meets design expectations and delivers maximum value.

FAQs on Injection Moulding Defects

Common defects include short shots, burn marks, weld lines, flash, sink marks, warpage, voids, jetting, flow lines, and discoloration.

Defects arise due to material inconsistencies, poor tooling design, machine calibration issues, or operator errors.

Prototyping allows testing of part geometry, material behavior, and process parameters before full-scale production, reducing defect risk.

PU injection moulding is ideal for flexible, durable components like seals, gaskets, and ergonomic parts.

Yes, injection moulding of ceramics is used for high-precision, heat-resistant parts in industries like medical and electronics.

Defects increase material usage, machine time, and scrap rates, impacting overall costs and quoted prices.

Injection film adds decorative or protective layers on parts without compromising structural integrity, improving surface finish and functionality.

Proper mold design, optimized cooling, and controlled injection pressure help prevent warpage and sink marks.

Comparing global suppliers ensures competitive pricing, quality assurance, and reliable lead times for defect-free production.

Combining prototyping, advanced materials, precise machine calibration, and experienced suppliers ensures high-quality, defect-free parts.